You are looking for information, articles, knowledge about the topic nail salons open on sunday near me how does a pulse jet work on Google, you do not find the information you need! Here are the best content compiled and compiled by the Chewathai27.com team, along with other related topics such as: how does a pulse jet work how to make a pulse jet, what is pulse jet engine, Pulse jet engine, Pulse detonation engine, pulse jet kit, pulse jet engine for sale, pulse jet engine pdf, pulse jet engine diagram

A pulsejet engine works by alternately accelerating a contained mass of air rearward and then breathing in a fresh mass of air to replace it. The energy to accelerate the air mass is provided by the deflagration of fuel mixed thoroughly into the newly acquired fresh air mass.Because pulsejets are an efficient and simple way to convert fuel into heat, experimenters are using them for new industrial applications such as biomass fuel conversion, and boiler and heater systems. Some experimenters continue to work on improved designs.The V1 was powered by a Pulse Jet engine (invented by the German Dr. Paul Schmidt several years earlier) and was guided by a gyro servo system that maintained a constant direction of travel during flight. The Pulse Jet produced the characteristic buzzing sound that gave it its name of “buzzbomb”.

Contents

Are pulse jets efficient?

Because pulsejets are an efficient and simple way to convert fuel into heat, experimenters are using them for new industrial applications such as biomass fuel conversion, and boiler and heater systems. Some experimenters continue to work on improved designs.

How did V1 pulse jet work?

The V1 was powered by a Pulse Jet engine (invented by the German Dr. Paul Schmidt several years earlier) and was guided by a gyro servo system that maintained a constant direction of travel during flight. The Pulse Jet produced the characteristic buzzing sound that gave it its name of “buzzbomb”.

Can you throttle a pulse jet?

Hi Dongledell, maybe disapointing for you, but pulse jets have no throttle control. They fly at full speed until the tank is empty and then land in a glide.

Does a pulse jet have a compressor?

The pulse jet engine is an intermittent, compressor less aerodynamic power plant, with few or none of the mechanical features of conventional aviation power plants.

Why are pulse jets not used?

A pulse jet is as inefficient as the dickens in comparison with internal combustion or turbine engines, although a good one can squeeze a lot of flying out of its fuel load. It’s also incredibly loud (the reason why V-1s were referred to as “buzz bombs”).

How loud is a pulse jet?

Bellowing up to 140 decibels, a valveless pulse jet drastically accelerates the speed of bicycles, scooters, skateboards and carousels. “The most common misunderstandings are the engine’s fuel flow—lots—and the starting air—a trickle,” pulse-jet expert Larry Cottrill says.

How does a pulse detonation engine work?

A pulse detonation engine (PDE) is a type of propulsion system that uses detonation waves to combust the fuel and oxidizer mixture. The engine is pulsed because the mixture must be renewed in the combustion chamber between each detonation wave and the next.

What does a doodlebug sound like?

Doodlebugs have been described as making tearing and rasping sounds, but when their motors cut out at a predetermined distance, they became eerily silent, dropping to the ground without a trace.

What are the advantages and disadvantages of pulse jet engines?

…

Cons:

- Thrust grows with flight speed. …

- Low fuel efficiency. …

- High levels of vibration due to the intermittent operation. …

- Need heat-resistant materials.

Who invented pulse jet?

What is a turbo jet aircraft?

A turbojet aircraft is one that is powered by a turbojet engine. Turbojet technology first came about in the 1930s and was first used on military aircraft. With today’s modern jet charter planes, manufacturers prefer to use turbofans and turboprops over turbojets because they: Offer better fuel efficiency.

What is pulse jet valve?

Pulse jet valves are indirect operated solenoid valves especially designed for dust collector systems. When the solenoid is energized, trapped air above a diaphragm is quickly exhausted causing a high pressure difference across the diaphragm. Thereby the diaphragm is suddenly opened.

How is a pulse jet different from a ramjet?

Ramjets differ from pulsejets, which use an intermittent combustion; ramjets employ a continuous combustion process. As speed increases, the efficiency of a ramjet starts to drop as the air temperature in the inlet increases due to compression.

What is pulse jet bag filter?

A pulse jet bag filter, also called a pulse jet baghouse or pulse jet dust collector, is a self-cleaning dry filtration system. The pulse jet dust collector cleaning system removes particulate matter and dust from the surface of internal filter media with bursts of compressed air.

What are the advantages and disadvantages of pulse jet engines?

…

Cons:

- Thrust grows with flight speed. …

- Low fuel efficiency. …

- High levels of vibration due to the intermittent operation. …

- Need heat-resistant materials.

Are Pulsejets powerful?

A valveless pulsejet (or pulse jet) is the simplest known jet propulsion device. Valveless pulsejets are low in cost, light weight, powerful and easy to operate.

How fast can scramjets go?

Theoretical projections place the top speed of a scramjet between Mach 12 (14,000 km/h; 8,400 mph) and Mach 24 (25,000 km/h; 16,000 mph). For comparison, the orbital speed at 200 kilometres (120 mi) low Earth orbit is 7.79 kilometres per second (28,000 km/h; 17,400 mph).

