You are looking for information, articles, knowledge about the topic nail salons open on sunday near me how to reduce rpm of 3 phase motor on Google, you do not find the information you need! Here are the best content compiled and compiled by the Chewathai27.com team, along with other related topics such as: how to reduce rpm of 3 phase motor 3 phase motor speed controller, speed control of 3-phase induction motor pdf, induction motor speed, 3 phase induction motor speed formula, voltage frequency control of induction motor, speed control of ac motor pdf, low speed 3 phase motor, Three-phase motor

The load to be driven by the shaft will often require a different speed or torque or will require the transmission of power to an adjacent shaft. Reducing RPM can be accomplished by using two or more pulleys and belts to transmit and change the speed of rotation.Get a pump driven by a universal motor, (electric tools type, with brushes) and you’ll be able to use voltage variation to get variable speed. Or get a DC driven pump (as used in small ships) and you can also use this cheap electrical variable speed method.Yes it is possible but not necessarily adviceable. You gave a bit limited information, so I am not sure of your application. Assume it was an induction machine, designed for 50 Hz and 1400 rpm. (Often speed of these machines are 1450 rpm for nominal power).

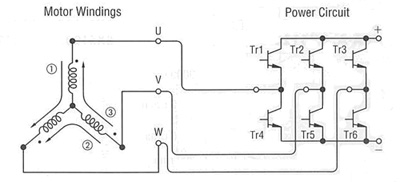

- V / f control or frequency control.

- Changing the number of stator poles.

- Controlling supply voltage.

- Adding rheostat in the stator circuit.

Contents

How can we reduce RPM of motor?

The load to be driven by the shaft will often require a different speed or torque or will require the transmission of power to an adjacent shaft. Reducing RPM can be accomplished by using two or more pulleys and belts to transmit and change the speed of rotation.

How can I reduce motor speed without VFD?

Get a pump driven by a universal motor, (electric tools type, with brushes) and you’ll be able to use voltage variation to get variable speed. Or get a DC driven pump (as used in small ships) and you can also use this cheap electrical variable speed method.

Can we change RPM of motor?

Yes it is possible but not necessarily adviceable. You gave a bit limited information, so I am not sure of your application. Assume it was an induction machine, designed for 50 Hz and 1400 rpm. (Often speed of these machines are 1450 rpm for nominal power).

How do pulleys reduce RPM of motors?

To Decrease RPM, choose Initial Bottom pulley and work up. To Increase RPM select Initial Top pulley and work down. Drag the Rotate slider to animate the diagram and see the actual RPM reduction through all the pulley sets. To Decrease RPM, choose Initial Bottom pulley and work up.

Can you put a rheostat on any motor?

If using a rheostat for motor control it is essential to understand that all types of direct current motors could be speed-controlled, however, a small amount of AC motors are controllable with rheostats.

Can I use a potentiometer to control AC motor speed?

If you mean that you want to control the speed of an AC fan with a potentiometer, it is probably not possible. Whether an AC “mains” fan can be speed controlled with a pot depends on the technology used. Single phase induction motor – capacitor start usually.

What are 3 types of motor controls?

There are four basic motor controller and drive types: AC, DC, servo, and stepper, each having an input power type modified to the desired output function to match with an application.

Can be used to control the speed of 3-phase induction motor?

Speed Control Of Three Phase Induction Motor By Employing Modified Sepic Converter. This project is used to control the speed of the three phase induction motor by employing Modified SEPIC converter. The Modified SEPIC converter is convert the low voltage dc into high voltage dc.

How can the speed of induction motor be controlled?

(2) that the speed of the induction motor can be changed by varying the frequency (f), number of poles (P) or slip (s).

Which of the method can be used for speed control of induction motor?

[Solved] Rheostat method of speed control of induction motor is used.

Can a 60hz motor run on 50hz?

For a generic answer: yes you can, IF: you reduce the voltage by 50/60, the equipment doesn’t care, you don’t care about potentially overheating the motor, the process/load can tolerate the lower speed/torque, etc.

Can I run a 50hz motor at 100 Hz?

Yes, the motor speed increases. I am assuming that it is an induction motor. Speed of the induction motor is proportional to the frequency. So if the frequency is increased to 100 Hz, speed will increase to twice the speed at 50 Hz.

