You are looking for information, articles, knowledge about the topic nail salons open on sunday near me how to mark 45 degree angle on pipe on Google, you do not find the information you need! Here are the best content compiled and compiled by the https://chewathai27.com team, along with other related topics such as: how to mark 45 degree angle on pipe 45 degree angle pipe fitting, how to cut square pipe 45 degree angle, how to cut a 22.5 degree angle on pipe, how to cut 30 degree angle on pipe, 45 degree angle pipe template, how to cut a 90 degree angle on pipe, pipe angle cutting template, pipe angle tool

Contents

What is the formula of miter elbow?

calculate the total length of the bend using the formula, l=r x theta, where r=radius of the center line of the bend and theta = bend angle in radians.

How do you draw a 45 degree angle without a protractor or compass?

- Draw a line segment BC of any length.

- Taking B as the center, construct a semicircle that bisects BC at point P.

- From P, construct three arcs dividing the semi-circle into 3 equal parts that are 60º each.

- Mark the points as x and y where the arcs bisect the semi-circle.

How to Cut Pipe Angles Accurately – Kevin Caron – YouTube

- Article author: www.youtube.com

- Reviews from users: 26768

Ratings

- Top rated: 4.5

- Lowest rated: 1

- Summary of article content: Articles about How to Cut Pipe Angles Accurately – Kevin Caron – YouTube Updating …

- Most searched keywords: Whether you are looking for How to Cut Pipe Angles Accurately – Kevin Caron – YouTube Updating #FabricationTips #KevinCaronArtFrom http://www.kevincaron.com – Artist Kevin Caron explains how to cut angles on pipe at the correct angle ….Kevin Caron ha…artist, fabricated steel, sculptor Kevin Caron, artist Kevin Caron, sculpture artist Kevin Caron, how-to videos, how to videos, free videos, tools, machines, cut metal, cut metal pipe, cutting metal, cutting metal pipe, band saw, hack saw, chop saw, metal cutting, pipe cutting, without metal cutting tools, cut accurate pipe angles

- Table of Contents:

Home Remodeling Tips : How to Set an Angle with a Speed Square – YouTube

- Article author: www.youtube.com

- Reviews from users: 28235

Ratings

- Top rated: 3.9

- Lowest rated: 1

- Summary of article content: Articles about Home Remodeling Tips : How to Set an Angle with a Speed Square – YouTube Updating …

- Most searched keywords: Whether you are looking for Home Remodeling Tips : How to Set an Angle with a Speed Square – YouTube Updating In addition to the 90-degree and 45-degree angles so simple to scribe from an angle, you can also use a speed square to set any other angle between zero degr…home help tips, home remodeling tips, remodeling techniques, home remodeling tools, woodworking equipment, mortises, working with copper pipe, table saw techniques, home improvement tips, home improvement tech

- Table of Contents:

How to Cut Pipe at an Angle Accurately – Kevin Caron – YouTube

- Article author: www.youtube.com

- Reviews from users: 17080

Ratings

- Top rated: 3.2

- Lowest rated: 1

- Summary of article content: Articles about How to Cut Pipe at an Angle Accurately – Kevin Caron – YouTube Updating …

- Most searched keywords: Whether you are looking for How to Cut Pipe at an Angle Accurately – Kevin Caron – YouTube Updating From http://www.kevincaron.com – Sculptor Kevin Caron shows how how to cut pipes at an angle for joining without having fancy tools….A viewer, Dave, wrote …artist, art, fabricated steel, sculptor Kevin Caron, artist Kevin Caron, sculpture artist Kevin Caron, how-to videos, how to videos, free videos, join pipe, pipefit, pipefitting, fit pipe, fit pipe without tools, hole saw, band saw, chp saw, tools, machines, benchgrinder, wirewheel

- Table of Contents:

Making a Template to Miter Pipe – YouTube

- Article author: www.youtube.com

- Reviews from users: 34485

Ratings

- Top rated: 4.2

- Lowest rated: 1

- Summary of article content: Articles about Making a Template to Miter Pipe – YouTube Updating …

- Most searched keywords: Whether you are looking for Making a Template to Miter Pipe – YouTube Updating Make a template to layout Pipe, Round Tubing or Sheet Metal.Dave shows how to use “line development” on graph paper to make a template to miter round pipe or…Pipe template, Cutting miters on pipe, Pipe layout, Miter Joint

- Table of Contents:

how do I layout an angle cut on large diameter pipe?