How does a pulse detonation engine work?

A pulse detonation engine (PDE) is a type of propulsion system that uses detonation waves to combust the fuel and oxidizer mixture. The engine is pulsed because the mixture must be renewed in the combustion chamber between each detonation wave and the next.

Valveless pulsejet – Wikipedia

- Article author: en.wikipedia.org

- Reviews from users: 1234

Ratings

- Top rated: 4.8

- Lowest rated: 1

- Summary of article content: Articles about Valveless pulsejet – Wikipedia Updating …

- Most searched keywords: Whether you are looking for Valveless pulsejet – Wikipedia Updating

- Table of Contents:

Contents

Basic characteristics[edit]

Basic (valved) pulsejet theory[edit]

Valveless pulsejet operation[edit]

Practical design issues[edit]

Jam jar jet design[edit]

Pros and cons[edit]

See also[edit]

References[edit]

External links[edit]

Navigation menu

Pulsejet – Wikipedia

- Article author: en.wikipedia.org

- Reviews from users: 47037

Ratings

- Top rated: 3.6

- Lowest rated: 1

- Summary of article content: Articles about Pulsejet – Wikipedia Updating …

- Most searched keywords: Whether you are looking for Pulsejet – Wikipedia Updating

- Table of Contents:

Contents

History[edit]

Design[edit]

Operation[edit]

See also[edit]

References[edit]

Further reading[edit]

External links[edit]

Navigation menu

Pulsejet – Wikipedia

- Article author: users.monash.edu

- Reviews from users: 13892

Ratings

- Top rated: 4.6

- Lowest rated: 1

- Summary of article content: Articles about Pulsejet – Wikipedia Updating …

- Most searched keywords: Whether you are looking for Pulsejet – Wikipedia Updating

- Table of Contents:

Contents

History[edit]

Design[edit]

Operation[edit]

See also[edit]

References[edit]

Further reading[edit]

External links[edit]

Navigation menu

pulse jets – throttle control? – RC Groups

- Article author: www.rcgroups.com

- Reviews from users: 10888

Ratings

- Top rated: 3.2

- Lowest rated: 1

- Summary of article content: Articles about pulse jets – throttle control? – RC Groups Updating …

- Most searched keywords: Whether you are looking for pulse jets – throttle control? – RC Groups Updating pulse jets – throttle control? Fuel Jet Talk

- Table of Contents:

Pulse Jet Engine

- Article author: www.brainkart.com

- Reviews from users: 21637

Ratings

- Top rated: 3.6

- Lowest rated: 1

- Summary of article content: Articles about Pulse Jet Engine Updating …

- Most searched keywords: Whether you are looking for Pulse Jet Engine Updating Mechanical : Gas Dynamics and Jet Propulsion : Jet Propulsion | Pulse Jet Engine | The pulse jet engine is an intermittent, compressor less aerodynamic power plant, with few or none of the mechanical features of conventional aviation

- Table of Contents:

Pulsejet – Wikipedia

- Article author: en.wikipedia.org

- Reviews from users: 17669

Ratings

- Top rated: 3.2

- Lowest rated: 1

- Summary of article content: Articles about Pulsejet – Wikipedia A pulsejet engine (or pulse jet) is a type of jet engine in which combustion occurs in pulses. A pulsejet engine can be made with few or no moving parts, … …

- Most searched keywords: Whether you are looking for Pulsejet – Wikipedia A pulsejet engine (or pulse jet) is a type of jet engine in which combustion occurs in pulses. A pulsejet engine can be made with few or no moving parts, …

- Table of Contents:

Contents

History[edit]

Design[edit]

Operation[edit]

See also[edit]

References[edit]

Further reading[edit]

External links[edit]

Navigation menu

What is a Pulse Jet Engine?

- Article author: www.wikimotors.org

- Reviews from users: 14511

Ratings

- Top rated: 4.1

- Lowest rated: 1

- Summary of article content: Articles about What is a Pulse Jet Engine? A pulse jet engine is an extraordinarily simple device, little more than a hollow tube that produces thrust by burning fuel in a series of … …

- Most searched keywords: Whether you are looking for What is a Pulse Jet Engine? A pulse jet engine is an extraordinarily simple device, little more than a hollow tube that produces thrust by burning fuel in a series of … Brief and Straightforward Guide: What is a Pulse Jet Engine?