How they could affect the speed of the motor?

- Voltage of Power Supply.

- Type of Power Supply.

- Winding Specifications.

- Environmental Temperature.

- Type of Magnet.

- Flux Yoke.

- Phase.

Can you run an inverter duty motor without a VFD?

General-purpose motors don’t have to use a VFD though, they can be run directly off AC power, with power coming at a very clean and consistent sine wave at 60hz. This creates a steady flow of power with relatively few voltage peaks and little line noise as well.

What controls the speed of a DC motor?

Thus, the speed of a DC motor can control in three ways: By varying the flux, and by varying the current through field winding. By varying the armature voltage, and the armature resistance. Through the supply voltage.

How slow can you run an electric motor?

Following on Long Wang answer, according to Chandrashekhar Dharankar information the motor is rated for 1430 rpm at 60 Hz, so 3 rpm means 0.126 Hz electrical frequency, and some speed ripple could arise. practically, below 10 Hz (50 Hz motor) motor cannot start with full load when using V/F method.

How much speed can reduce by VFD?

VFDs can reduce inrush currents and thus starting torque by 30-75% compared to across-the-line starters. This reduces wear on belts, gears, chains, clutches, shafts and bearings. If high speed must be maintained with a lightly loaded motor, many VFDs can make use of built-in configurable voltage/hertz curves.

How to Reduce RPMs Using Belts & Pulleys | Sciencing

- Article author: sciencing.com

- Reviews from users: 17133

Ratings

- Top rated: 4.8

- Lowest rated: 1

- Summary of article content: Articles about How to Reduce RPMs Using Belts & Pulleys | Sciencing Updating …

- Most searched keywords: Whether you are looking for How to Reduce RPMs Using Belts & Pulleys | Sciencing Updating The operation of shafts driven by electric or internal combustion motors or other forms of power is characterized by speed, torque and the location of the shaft. The load to be driven by the shaft will often require a different speed or torque or will require the transmission of power to an adjacent shaft. Reducing …

- Table of Contents:

How to Calculate a Belt Conveyor

How to Calculate the Speed of Two Different Pulleys

How to Find Belt and Pulley Speeds

How to Convert RPM to Feet per Minute

How to Use a Treadmill Motor for a Wind Generator

How to Calculate Horsepower & RPM

Alternative way to vary pump volume flow without VFD

- Article author: www.vfds.org

- Reviews from users: 26546

Ratings

- Top rated: 4.1

- Lowest rated: 1

- Summary of article content: Articles about

Alternative way to vary pump volume flow without VFD

Updating … - Most searched keywords: Whether you are looking for

Alternative way to vary pump volume flow without VFD

Updating - Table of Contents:

Speed control of three phase induction motor – YouTube

- Article author: www.youtube.com

- Reviews from users: 36583

Ratings

- Top rated: 4.5

- Lowest rated: 1

- Summary of article content: Articles about Speed control of three phase induction motor – YouTube Updating …

- Most searched keywords: Whether you are looking for Speed control of three phase induction motor – YouTube Updating Speed control of three phase induction motorVisit : https://ask-public.com/choose-qa.htmlHomework Help, Speed control of three phase induction motor

- Table of Contents:

Error 403 (Forbidden)

- Article author: www.quora.com

- Reviews from users: 17273

Ratings

- Top rated: 4.6

- Lowest rated: 1

- Summary of article content: Articles about Error 403 (Forbidden) Firstly The speed of motor can be changed on both ses rotor se and stator se .We can reduce the rpm of a 3 phase motor on stair se by controlling … …

- Most searched keywords: Whether you are looking for Error 403 (Forbidden) Firstly The speed of motor can be changed on both ses rotor se and stator se .We can reduce the rpm of a 3 phase motor on stair se by controlling …

- Table of Contents:

circuit analysis – Changing motor RPM – Electrical Engineering Stack Exchange

- Article author: electronics.stackexchange.com

- Reviews from users: 8844

Ratings

- Top rated: 3.4

- Lowest rated: 1

- Summary of article content: Articles about circuit analysis – Changing motor RPM – Electrical Engineering Stack Exchange If it is a 3-phase motor, you can buy a variable frequency drive (VFD), an electronic motor control product. I doubt that is a 3-phase motor … …