- Article author: weldingweb.com

- Reviews from users: 28750

Ratings

- Top rated: 4.0

- Lowest rated: 1

- Summary of article content: Articles about how do I layout an angle cut on large diameter pipe? For a 45 degree angle just do some math to find the difference between the low se and the high se of the angle. Mark them on their respective ses. …

- Most searched keywords: Whether you are looking for how do I layout an angle cut on large diameter pipe? For a 45 degree angle just do some math to find the difference between the low se and the high se of the angle. Mark them on their respective ses. pipe, layout, makes, wizard, compass, flange, marking, handy, angle, large, diameter, mentionedWhat is the best way to layout a cut line on large diameter pipe for, let’s say, a 45 degree cut?

I needed to cut a piece of 12″ pipe with a grinder/cut off wheel the other day since we don’t have a band saw that big. I laid out a line that I thought was right. After I made my cut and rotated my parts for my 45 degree elbow I was making. I ended up with a lot of grinding to make the pieces fit good enough to weld.

Any help here?

- Table of Contents:

how do I layout an angle cut on large diameter pipe

Re how do I layout an angle cut on large diameter pipe

Re how do I layout an angle cut on large diameter pipe

Re how do I layout an angle cut on large diameter pipe

Re how do I layout an angle cut on large diameter pipe

Re how do I layout an angle cut on large diameter pipe

Re how do I layout an angle cut on large diameter pipe

Re how do I layout an angle cut on large diameter pipe

Re how do I layout an angle cut on large diameter pipe

Re how do I layout an angle cut on large diameter pipe

Re how do I layout an angle cut on large diameter pipe

Re how do I layout an angle cut on large diameter pipe

how do I layout an angle cut on large diameter pipe?

- Article author: mathcentral.uregina.ca

- Reviews from users: 1349

Ratings

- Top rated: 3.3

- Lowest rated: 1

- Summary of article content: Articles about how do I layout an angle cut on large diameter pipe? Hi Bakshani. Two ways come to mind: an easy way and a more “mathematical” way: Easy way: Submerge the end of the pipe in water at a 45 degree angle. Use a … …

- Most searched keywords: Whether you are looking for how do I layout an angle cut on large diameter pipe? Hi Bakshani. Two ways come to mind: an easy way and a more “mathematical” way: Easy way: Submerge the end of the pipe in water at a 45 degree angle. Use a … pipe, layout, makes, wizard, compass, flange, marking, handy, angle, large, diameter, mentionedWhat is the best way to layout a cut line on large diameter pipe for, let’s say, a 45 degree cut?

I needed to cut a piece of 12″ pipe with a grinder/cut off wheel the other day since we don’t have a band saw that big. I laid out a line that I thought was right. After I made my cut and rotated my parts for my 45 degree elbow I was making. I ended up with a lot of grinding to make the pieces fit good enough to weld.

Any help here?

- Table of Contents:

how do I layout an angle cut on large diameter pipe

Re how do I layout an angle cut on large diameter pipe

Re how do I layout an angle cut on large diameter pipe

Re how do I layout an angle cut on large diameter pipe

Re how do I layout an angle cut on large diameter pipe

Re how do I layout an angle cut on large diameter pipe

Re how do I layout an angle cut on large diameter pipe

Re how do I layout an angle cut on large diameter pipe

Re how do I layout an angle cut on large diameter pipe

Re how do I layout an angle cut on large diameter pipe

Re how do I layout an angle cut on large diameter pipe

Re how do I layout an angle cut on large diameter pipe

how do I layout an angle cut on large diameter pipe?

- Article author: xn--gi-h-rqa8b.vn

- Reviews from users: 23310

Ratings

- Top rated: 3.9

- Lowest rated: 1

- Summary of article content: Articles about how do I layout an angle cut on large diameter pipe? Top 11 ✓ How to mark 45 degree angle on pipe được cập nhật mới nhất lúc 2022-03-05 01:18:10 cùng với các chủ đề liên quan khác , how to mark 45 degree … …

- Most searched keywords: Whether you are looking for how do I layout an angle cut on large diameter pipe? Top 11 ✓ How to mark 45 degree angle on pipe được cập nhật mới nhất lúc 2022-03-05 01:18:10 cùng với các chủ đề liên quan khác , how to mark 45 degree … pipe, layout, makes, wizard, compass, flange, marking, handy, angle, large, diameter, mentionedWhat is the best way to layout a cut line on large diameter pipe for, let’s say, a 45 degree cut?