- Table of Contents:

You might also Like

Recommended

Related Articles

Discuss this Article

how does a pulse jet work

- Article author: core.ac.uk

- Reviews from users: 12746

Ratings

- Top rated: 4.1

- Lowest rated: 1

- Summary of article content: Articles about how does a pulse jet work 1.2 How Does Valve less Pulsejet Work? Figure 1.2 shows one of the possible layout of a valve less pulsejet engine. It has a chamber with two tubular ports … …

- Most searched keywords: Whether you are looking for how does a pulse jet work 1.2 How Does Valve less Pulsejet Work? Figure 1.2 shows one of the possible layout of a valve less pulsejet engine. It has a chamber with two tubular ports …

- Table of Contents:

Pulse Jet Engines – Tech-FAQ

- Article author: www.tech-faq.com

- Reviews from users: 19333

Ratings

- Top rated: 3.9

- Lowest rated: 1

- Summary of article content: Articles about Pulse Jet Engines – Tech-FAQ Fuel is pulled into the combustion chamber through the intake valve in either an air-gas mixture or liqu form. The intake valve then closes and a spark plug … …

- Most searched keywords: Whether you are looking for Pulse Jet Engines – Tech-FAQ Fuel is pulled into the combustion chamber through the intake valve in either an air-gas mixture or liqu form. The intake valve then closes and a spark plug … A pulse jet engine is a type of jet engine that uses pulses of combustion rather than continuous combustion to stay in the air, thereby reducing fuel costs and increasing efficiency. While pulse jet engines have been used in many functional jets, they can also be used for a variety of other applications such as

- Table of Contents:

How strong is a pulse jet?

- Article author: high-tech-guide.com

- Reviews from users: 14635

Ratings

- Top rated: 4.8

- Lowest rated: 1

- Summary of article content: Articles about How strong is a pulse jet? How does a pulse jet work? … A pulsejet engine works by alternately accelerating a contained mass of air rearward and then breathing in a fresh … …

- Most searched keywords: Whether you are looking for How strong is a pulse jet? How does a pulse jet work? … A pulsejet engine works by alternately accelerating a contained mass of air rearward and then breathing in a fresh … Bellowing up to 140 decibels, a valveless pulse jet drastically accelerates the speed of bicycles, scooters, skateboards and carousels.Mar 15, 2011

- Table of Contents:

How strong is a pulse jet

How does a pulse jet work

What fuel does a pulse jet use

How fast can a pulse jet go

Can you throttle a pulse jet

Pulsejet | Military Wiki | Fandom

- Article author: military-history.fandom.com

- Reviews from users: 16562

Ratings

- Top rated: 4.7

- Lowest rated: 1

- Summary of article content: Articles about Pulsejet | Military Wiki | Fandom The first working pulsejet was patented in 1906 by Russian engineer V.V. … the V-1’s resonant jet could operate while stationary on the launch ramp. …

- Most searched keywords: Whether you are looking for Pulsejet | Military Wiki | Fandom The first working pulsejet was patented in 1906 by Russian engineer V.V. … the V-1’s resonant jet could operate while stationary on the launch ramp. {|class=”infobox ” style=”float: right; clear: right; width: 315px; border-spacing: 2px; text-align: left; font-size: 90%;” ! colspan=”2″ style=”text-align: center; font-size: large; padding-bottom: 0.3em;” | |- |} A pulse jet engine (or pulsejet) is a type of jet engine in which combustion…

- Table of Contents:

Contents

Types

History

Operation

Function

See also

Notes

References

External links

See more articles in the same category here: https://chewathai27.com/toplist.

