Contents

#HACCP Training with example Part 1️⃣ (Orange Juice 🍹🍹🍊🍊) in very simple | ข้อมูลวัฒนธรรมที่ปรับปรุงใหม่.

คุณสามารถค้นหาข้อมูลที่เป็นประโยชน์เพิ่มเติมได้ที่นี่: Chewathai27.com .

#HACCP Training with example Part 1️⃣ (Orange Juice 🍹🍹🍊🍊) in very simple และรูปภาพที่เกี่ยวข้องกับหัวข้อนี้.

ข้อมูลที่เกี่ยวข้องกับหัวข้อ ตัวอย่าง haccp plan.

How to monitor a CCP point in HACCP plan ? HACCP Training with example Part 1️⃣1️⃣

How to monitor an OPRP point in HACCP plan ? HACCP Training with example Part🔟

HACCP Training with example Part 9️⃣ The Main Rules of Flow_Diagrams in very exciting way

HACCP Training with example Part 8️⃣ CCP (Critical Control point) & OPRP process flow detection

Food Quality Control Job Description

Food Quality Assurance Job Description

Food Safety Specialist Job Description

Difference between GWP (Good Warehousing Practices)🏪🚚 & GAP (Good Agricultural Practices)🚜

Difference between GMP (Good Manufacturing Practices)🏭 & GLP (Good Laboratory Practices)🏷️🔬

Hello every body on simplyfoodea channel

Today we will explain the first 5 steps of HACCP

Hazard Analysis and Critical Control Points

The HACCP system was first introduced in the 1960s in NASA to ensure food safety for astronauts.

Application of the HACCP system in addition to the Prerequisite Programs and the Good Manufacturing Practices (GMPs) provides the best protection for food.

The application of the HACCP system ensures that the company controls all the hazards that may affect food, whether these hazard are physical, chemical or biological.

Orange Juice HACCP plan

The 12 Steps To Develop a HACCP Plan are divided to 5 Primary Steps and 7 Basic Principles.

The 5 Primary Steps are :

1 Assemble the HACCP Team.

2 Describe the Product

( components and storage condition ).

3 The Intended Use and Consumers.

4 Draw a Flow Diagram to Describe the Process steps.

5 OnSite Confirmation of Flow Diagram.

1. Assemble the HACCP Team from different departments (Top Management + Quality and Food Safety + Production + Sales + Maintenance + Purchasing).

2 Describe the Product ( components and storage condition ) (Natural Pasteurized Orange Juice) and its components (Orange + Water) specifications (Sugar Free) and methods of preservation (stored in the refrigerator in temperature from 4 8 ⁰) calorie/ml .

3 The Intended Use and Consumers (Drink directly from the bottle / user category age from two years and not recommended for patients with pressure) Validity / Expire period of 14 days.

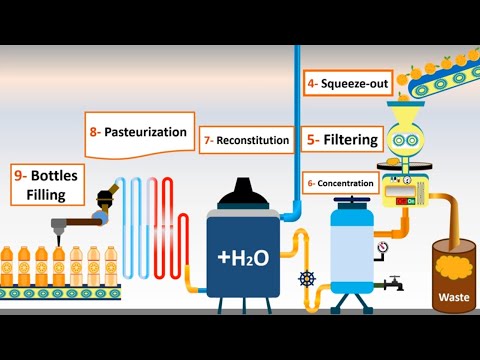

Orange Juice flow diagram steps

1 Receiving of Orange

2 Sorting of Orange

3 Washing

4 Squeezeout

5 Filtering

6 Concentration

7 Reconstitution

8 Pasteurization

9 Bottles Filling

10 Bottles capping

11 X Ray

12 Dating the bottles

13 Packing the bottles

14 Arranging on Pallets

15 Storing

16 Distribution

The 7 principles of HACCP (must memorize in order)

1 Conduct a Hazard Analysis

2 Identify the Critical Control Points

3 Establish Critical Limits

4 Monitor CCPs

5 Establish Corrective Action

6 Verification

7 – Recordkeeping / Documentation

Step 2 Product descriptions –

End products must be characterized by type and description in order to facilitate hazard analysis. Information must include:

1. Product categorization

2. Composition

3. Biological, chemical, and physical characteristics

4. Shelf life and storage conditions

5. Packaging

6. Labelling related to food safety – including handling, preparation and usage instructions

7. Method of distribution

Step 3 Intended Use

1 The end intended use of the products must be described in a manner that defines:

1. Who will consume the products?

2. How is the end product to be consumed?

3. If the end product is mishandled, what is the food safety risk?

Step 4 Process Flow Diagram Construction

1 The flow diagram is a schematic overview of the operation/production process. They may be formed by site, line, product or area but must cover all food operations covered within the HACCP Scope, have sufficient detail to allow for effective hazard analysis, and show clear cross referencing between diagrams where required.

2 Flow diagram content must include the following, where relevant:

• The sequence and interaction of all process steps

• Raw materials, utilities, and food contact material introduction points

• Potential for process delay

• Rework and recycling points

• Outsourced processes and subcontracted work

• Any high/low risk area segregation

• All product forms finished, intermediate/semiprocessed, byproducts, downgraded forms and waste

• CCP’s and their overview

Step 5 Process Flow Diagram Verification

1 Diagrams as developed above must be verified by physically following the process (walk the line) during production to confirm accuracy and completeness.

2 This must be completed by, as a minimum, representatives from the QA, Manufacturing and Engineering functions in the HACCP team

3 This verification must be documented and reconfirmed annually, or when a process is changed.

Food Safety Creating a HACCP Plan

Plan HACCP Análisis de peligros GlobalTV

Since June 2019, the FDA and USDA have been strictly enforcing HACCP compliance for restaurants in the United States. Stay ahead of the curve and educate yourself on what HACCP is and how it will affect your restaurant.

HACCP is a sciencebased management system and an internationally recognized food safety system with process steps that emphasize a proactive approach to food safety and health. HACCP is an acronym that stands for: Hazard Analysis and Critical Control Points. The HACCP system identifies and controls three potential food safety hazards in: Biological, Chemical, and Physical and is all about PREVENTION.

To read about HACCP, check out our article on our blog:

Visit

Or call us at 2133402523

HACCP (hazard analysis and critical control point) is a sciencebased management system and an internationally recognized food safety system with process steps that emphasize a proactive approach to food safety and health. HACCP is an acronym that stands for:

Hazard

Analysis and

Critical

Control

Points

The HACCP system identifies and controls three potential food safety hazards in:

Biological

Chemical

Physical

The United States Food and Drug Administration (FDA) and Department of Agriculture (USDA) both require mandatory HACCP programs for juice, meat, and seafood in an effort to uphold a level of food safety and to maintain and protect public health. The end goal is to have a finished product that has had its safety ensured and documented every step of the way.

There are 7 HACCP principles that make up and define a great HACCP plan. The 7 HACCP principles follows a path from start to finish that begins with building a HACCP team, constructing flow diagrams, identifying hazard control points, critical control points, and their respective limits.

This allows for CCP monitoring or critical control point monitoring. HACCP decision trees are then used to help decide whether a hazard control point is a critical control point or not.

These principles are as follows:

Perform hazard analysis

Define critical control points

Define critical limits

Establish monitoring procedures

Establish corrective action procedures

Establish verification procedures

Establish record keeping system

Furthermore, based on identified hazards and control points, safety precautions, procedures, and control measures can then be established that are part of a bigger system.

What is a HACCP plan: A HACCP plan can be used to control any area that could introduce potential biological, chemical, or physical hazards into the food stream. Whether it be illness inducing microorganisms, contaminants, chemicals, raw materials, unsafe processes, package labeling, or storage conditions, the HACCP plan is designed to establish critical limits for safety and to prevent and control potential hazards.

Why you need HACCP: The United States Food and Drug Administration (FDA) and Department of Agriculture (USDA) both require mandatory HACCP programs for juice, meat, and seafood in an effort to uphold a level of food safety and to maintain and protect public health. As of July 2019, both organizations have been heavily and strictly enforcing HACCP compliance.

How to HACCP: The development and implementation of a HACCP plan is not an easy task as there are several verification procedures and steps. Many restaurants and companies will hire a HACCP team to handle the burden of developing and writing a HACCP plan as well as the implementation process.