- Most searched keywords: Whether you are looking for circuit analysis – Changing motor RPM – Electrical Engineering Stack Exchange If it is a 3-phase motor, you can buy a variable frequency drive (VFD), an electronic motor control product. I doubt that is a 3-phase motor …

- Table of Contents:

3 Answers

3

Your Answer

Not the answer you’re looking for Browse other questions tagged circuit-analysis motor circuit-design motor-controller or ask your own question

Speed Control of Induction Motor – your electrical guide

- Article author: www.yourelectricalguide.com

- Reviews from users: 5247

Ratings

- Top rated: 4.3

- Lowest rated: 1

- Summary of article content: Articles about Speed Control of Induction Motor – your electrical guide The speed of a three phase induction motor is given by, · In this induction motor speed control method, only stator voltage is varied to vary the speed of the … …

- Most searched keywords: Whether you are looking for Speed Control of Induction Motor – your electrical guide The speed of a three phase induction motor is given by, · In this induction motor speed control method, only stator voltage is varied to vary the speed of the … Speed control of 3 phase induction motor, speed control of induction motor, induction motor speed control, speed control of three phase induction motor.

- Table of Contents:

Speed Control of Induction Motor by Stator voltage

Induction Motor Speed Control by Stator Poles

Speed Control of Induction Motor by Rotor Resistance

Speed Control of Induction Motor by Cascade Method

Three Phase Induction Motor All Posts

SEARCH THIS BLOG

CATEGORIES

CONTACT US

QUICK LINKS

Speed Control Methods of Various Types of Speed Control Motors

- Article author: www.orientalmotor.com

- Reviews from users: 35697

Ratings

- Top rated: 3.5

- Lowest rated: 1

- Summary of article content: Articles about Speed Control Methods of Various Types of Speed Control Motors The inverter unit controls the speed of a three-phase induction motor by changing the frequency, f, of the voltage applied to the motor. The inverter unit … …

- Most searched keywords: Whether you are looking for Speed Control Methods of Various Types of Speed Control Motors The inverter unit controls the speed of a three-phase induction motor by changing the frequency, f, of the voltage applied to the motor. The inverter unit … A large number of motors are being used for general purposes in our surroundings from house-hold equipment to machine tools in industrial facilities. The electric motor is now a necessary and indispensable source of power in many industries. The function and the performance required for these motors are wide-ranging.speed control motors, speed control ac motors, speed control electric motors, brushless dc motors, bldc motors, speed control brushless dc motors, dc gear motor speed control

- Table of Contents:

1 Introduction

2 Speed control methods of the various speed control motors

See more articles in the same category here: https://chewathai27.com/toplist.

How to Reduce RPMs Using Belts & Pulleys

The operation of shafts driven by electric or internal combustion motors or other forms of power is characterized by speed, torque and the location of the shaft. The load to be driven by the shaft will often require a different speed or torque or will require the transmission of power to an adjacent shaft. Reducing RPM can be accomplished by using two or more pulleys and belts to transmit and change the speed of rotation.

Measure and note the key characteristics of the system. To design a pulley system to reduce the RPM of the power shaft, you will need the shaft speed, the diameter of the shaft, the distance of the power-shaft-center to load-shaft-center, the load shaft diameter and the required speed of the load shaft. If neither the power shaft nor the load shaft can be moved, you will need a tensioner pulley to keep the belt at the proper tension.

Calculate the sizes of the pulleys. Get the speed ratio by dividing the speed in RPM of the power shaft by the speed in RPM of the load shaft. Assume a power shaft pulley size of 4 inches. This is generally a good size for efficient belt operation. Multiply by the speed ratio. The result will give the load shaft pulley size. A result less than twelve inches is acceptable. Otherwise, reduce the power shaft pulley size to 3 inches and repeat the calculation. Ideally, the power shaft pulley should be 3 inches or more and the load shaft pulley less than 12 inches. Other sizes are possible but a very small pulley on the power shaft is inefficient and causes higher wear due to the greater forces on a smaller diameter. A pulley larger than 12 inches is awkward to install but preferable to having a small pulley on the power shaft.