Valveless pulsejet

Simplest known jet propulsion device

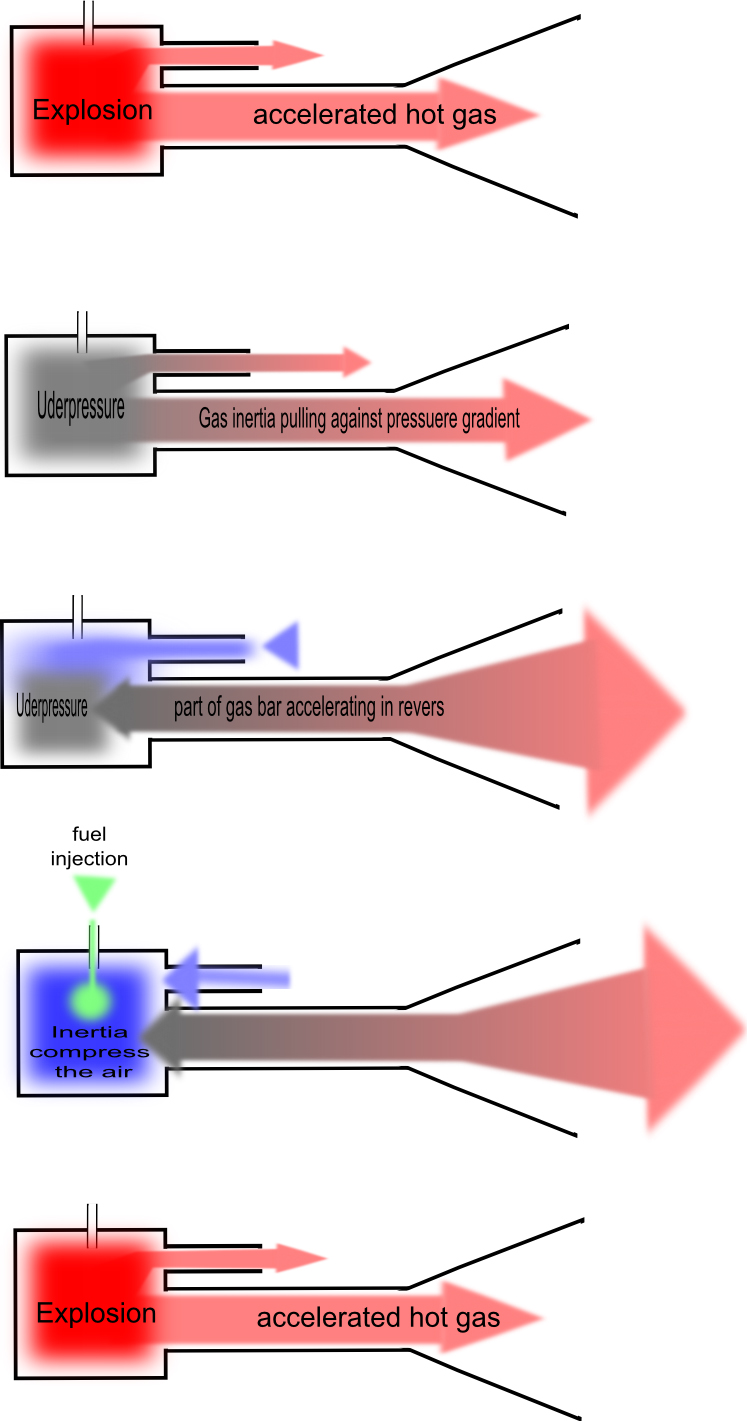

Working mechanism of a valveless pulsejet engine. The basic idea is that the column of air in the long exhaust pipe functions like the piston of a reciprocating engine . From another point of view, the engine is an acoustic resonator internally excited by resonating combustions in the chamber. The chamber acts as a pressure antinode which is compressed by the returning wave. The intake pipe acts as a kinematic antinode which sucks and exhausts gas. Note the longer length of the exhaust pipe—this is important as it prevents oxygen from entering the wrong way and igniting the system the wrong way. It does this because when the pulse ignites, there is still some exhaust gas in the exhaust pipe. That is sucked in before any additional oxygen is sucked in. Of course, the air intake pipe has already supplied the oxygen by that point and the pulse reignites.

A valveless pulsejet (or pulse jet) is the simplest known jet propulsion device. Valveless pulsejets are low in cost, light weight, powerful and easy to operate. They have all the advantages (and most of the disadvantages) of conventional valved pulsejets, but without the reed valves that need frequent replacement – a valveless pulsejet can operate for its entire useful life with practically zero maintenance. They have been used to power model aircraft, experimental go-karts,[1] and unmanned military aircraft such as cruise missiles and target drones.

Basic characteristics [ edit ]

A pulsejet engine is an air-breathing reaction engine that employs an ongoing sequence of discrete combustion events rather than one sustained combustion event. This clearly distinguishes it from other reaction engine types such as rockets, turbojets, and ramjets, which are all constant combustion devices. All other reaction engines are driven by maintaining high internal pressure; pulsejets are driven by an alternation between high and low pressure. This alternation is not maintained by any mechanical contrivance, but rather by the natural acoustic resonance of the rigid tubular engine structure. The valveless pulsejet is, mechanically speaking, the simplest form of pulsejet, and is, in fact, the simplest known air-breathing propulsion device that can operate “statically”, i.e. without forward motion.

The combustion events driving a pulsejet are often informally called explosions; however, the correct term is deflagrations.[2] They are not detonations, which is the combustion event in Pulse Detonation Engines (PDEs). The deflagration within the combustion zone of a pulsejet is characterized by a sudden rise in temperature and pressure followed by a rapid subsonic expansion in gas volume. It is this expansion that performs the main work of moving air rearward through the device as well as setting up conditions in the main tube for the cycle to continue.

A pulsejet engine works by alternately accelerating a contained mass of air rearward and then breathing in a fresh mass of air to replace it. The energy to accelerate the air mass is provided by the deflagration of fuel mixed thoroughly into the newly acquired fresh air mass. This cycle is repeated many times per second. During the brief mass acceleration phase of each cycle, the engine’s physical action is like that of other reaction engines — gas mass is accelerated rearward, resulting in an application of force forward into the body of the engine. These pulses of force, rapidly repeated over time, comprise the measurable thrust force of the engine.

Some basic differences between valved and valveless pulsejets are:

Valveless pulsejet engines have no mechanical valve, eliminating the only internal “moving part” of the conventional pulsejet. [ citation needed ]

In valveless engines, the intake section has an important role to play throughout the entire pulsejet cycle.

Valveless engines produce thrust forces in two distinct but synchronized mass acceleration events per cycle, rather than just one.