Our HACCP Plan: The iQKitchen HACCP Plan is written and developed by a team of top PhD scientists that understand not only food safety but also guidance, support, and operations. Where we differ from the competition is in our quality, technology, and expertise. Our HACCP plan is written with the held of automated patented technology used for real time temperature validation.

Where iQKitchen differs: All of our HACCP plans have a 100% approval rate because it is written by top PhD scientists and food safety experts. No other company can make this claim. Furthermore, unlike other HACCP plans, our HACCP plans are updated consistently to stay up to date with changes in compliance, new recipes, and regulations. This level of support cannot be found in our competitors. Furthermore, our HACCP plans have a 100% approval rate, which no other competitor has achieved. This allows you, the client, to focus on important tasks for the company, kitchen, or organization while we alleviate pressure by handling all of the food safety.

7 principios de HACCP

HACCP คืออะไร จุดวิกฤต CCP คืออะไร

ติดตาม เนื้อหาสาระจากพวกเราเพิ่มเติมได้ที่

HACCP PLAN

This program covers:

what is haccp definition

What is Haccp stand for?

What is Haccp and why is it important?

What are the steps of Haccp?

What is the main purpose of a Haccp system?

What are the benefits of Haccp?

Haccp a legal requirement?

How long is a Haccp certificate good for?

..

>>ดูข้อมูลอัปเดตเพิ่มเติมได้ที่นี่: ดูความรู้เพิ่มเติมที่นี่

ตัวอย่าง haccp plan – การค้นหาที่เกี่ยวข้อง.

#HACCP #Training #Part #Orange #Juice #simple.

simplyfoodea,Food safety,HACCP,hazard control,HACCP plan example,Hazard Analysis And Critical Control Points,HACCP training,haccp training video,haccp plan,NASA HACCP,HACCP Series,HACCP Concept,haccp flow chart,haccp example,haccp stands for,haccp guidelines,what is haccp,food flow diagram,haccp team,food safety training video,haccp course,haccp steps,haccp presentation,haccp history,haccp principles,haccp usa,haccp canada,haccp australia

#HACCP Training with example Part 1️⃣ (Orange Juice 🍹🍹🍊🍊) in very simple

ตัวอย่าง haccp plan.

ด้วย ความรู้ ในหัวข้อ ตัวอย่าง haccp plan นี้จะ นำความรู้ มาสู่คุณ ขอแสดงความนับถือ.

Critical Control Point ✋🚫vs⚠️Operational Pre-requisite Programs by Decision🌴 (Part 6️⃣ HACCP Tr. )

https://www.youtube.com/watch?v=zRm-awzQ0NM

It's amazing Pleasee make video's on GMP and GHP.

Nice, also see this video on FSSAI

https://youtu.be/k_-0vNNLcNY

Seriously you have a really good channel to learn.. I hope can understand Arab..hope all video will be in English. Really a wonderful example visualized in your every video. Keep this good job. May Allah bless you.

Excellent video and simple to understand! Thanks 🙂

Thank you so much ☺️☺️☺️☺️☺️

Hello. Nice video. 🍊

I have a question though. Is the 5th step a process of auditing or inspection? You are referring to it as an on-site confirmation of the flow diagram, which is true, but does this include inspection or auditing?

I hope I made myself clear. Thank you in advance.

Store in refrigerator at 4-8c ? Where did you get this storage temp from???

Need videos about GMP

💕💕💕

how did you made this presentation? which application did u use?

sorry earlier on i meant NPD not engineering

what happened to both engineering and technical from the haccp team ?

Where is the information relating to scope of product?

hello can you please make one for rum production

MISS MCINTOSH IS A BOSSS

Beautiful.. easy to understand.. love from India

Gracias for sharing as we will be needing USDA certification of our plant in Massachusetts (empanada factory) . . We’ll be hiring a food safety consultant but as owners we also need to understand the importance of “handling food safely” this is HUGE!!! Thanks again for sharing and for being so clear in the way you explained everything. Great Job. You do HACCAP plans for small businesses?

I don't think there is any easier way to explain this.very good job.

Fantastic!

what is concentration step?