I needed to cut a piece of 12″ pipe with a grinder/cut off wheel the other day since we don’t have a band saw that big. I laid out a line that I thought was right. After I made my cut and rotated my parts for my 45 degree elbow I was making. I ended up with a lot of grinding to make the pieces fit good enough to weld.

Any help here?

- Table of Contents:

how do I layout an angle cut on large diameter pipe

Re how do I layout an angle cut on large diameter pipe

Re how do I layout an angle cut on large diameter pipe

Re how do I layout an angle cut on large diameter pipe

Re how do I layout an angle cut on large diameter pipe

Re how do I layout an angle cut on large diameter pipe

Re how do I layout an angle cut on large diameter pipe

Re how do I layout an angle cut on large diameter pipe

Re how do I layout an angle cut on large diameter pipe

Re how do I layout an angle cut on large diameter pipe

Re how do I layout an angle cut on large diameter pipe

Re how do I layout an angle cut on large diameter pipe

Pipe cutting at an angle: an overview of the best ways and tricks

- Article author: engineer.decorexpro.com

- Reviews from users: 16183

Ratings

- Top rated: 3.8

- Lowest rated: 1

- Summary of article content: Articles about Pipe cutting at an angle: an overview of the best ways and tricks The simplest way to get a marking line on a pipe to produce a cut at an angle of 45 degrees. A plain sheet of paper is used that is applied to the pipe body … …

- Most searched keywords: Whether you are looking for Pipe cutting at an angle: an overview of the best ways and tricks The simplest way to get a marking line on a pipe to produce a cut at an angle of 45 degrees. A plain sheet of paper is used that is applied to the pipe body … What methods of cutting pipes at an angle are used in practice, their advantages and disadvantages. Examples of using mechanical and hardware cutting methods

- Table of Contents:

Pipe cutting techniques at an angle

Precision Cutting Machines

Industrial models (for example BSM)

The use of thermal methods

Conclusions and useful video on the topic

How To Cut Pipe At 45 Degrees Angle Grinder • CIMFLOK.COM

- Article author: cimflok.com

- Reviews from users: 22515

Ratings

- Top rated: 4.0

- Lowest rated: 1

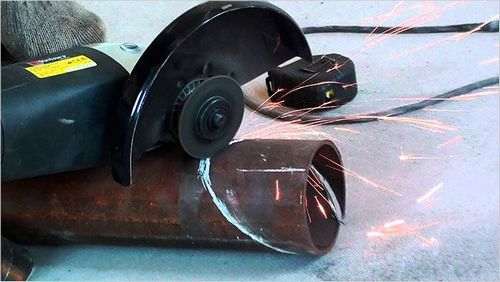

- Summary of article content: Articles about How To Cut Pipe At 45 Degrees Angle Grinder • CIMFLOK.COM Place a piece of wood for support. Run your angle grinder around the circumference of the pipe making small cuts. Then take the … …

- Most searched keywords: Whether you are looking for How To Cut Pipe At 45 Degrees Angle Grinder • CIMFLOK.COM Place a piece of wood for support. Run your angle grinder around the circumference of the pipe making small cuts. Then take the … How to cut pipe at 45 degrees angle grinder How to cut pipe at 45 and 90 degrees. Cutting Methods Angle Grinder Large Diameter and Thin-Wall Tubes How to

- Table of Contents:

How to cut a pipe straight with an angle grinder

Pipe cutting at an angle of 45 and 90 degrees

How to properly cut a pipe at 45 degrees tools

Pipe marking and cutting

Circular pipe marking and cutting

Computer program to help

How to cut a pipe at 45 degrees

Layout by means of a sheet of paper

Post navigation

Kimberlyblog-Stephenson

- Article author: kimberlyblog-stephenson.blogspot.com

- Reviews from users: 36147

Ratings

- Top rated: 4.1

- Lowest rated: 1

- Summary of article content: Articles about Kimberlyblog-Stephenson So lets take a look at a schematic that I drew earlier that represents a pipe being off-setted at a 45 angle to get passed a hot water tank … …

- Most searched keywords: Whether you are looking for Kimberlyblog-Stephenson So lets take a look at a schematic that I drew earlier that represents a pipe being off-setted at a 45 angle to get passed a hot water tank …

- Table of Contents:

Apa Maksud Hukama

Words to Describe a Good Sermon

Ayat Bio Untuk Instagram

Cara Nak Buat Bisnes Baju Online

Archive

Author Description

See more articles in the same category here: 670+ tips for you.