Basic (valved) pulsejet theory [ edit ]

In a conventional “valved” pulsejet, like the engine of the infamous V-1 “buzz bomb” of World War II, there are two ducts connected to the combustion zone where the deflagrations occur. These are generally known as the “intake” (a very short duct) and the “tailpipe” (a very long duct). The function of the forward-facing intake is to provide air (and in many smaller pulsejets, the fuel/air mixing action) for combustion. The purpose of the rear-facing tailpipe is to provide air mass for acceleration by the explosive blast as well as to direct the accelerated mass totally rearward. The combustion zone (usually a widened “chamber” section) and tailpipe make up the main tube of the engine. A flexible, low mass one-way valve (or multiple identical valves) separates the intake from the combustion zone.

At the beginning of each cycle, air must be pulled into the combustion zone. At the end of each cycle, the tailpipe must be reloaded with air from the surrounding atmosphere. Both of these basic actions are accomplished by a significant drop in pressure that occurs naturally after the deflagration expansion, a phenomenon known as the Kadenacy effect (named after the scientist who first fully described it). This temporary low pressure opens the metal valve and draws in the intake air (or air/fuel mixture). It also causes a reversal of flow in the tailpipe that draws fresh air forward to re-fill the pipe. When the next deflagration occurs, the rapid pressure rise slams the valve shut very quickly, ensuring that almost no explosion mass exits in the forward direction so the expansion of the combustion gases will all be used to accelerate the replenished mass of air in the long tailpipe rearward.

Valveless pulsejet operation [ edit ]

The valveless pulsejet is not really valveless — it just uses the mass of air in the intake tube as its valve, in place of a mechanical valve. It cannot do this without moving the intake air outward, and this volume of air itself has significant mass, just as the air in the tailpipe does — therefore, it is not blown away instantly by the deflagration but is accelerated over a significant fraction of the cycle time. In all known successful valveless pulsejet designs, the intake air mass is a small fraction of the tailpipe air mass (due to the smaller dimensions of the intake duct). This means that the intake air mass will be cleared out of contact with the body of the engine faster than the tailpipe mass will. The carefully designed imbalance of these two air masses is important for the proper timing of all parts of the cycle.

When the deflagration begins, a zone of significantly elevated pressure travels outward through both air masses as a compression wave. This wave moves at the speed of sound through both the intake and tailpipe air masses. (Because these air masses are significantly elevated in temperature as a result of earlier cycles, the speed of sound in them is much higher than it would be in normal outdoor air.) When a compression wave reaches the open end of either tube, a low pressure rarefaction wave starts back in the opposite direction, as if “reflected” by the open end. This low pressure region returning to the combustion zone is, in fact, the internal mechanism of the Kadenacy effect. There will be no “breathing” of fresh air into the combustion zone until the arrival of the rarefaction wave.

The wave motion through the air masses should not be confused with the separate motions of the masses themselves. At the start of deflagration, the pressure wave immediately moves through both air masses, while the gas expansion (due to combustion heat) is just beginning in the combustion zone. The intake air mass will be rapidly accelerated outward behind the pressure wave, because its mass is relatively small. The tailpipe air mass will follow the outgoing pressure wave much more slowly. Also, the eventual flow reversal will take place much sooner in the intake, due to its smaller air mass. The timing of the wave motions is determined basically by the lengths of the intake and main tube of the engine; the timing of mass motions is determined mostly by the volumes and exact shapes of these sections. Both are affected by local gas temperatures.

In the valveless engine, there will actually be two arrivals of rarefaction waves — first, from the intake and then from the tailpipe. In typical valveless designs, the wave that comes back from the intake will be relatively weak. Its main effect is to begin flow reversal in the intake itself, in effect “pre-loading” the intake duct with fresh outdoor air. The actual breathing of the engine as a whole will not begin in earnest until the major low pressure wave from the tailpipe reaches the combustion zone. Once that happens, significant flow reversal begins, driven by the drop in combustion zone pressure.

During this phase, too, there is a difference in action between the very different masses in the intake and tailpipe. The intake air mass is again fairly low, but it now almost totally consists of outside air; therefore, fresh air is available almost immediately to begin re-filling the combustion zone from the front. The tailpipe air mass is also pulled, eventually reversing direction as well. The tailpipe will never be completely purged of hot combustion gases, but at reversal it will be easily able to pull in fresh air from all sides around the tailpipe opening, so its contained mass will be gradually increasing until the next deflagration event. As air flows rapidly into the combustion zone, the rarefaction wave is reflected rearward by the front of the engine body, and as it moves rearward the air density in the combustion zone naturally rises until the pressure of the air/fuel mixture reaches a value where deflagration can again commence.

Practical design issues [ edit ]

In practical designs there is no need for a continuous ignition system — the combustion zone is never totally purged of combustion gases and free radicals, so there is enough chemical action in the residue in the combustion zone to act as an igniter for the next blast once the mixture is up to a reasonable density and pressure: the cycle repeats, controlled only by the synchronization of pressure and flow events in the two ducts.