Purchase and install the pulleys and the belt. If the speed of the load shaft is critical, purchase an adjustable pulley which is made from two halves, bolted together, and this will serve for the power shaft. When the bolts are tightened, the two halves are moved closer together and the effective diameter of the pulley is increased so that the speed can be adjusted slightly.

Make sure the pulleys are designed for the measured shaft diameters and then fix them on their respective shafts. Most shafts have a flat spot and the pulley can be fixed to the shaft by tightening a bolt so that the bolt sits on the flat spot.

Find the length of the belt. Calculate the circumference of each pulley by multiplying the diameter by 3.14. Add half of the diameter of each pulley to twice the shaft-center-to-shaft-center distance. Get the next larger standard size of belt.

Alternative way to vary pump volume flow without VFD

Alternative way to vary pump volume flow without VFD

Case:I have a multistage centrifugal pump in a test rig, and I need change the volume flow very often, although it does not to be accurate. I used to have a variable frequency drive (VFD), and can vary the flow rate very accurately. But the VFD made lots of troubles in the past, noise to the SCADA system, damage in transportation. So I am searching for a rough, simple alternative ways to change the volume. The globe valve option has been considered, but I am still looking for other alternative ways?The motor is fixed, otherwise I can use 4, 6 pole motor to change the speed. One question in my mind is if I can achieve some percentage of volume variation by introducing a variac. My electrical knowledge is limited, I know that if the voltage drop too much the motor can be damaged by the big current. But if the voltage drop is within 10%, the motor can survive, the volume will drop a little bit?Solution:To attempt varying the motor speed through less voltage (for an asynchronous motor) requires a very oversized motor placed in the same hydraulic conditions of the smaller, this means the same pump, but with 3 times the motor power. This is how speeds are changed in domestic roof ventilation fans. Big motors, little power required.Get a pump driven by a universal motor, (electric tools type, with brushes) and you’ll be able to use voltage variation to get variable speed.Or get a DC driven pump (as used in small ships) and you can also use this cheap electrical variable speed method.Variable speed for asynchronous motors is a complicated task for electronics, you have to vary the frequency.The idea to have a multiple speed motor is not bad at all. You can get a skilled repair center to make a 2 pole-4pole-6 pole arrangement in a single housing. Not as easy to make as to say, but not impossible. Will also require a bigger motor. You can also use different sizes of pulley and belt arrangement to change the speed of the pump and hence the flow rate.

Changing motor RPM

\$\begingroup\$

If it is a 3-phase motor, you can buy a variable frequency drive (VFD), an electronic motor control product. I doubt that is a 3-phase motor because 2800 RPM is a bit low to be a standard speed. For good 3-phase, a standard speed would be about 2850 to 2870 RPM.

You could also get a new motor. Something close to 1400 RPM, say 1450 to 1470 RPM would be a standard speed for a 50 H, 3-phase motor. A standard speed for a single-phase motor would be closer to 1400 RPM.

You might be able to find a VFD for a single-phase motor, but it would be rather expensive and difficult to find. Whether the VFD would good performance or even work at all would depend on the specific type of single-phase motor and the load characteristics.

If 3-phase power is available, it would be best to buy a 3-phase, 1400 RPM motor. If only single-phase power is available, then buy a single-phase 1400 RPM motor. If you don’t need variable speed, there is little or no possible advantage in using a VFD to change the frequency unless you have a motor that would be very difficult to replace. There are some disadvantages.

Keep in mind that power is torque multiplied by speed. A 3 Hp, 1400-RPM motor will have twice as much torque as a 3-Hp, 2800-RPM motor. If you are going to buy both a motor and a VFD, it is best to carefully consider what is required for each, consider what is required for them to work together then buy both. In this case, it seems highly likely that the best solution is to buy a suitable motor that can do the job without a VFD. If you have access to a local seller that you trust to provide good advice and support, buy from that seller. If you decide that you need both a VFD and a motor, buy both from the same trusted seller.

So you have finished reading the how to reduce rpm of 3 phase motor topic article, if you find this article useful, please share it. Thank you very much. See more: 3 phase motor speed controller, speed control of 3-phase induction motor pdf, induction motor speed, 3 phase induction motor speed formula, voltage frequency control of induction motor, speed control of ac motor pdf, low speed 3 phase motor, Three-phase motor