Pipe cutting at an angle: an overview of the best ways and tricks

Pipes are a widespread building material. They are used in the installation of various systems. During installation, situations happen when pipes need to be joined at an angle. The production technology of such works is not standard, but you need to know about it.

To create a complex joint configuration, pipe cutting at an angle is required. We will describe how such operations are performed and what cutting methods exist.

Pipe cutting techniques at an angle

Considering the methods of work – cutting directly or at an angle – it is necessary to take into account the different material of the products subjected to processing. So, hoses made of polypropylene or thin copper are easier and easier to cut than thick-walled steel pipes.

Plastic products of small diameters are cut at the right angle with . In this case, you can control the angle with a conventional protractor. Cutting of polymer pipes is also performed by a conventional hacksaw with a fine-toothed blade.

The most frequent installation need is cutting water, sewer and ventilation pipes at an angle of 45º.

Find out what devices can be used for cutting at different angles.

Paper pattern for pipe

For the execution of a relatively accurate cut, you can apply a simple technique, where an ordinary sheet of paper acts as a kind of pattern. For example, it is suitable for creating patterns of A4 printer paper.

Previously, the sheet is marked out under a square using a ruler. The diagonal size of the square should be equal to the circumference of the pipe to be cut. Excess parts of the sheet are cut off.

Next, the following steps:

Bend the sheet diagonally, aligning opposite corners. Rotate the resulting triangle so that the hypotenuse line is perpendicular to the axis of the pipe. In this position, wrap the pipe surface with paper, aligning the extreme points of the hypotenuse together. Mark with a marker the cut mark along the line of any of the legs of the triangle. Trim the pipe along the intended line.

In this way, it is quite convenient to mark and cut pipes at an angle of 45º in the range of diameters from 32 to 63 mm. For greater convenience, it is recommended that you take thick but soft paper. You can also use paronite and similar materials.

How to choose wisely and how to apply it in practice is described in detail in our article.

Properly made patterns for figured pipe cutting allow you to cut sections with extremely high accuracy. At the same time, a gap between the prepared workpieces is still possible. In the connection of metal pipes, it is “closed” with a weld seam, when connecting plastic parts, a specialized soldering cord is used.

Programs for calculating cutting angles

Cutting technology for patterns allows you to get different cutting angles. But for the formation of a pattern at angles other than 45º, it will already be necessary to perform mathematical calculations and, based on the calculated data, cut out a template from paper or similar materials.

True, there are computer programs designed to save the wizard from the production of calculations.Patterns for pipe cutting such programs are printed on a printer.

A simple calculation program, created on the basis of MS Excel, allows you to calculate and compose a pattern for almost any value of pipe diameters and the required cutting angles.

All that the user needs to do is enter the corresponding values in the “Outer Diameter” and “Cutting Angle” cells. According to these parameters, a pattern will be formed that can be sent for printing.

Pipe cutting miter box

There is a simple tool, often used in everyday life, mainly for working with wood. It is called – a miter box. So, this same device is suitable for cutting pipes, and at different angles.

The miter box is on sale, but if you want, you can always do it yourself and adjust the design to the desired pipe diameter:

Take a wooden board with a width equal to the diameter of the pipe, 400-500 mm long. Take two more boards of the same size, but in width increased by the thickness of the first board. From three boards to assemble the design in the form of an inverted letter “P”, where the first board is installed as the base. In the central part of the structure, mark a rectangle, the two sides of which pass along the inner borders of the side boards. Divide the rectangle with diagonals and along the lines obtained on the upper faces of the side boards, make cuts down to the base.

In this way a template is made for cutting at an angle of 45º. But with the help of a protractor, you can mark almost any angle and make cuts under the pipe cut for a specific angle.

The advantage of the miter box – the tool is suitable for repeated use. Work with the tool is permissible to such a degree of wear of the walls of the slots, while they can provide high precision cutting. It is recommended that the tool walls be made of a material of higher strength than wood.