While it is theoretically possible to have such an engine without a distinct “combustion chamber” larger than the tailpipe diameter, all successful valveless engines designed so far have a widened chamber of some sort, roughly similar to that found in typical valved engine designs. The chamber typically takes up a fairly small fraction of the overall main tube length.

The acceleration of air mass back through the intake duct doesn’t make sense for engine thrust if the intake is aimed forward, since the intake thrust is a fairly large fraction of the tailpipe thrust. Various engine geometries have been used to make the thrust forces from the two ducts act in the same direction. One simple method is to turn the engine around and then put a U-bend in the tailpipe, so both ducts are spouting rearward, as in the Ecrevisse and Lockwood (also known as Lockwood-Hiller) types. The Escopette and Kentfield designs use recuperators (U-shaped auxiliary tubes) mounted in front of the front-firing intakes to turn the intake blast and flow rearward. The so-called “Chinese” and Thermojet styles simply mount the intake on the chamber in a rear-spouting direction, leaving the front face of the chamber unbroken. The basic internal operation of the engine with these geometries is no different from that described above, however. The Lockwood is unique in one respect, namely, its very large diameter intake — the thrust from this large tube is no less than 40 percent of the engine thrust as a whole. The tailpipe volume of this design is quite large, though, so the imbalance of the contained masses is still clearly seen.

“Jam jar jet” design [ edit ]

Work mechanism of jam jar jet. (b) Mixture of air and fuel vapors could ignite using external igniter or by residual free radicals from last work cycle. (a) The previous jet expelled more air than conform to equilibrium pressure in chamber, thus some of the fresh air is sucked back. The pressure drop in this case is caused more by cooling of the gas in chamber than by gas momentum. Gas momentum can not be used well in this design because of lack of exhaust (resonator) pipe and very dissipative aerodynamics of the aperture.

Most pulsejet engines use independent intake and exhaust pipes. A physically simpler design combines the intake and exhaust aperture. This is possible due to the oscillating behaviour of a pulse engine. One aperture can act as exhaust pipe during the high-pressure phase of the work cycle and as intake during the aspiration phase. This engine design is less efficient in this primitive form due to its lack of a resonant pipe and thus a lack of reflected compressing and sucking acoustic waves. However it works fairly well with a simple instrument such as jam jar with a pierced lid and fuel inside, hence the name.

Successful versions of the jam jar jet have been run in a plastic bottle. The bottle is far less efficient than the jam jar versions and is unable to sustain a decent jet for more than a few seconds. It is theorized that the alcohol that was used to operate the simple jet was acting as a barrier to stop the heat getting all the way through to the plastic. For the jam jar jet design to work the propellant must be vaporised to ignite which is most often done by a shaking of the jet which causes the propellant to coat the container, therefore giving the theory some validity.[citation needed]

Pros and cons [ edit ]

Successful valveless pulsejets have been built from a few centimeters in length to huge sizes, though the largest and smallest have not been used for propulsion. The smallest ones are only successful when extremely fast-burning fuels are employed (acetylene or hydrogen, for example). Medium and larger sized engines can be made to burn almost any flammable material that can be delivered uniformly to the combustion zone, though of course volatile flammable liquids (gasoline, kerosene, various alcohols) and standard fuel gases (LPG, propane, butane, MAPP gas) are easiest to use. Because of the deflagration nature of pulsejet combustion, these engines are extremely efficient combustors, producing practically no hazardous pollutants, other than CO 2 [citation needed], even when using hydrocarbon fuels. With modern high-temperature metals for the main structure, engine weight can be kept extremely low. Without the presence of a mechanical valve, the engines require practically no ongoing maintenance to remain operational.

Up to the present, the physical size of successful valveless designs has always been somewhat larger than valved engines for the same thrust value, though this is theoretically not a requirement. Like valved pulsejets, heat (engines frequently run white hot) and very high operational noise levels (140 decibels is possible)[2] are among the greatest disadvantages of these engines. An ignition system of some sort is required for engine startup. In the smallest sizes, forced air at the intake is also typically needed for startup. There is still much room for improvement in the development of really efficient, fully practical designs for propulsion uses.

One possible solution to the ongoing problem of pulsejet inefficiency would be to have two pulsejets in one, with each blast compressing the mixture of fuel and air in the other, and both ends discharging into a common chamber through which air flows only one way. This could potentially allow much higher compression ratios, better fuel efficiencies, and greater thrust.[3]

See also [ edit ]

Wikipedia

Engine where combustion is pulsed instead of continuous

Diagram of a pulsejet

A pulsejet engine (or pulse jet) is a type of jet engine in which combustion occurs in pulses. A pulsejet engine can be made with few[1] or no moving parts,[2][3][4] and is capable of running statically (i.e. it does not need to have air forced into its inlet, typically by forward motion).

Pulsejet engines are a lightweight form of jet propulsion, but usually have a poor compression ratio, and hence give a low specific impulse.