The advantages of the method are obvious – simplicity, ease of manufacture of the tool (miter box), efficiency, versatility. The disadvantages of working with such a snap option are the need to adjust the size of the miter box to the pipe diameter, provided that an accurate cut is made. That is, for each pipe you have to make your own tool.

Also, with the help of a miter box, you can cut a pipe only with a hacksaw for metal or a secateurs (for plastic products). For working with thick-walled metal pipes under a cut grinder, this tool will not work.

Simple cutting equipment

Metal products of round and rectangular shapes, having sufficiently thick walls, are conveniently cut at an angle using straightforward electromechanical equipment.

The cutting element of such a tool is a cutting disc or circular saw mounted on an electric motor shaft. In turn, the electric motor with a torch is part of the entire equipment, which includes the desktop, pendulum support, clamp.

To install the pipe at the desired angle and then fasten it, an ordinary clamp and two metal corners are used.One corner (short) is attached to the base of the swing mechanism – the pendulum. The second corner (long) is in a free state.

Pipe laying and cutting procedure:

The rotary mechanism sets the desired cutting angle (for example, using a ruler and protractor). The found position is fixed by clamping screws. Between the short and long corners, a pipe is laid and pressed against the clamp screw. A voltage is applied to the electric motor. Applying a slight pressure force to the torch disc, the pipe is cut in the right place.

The advantages of this technique are fast work, accurate cut, the ability to process a large number of pipes in a short period of time.

Disadvantages: restrictions on use in domestic conditions, increased noise, work with pipes of only small and medium diameters. In addition, the snap cutting process is carried out stationary at a distance from the installation site, which is not always acceptable.

If you are going to make a copper pipe at home, then you will need , the selection rules of which we advise you to read.

The nuances of working with a rectangular section

To perform cutting of rectangular products, it is recommended to prepare template cuts of corners in advance. They are easy to make from a metal corner, previously marking with the same protractor.

Marking can be done for different angles. To use the template in the case, it is enough to attach it to a rectangular pipe in the right place and mark the cut line. Then, with any suitable tool, cut along the intended line.

Precision Cutting Machines

Among the branded devices that could be used in everyday life for cutting at an angle, you can pay attention to Italian-made technology.

The MASS Mini Cut Band Saw is a small-sized device with a manual clamp, for working not only with pipes, but also with corners, rods, and profile elements.

The machine supports setting the cutting angle from 0 to 45º. The procedure is carried out using a tape web at a speed of 45 reciprocating movements per minute. The device is equipped with an electric motor with a power of 370 W, which is powered by a household network. The maximum allowable diameter of the cut round pipe is 65 mm.

Numerous installations with electromechanical and electric drives have been developed on an industrial scale for pipe cutting. Technically sophisticated machines allow for high precision thermal, oxygen and plasma cutting:

Industrial models (for example, BSM)

There are special industrial machines for precise angle cutting operations. A good example: devices manufactured under the brand name “BSM”. The machine manufacturer is the German company Rexinger.

True, the BSM series machines are designed exclusively for working with polypropylene pipes of sufficiently large diameters. Processing of products like PP, PVC, PE, PVDF is supported.

The cutting tool of the machine is a band saw, due to which the cut is performed at angles from 0 to 67.5º. The precision of the process is provided by a laser cutting recognition.

Despite the configuration of the device for large diameters, you can use a special table with which pipes of small diameters (50 – 200 mm) are also successfully cut, which are easier to cut with . A wide range of BSM devices is available.

The use of thermal methods

In addition to mechanical methods, thermal methods are often used, where welding or cutting machines work as tools. For example, an autogenous gas cutter or a conventional welding machine (direct / alternating current).

Using such cutting machines, thick-walled metal pipes are available. However, it is extremely difficult to obtain a perfectly even high-quality cut using the electric welding or gas autogen method.

Electric and autogenous cutting technology is ubiquitous. The technique does not provide high precision cutting, but when installing pipes this factor is often not determining

Usually, after thermal cutting, the products are subjected to additional processing. The cut line is aligned, the values of the required angle are adjusted. This approach is economically disadvantageous, as it is accompanied by additional costs for machining.

As a rule, the thermal cutting technique is applied in the conditions of the industrial-production sphere. True utility services also often resort to such a technique.

Thermal cutting is also used for working with plastic material. There are devices – thermal guillotines. The sharp thin blade of such devices is heated to a high temperature, and then perform a cut.

Thermal guillotines support cutting at an angle, and this is their advantage. However, to work with tougher materials than polyvinyl chloride, wood, chipboards, these devices cannot be used.

For cutting able to evenly divide into parts of the product with a multilayer structure. The article recommended by us is devoted to their varieties and methods of application.

Conclusions and useful video on the topic

The video shows the calculations and shows a workshop on how to cut pipes at angles of 45º and 90º:

For each individual installation case, you can choose the most convenient and less expensive method of cutting. The specific choice depends on the material of the pipe, its diameter, wall thickness.

Using simple marking methods, you can get a fairly accurate angle at which you want to cut the workpiece. At the same time, turning to a complex calculation procedure, it is possible to cut at non-standard angles with high accuracy.

Do you have useful information on the topic of the article? Do you have questions in the process of familiarization with the material or found controversial issues? Please write comments in the block below.

How To Cut Pipe At 45 Degrees Angle Grinder • CIMFLOK.COM

How to cut pipe at 45 degrees angle grinder How to cut pipe at 45 and 90 degrees. Cutting Methods Angle Grinder Large Diameter and Thin-Wall Tubes

How to cut a pipe straight with an angle grinder?

When dealing with construction or plumbing tasks, you need to know how to cut the pipe straight from an angle grinder. In the article, we will consider quick and easy ways to properly cut an angle grinder pipe so that the result is perfect.

Pipe cutting at an angle of 45 and 90 degrees

If you need to cut the pipe at an angle of 45 degrees, which is more often required when laying water and heating pipes. Steel, cast iron pipes that are cylindrical in shape are often used. In the installation work, rectangular or shaped pipes are used. However, the pipe of the angle grinder should be cut correctly so that it can be easily connected later. Therefore, you should carefully mark the pipe.

Some craftsmen try to mark the place of the cut using a tape measure, but we warn you that the result is likely to be negative. And for a positive result, consider the following professional recommendation.

Take a sheet of paper or cardboard, preferably A4, fold it diagonally and wrap it around the pipe where you plan to cut it evenly. The edges of the paper should be exactly aligned with each other. And the side of the paper that is closer to the end of the pipe was perpendicular to the axis. Then mark the cut line in a circle.

If you need to cut exactly at an angle of 90 degrees, then solve the problem quickly using paper or masking tape again. Wrap around the pipe so that the ends match. Make even lines and saw off.

How to cut a profile pipe straight?

Masters advise using a square when cutting a profile pipe. To do this, apply the square in turn to the sides, and turn and mark with smooth movements. After action, fix the pipe and cut. Prepare yourself a template that will come in handy in the future and save time. It is better to produce an angle grinder, so the cut will be smoother.

How to cut a cast iron pipe?

When working with a cast iron pipe, keep in mind that it is a brittle material. Therefore, we will point out a method with which it will be possible to cut such a metal without damage.

Before starting work, make notes for the cut, just like with steel pipes. Place a piece of wood for support. Run your angle grinder around the circumference of the pipe making small cuts. Then take the chisels, insert them into the groove and hit hard with a hammer. Note that bakelite-based cut-off wheels are used to cut cast iron pipes.

If you don’t have an angle grinder on hand to cut a cast-iron sewer pipe or other purposes, use a metal hacksaw, chisels or special pipe cutters.

How to cut a gas pipe?

Cutting a gas pipe is dangerous, so it is best to entrust it to professionals. But if you are confident in your strength, then take an angle grinder, welding, hacksaw, gas welding to cut the metal.

Shut off the gas riser before work. Then release the rest of the gas from the pipe. To do this, light the gas in the burners and wait for it to go out.

After the actions taken, cut. Using the welding method, the metal base burns when exposed to high temperature. The result is fast and effective. But remember that cutting or rooting gas pipes again takes experience.

How to properly cut a pipe at 45 degrees: tools

In various situations, household-level craftsmen often come to the question of the correct marking for accurate cutting of pipe blanks at an angle of 45 degrees. Today, there is a huge selection of tools, both for the domestic and industrial process of cutting pipes at any angle. The cost of such devices can be quite high.

It is proposed to consider methods of marking blanks for cutting at an angle of 45 degrees in a domestic environment without the use of expensive professional equipment.