There are two main types of pulsejet engines, both of which use resonant combustion and harness the expanding combustion products to form a pulsating exhaust jet that produces thrust intermittently. The first is known as a valved or traditional pulsejet and it has a set of one-way valves through which the incoming air passes. When the air-fuel is ignited, these valves slam shut, which means that the hot gases can only leave through the engine’s tailpipe, thus creating forward thrust. The second type of pulsejet is known as the valveless pulsejet.[5] Technically the term for this engine is the acoustic-type pulsejet, or aerodynamically valved pulsejet.

One notable line of research of pulsejet engines includes the pulse detonation engine, which involves repeated detonations in the engine, and which can potentially give high compression and reasonably good efficiency.

History [ edit ]

Ramon Casanova and the pulsejet engine he constructed and patented in 1917

Russian inventor and retired artillery officer Nikolaj Afanasievich Teleshov patented a steam pulsejet engine in 1867 while Swedish inventor Martin Wiberg also has a claim to having invented the first pulsejet, in Sweden, but details are unclear.

The first working pulsejet was patented in 1906 by Russian engineer V.V. Karavodin, who completed a working model in 1907. The French inventor Georges Marconnet patented his valveless pulsejet engine in 1908, and Ramon Casanova, in Ripoll, Spain patented a pulsejet in Barcelona in 1917, having constructed one beginning in 1913. Robert Goddard invented a pulsejet engine in 1931, and demonstrated it on a jet-propelled bicycle.[6] Engineer Paul Schmidt pioneered a more efficient design based on modification of the intake valves (or flaps), earning him government support from the German Air Ministry in 1933.[7]

In 1909, Georges Marconnet developed the first pulsating combustor without valves. It was the grandfather of all valveless pulsejets. The valveless pulsejet was experimented with by the French propulsion research group SNECMA (Société Nationale d’Étude et de Construction de Moteurs d’Aviation ), in the late 1940s.

The valveless pulsejet’s first widespread use was the Dutch drone Aviolanda AT-21[8]

Argus As 109-014 [ edit ]

In 1934, Georg Hans Madelung and Munich-based Paul Schmidt proposed to the German Air Ministry a “flying bomb” powered by Schmidt’s pulsejet. Madelung co-invented the ribbon parachute, a device used to stabilise the V-1 in its terminal dive.[citation needed] Schmidt’s prototype bomb failed to meet German Air Ministry specifications, especially owing to poor accuracy, range and high cost. The original Schmidt design had the pulsejet placed in a fuselage like a modern jet fighter, unlike the eventual V-1, which had the engine placed above the warhead and fuselage.[citation needed]

The Argus Company began work based on Schmidt’s work. Other German manufacturers working on similar pulsejets and flying bombs were The Askania Company, Robert Lusser of Fieseler, Dr. Fritz Gosslau of Argus and the Siemens company, which were all combined to work on the V-1.[7]

With Schmidt now working for Argus, the pulsejet was perfected and was officially known by its RLM designation as the Argus As 109-014. The first unpowered drop occurred at Peenemünde on 28 October 1942 and the first powered flight on 10 December 1942.[citation needed]

The pulsejet was evaluated to be an excellent balance of cost and function: a simple design that performed well for minimal cost.[7] It would run on any grade of petroleum and the ignition shutter system was not intended to last beyond the V-1’s normal operational flight life of one hour. Although it generated insufficient thrust for takeoff, the V-1’s resonant jet could operate while stationary on the launch ramp. The simple resonant design based on the ratio (8.7:1) of the diameter to the length of the exhaust pipe functioned to perpetuate the combustion cycle, and attained stable resonance frequency at 43 cycles per second. The engine produced 2,200 N (490 lb f ) of static thrust and approximately 3,300 N (740 lb f ) in flight.[7]

Ignition in the As 014 was provided by a single automotive spark plug, mounted approximately 75 cm (30 in) behind the front-mounted valve array. The spark only operated for the start sequence for the engine; the Argus As 014, like all pulsejets, did not require ignition coils or magnetos for ignition — the ignition source being the tail of the preceding fireball during the run. The engine casing did not provide sufficient heat to cause diesel-type ignition of the fuel, as there is insignificant compression within a pulsejet engine.[citation needed]

The Argus As 014 valve array was based on a shutter system that operated at the 43 to 45 cycles-per-second frequency of the engine.[citation needed]

Three air nozzles in the front of the Argus As 014 were connected to an external high pressure source to start the engine. The fuel used for ignition was acetylene, with the technicians having to place a baffle of wood or cardboard in the exhaust pipe to stop the acetylene diffusing before complete ignition. Once the engine ignited and minimum operating temperature was attained, external hoses and connectors were removed.

The V-1, being a cruise missile, lacked landing gear, instead the Argus As 014 was launched on an inclined ramp powered by a piston-driven steam catapult. Steam power to fire the piston was generated by the violent exothermic chemical reaction created when hydrogen peroxide and potassium permanganate (termed T-Stoff and Z-Stoff) are combined.