Pipe marking and cutting

The very process of marking the cut-off workpiece seems to be quite a simple matter. But it should be noted that the roundings made during the manual marking process will create an irreparable error after cutting, which will lead to inconsistencies and the formation of defective products. In order to eliminate such defects, it is required to make a simple tool for a clear marking of the profile parts. This makes cutting products at an angle of 450 much easier.

A regular 45-degree U-shaped steel section is a reliable tool for accurate pipe cutting. In this case, the size of the profile for the ruler must be selected so that it becomes possible to easily position the cut profile pipe in it.

Manual pipe cutting tool

To perform such a tool marking the correct angle, you must also have the following additional tool:

Protractor; Scraper for metal; Angle Grinder; Cutting disc; File.

Pipe bevel cutter

How to cut a pipe at an angle

It is not difficult to make a measuring tool for cutting pipes. To do this, it is necessary to cut a segment with a length of 20-30 cm from the profile blank. By means of a goniometer, at any end of the segment, it will mark an angle of 45 degrees. Next, cut off the profile with the angle grinder. The resulting template needs to be tested for accuracy. In case of deviations, file the measuring tool.

Using such a hand-made marking tool, the process of cutting pipes is much easier, especially with a large volume of pipes. To mark, it is only necessary to place the cut profile pipe in the made device and draw the correct angle with a scribe. During the marking process, the length of the products is controlled. Next, you need to cut the pipe clearly along the line markings using an angle grinder. It is worth noting that at first the pipe is cut along the diagonal marks on both sides, then the straight, marked mowing lines are cut. These 45 degree pipe cutting templates will save you a lot of time and money.

Circular pipe marking and cutting

When cutting round pipes at an angle of 45 degrees, the tool made for rectangular pipes is not quite suitable. For a more accurate streamlined tracing of the mowing line for an angle cut, it is recommended to use a paper template that is wound around the workpiece.

Patterns are developed in the modern world using computer programs.

The cut line changes depending on the angle and pipe diameter set in the program. Common patterns can be found on the Internet or you can remember our painted rulers from the school bench.

Computer program to help

I would also like to consider a way to markup using a computer program. This is an extremely difficult way for those who are not used to working with a computer. It requires knowledge of a PC, the availability of programs for scans and drawings. We start with the execution of the drawing indicating the size of the circle and the slope. We make a so-called virtual template.

After that, using the printer, we print the image on a sheet of paper. The larger the pipe diameter, the more markup pages there will be. We cut out all parts of the drawing with scissors and with the help of tape, glue them. The finished template is applied to the pipe, and we make markings along the edge of the paper. This markup method is considered one of the most correct. If the computer does not have such programs, it is possible to use the Internet. It is possible to download a pattern for marking on the net. It also needs to be printed on a printer and cut out. We wrap the finished piece near the pipe and make markings.

How to cut a pipe at 45 degrees

When installing the pipeline, it is quite often necessary to cut the pipe at an angle. over, the angle should have just the degree that is needed for the structure. If the corner is not made correctly, it is unrealistic to make exactly the dimensions of the pipeline that were supposed to be made. For example, a pipe will rotate 45 degrees during installation, therefore, you need to know how to cut a pipe at 45 degrees. To do this, we need marking tools, an angle grinder or a hacksaw for metal.

Layout by means of a sheet of paper

One of the easiest ways is to mark the corner with a piece of paper. We fold the square sheet strictly diagonally. We take the pipe and wrap it in a folded page so that the edges of the diagonals are opposite each other. So, on the smaller side of the page, we have an angle of 45 degrees. We take any marking tool and mark the place of the future pipe cut along the mowing line of the page. So that the markings are not accidentally erased, it is possible to use narrow tape. This method of marking is convenient for a long pipe of huge diameter, and the cut of which is somewhere in the middle.

This is a collective farm speculative option for those who cannot make the markup by eye as written in the previous paragraph of this very post of mine. This method was spied on by workers who laid a main water pipe with a diameter of 500 or 700 mm under my office windows. The highest accuracy will not be here, but it is enough for welding, with a certain accuracy it is possible to set the cutting plane.

So you have finished reading the how to mark 45 degree angle on pipe topic article, if you find this article useful, please share it. Thank you very much. See more: 45 degree angle pipe fitting, how to cut square pipe 45 degree angle, how to cut a 22.5 degree angle on pipe, how to cut 30 degree angle on pipe, 45 degree angle pipe template, how to cut a 90 degree angle on pipe, pipe angle cutting template, pipe angle tool