The principal military use of the pulsejet engine, with the volume production of the Argus As 014 unit (the first pulsejet engine ever in volume production), was for use with the V-1 flying bomb. The engine’s characteristic droning noise earned it the nicknames “buzz bomb” or “doodlebug”. The V-1 was a German cruise missile used in World War II, most famously in the bombing of London in 1944. Pulsejet engines, being cheap and easy to construct, were the obvious choice for the V-1’s designers, given the Germans’ materials shortages and overstretched industry at that stage of the war. Designers of modern cruise missiles do not choose pulsejet engines for propulsion, preferring turbojets or rocket engines. The only other uses of the pulsejet that reached the hardware stage in Nazi Germany were the Messerschmitt Me 328 and an experimental Einpersonenfluggerät project for the German Heer.

Wright Field technical personnel reverse-engineered the V-1 from the remains of one that had failed to detonate in Britain. The result was the creation of the JB-2 Loon, with the airframe built by Republic Aviation, and the Argus As 014 reproduction pulsejet powerplant, known by its PJ31 American designation, being made by the Ford Motor Company.

General Hap Arnold of the United States Army Air Forces was concerned that this weapon could be built of steel and wood, in 2000 man hours and approximate cost of US$600 (in 1943).[7]

Design [ edit ]

Animation of a pulsejet engine

Pulsejet engines are characterized by simplicity, low cost of construction, and high noise levels. While the thrust-to-weight ratio is excellent, thrust specific fuel consumption is very poor. The pulsejet uses the Lenoir cycle, which, lacking an external compressive driver such as the Otto cycle’s piston, or the Brayton cycle’s compression turbine, drives compression with acoustic resonance in a tube. This limits the maximum pre-combustion pressure ratio, to around 1.2 to 1.

The high noise levels usually make them impractical for other than military and other similarly restricted applications.[8] However, pulsejets are used on a large scale as industrial drying systems, and there has been a resurgence in studying these engines for applications such as high-output heating, biomass conversion, and alternative energy systems, as pulsejets can run on almost anything that burns, including particulate fuels such as sawdust or coal powder.

Pulsejets have been used to power experimental helicopters, the engines being attached to the ends of the rotor blades. In providing power to helicopter rotors, pulsejets have the advantage over turbine or piston engines of not producing torque upon the fuselage since they don’t apply force to the shaft, but push the tips. A helicopter may then be built without a tail rotor and its associated transmission and drive shaft, simplifying the aircraft (cyclic and collective control of the main rotor is still necessary). This concept was being considered as early as 1947 when the American Helicopter Company started work on its XA-5 Top Sergeant helicopter prototype powered by pulsejet engines at the rotor tips.[9] The XA-5 first flew in January 1949 and was followed by the XA-6 Buck Private with the same pulsejet design. Also in 1949 Hiller Helicopters built and tested the Hiller Powerblade, the world’s first hot-cycle pressure-jet rotor. Hiller switched to tip mounted ramjets but American Helicopter went on to develop the XA-8 under a U.S. Army contract. It first flew in 1952 and was known as the XH-26 Jet Jeep. It used XPJ49 pulsejets mounted at the rotor tips. The XH-26 met all its main design objectives but the Army cancelled the project because of the unacceptable level of noise of the pulsejets and the fact that the drag of the pulsejets at the rotor tips made autorotation landings very problematic. Rotor-tip propulsion has been claimed to reduce the cost of production of rotary-wing craft to 1/10 of that for conventional powered rotary-wing aircraft.[8]

Pulsejets have also been used in both control-line and radio-controlled model aircraft. The speed record for control-line pulsejet-powered model aircraft is greater than 200 miles per hour (323 km/h).

The speed of a free-flying radio-controlled pulsejet is limited by the engine’s intake design. At around 450 km/h (280 mph) most valved engines’ valve systems stop fully closing owing to ram air pressure, which results in performance loss.

Variable intake geometry lets the engine produce full power at most speeds by optimizing for whatever speed at which the air enters the pulsejet. Valveless designs are not as negatively affected by ram air pressure as other designs, as they were never intended to stop the flow out of the intake, and can significantly increase in power at speed.

Another feature of pulsejet engines is that their thrust can be increased by a specially shaped duct placed behind the engine. The duct acts as an annular wing, which evens out the pulsating thrust, by harnessing aerodynamic forces in the pulsejet exhaust. The duct, typically called an augmentor, can significantly increase the thrust of a pulsejet with no additional fuel consumption. Gains of 100% increases in thrust are possible, resulting in a much higher fuel efficiency. However, the larger the augmenter duct, the more drag it produces, and it is only effective within specific speed ranges.

Operation [ edit ]

Valved designs [ edit ]

Pulsejet schematic. First part of the cycle: air flows through the intake (1), and is mixed with fuel (2). Second part: the valve (3) is closed and the ignited fuel-air mix (4) propels the craft.

Valved pulsejet engines use a mechanical valve to control the flow of expanding exhaust, forcing the hot gas to go out of the back of the engine through the tailpipe only, and allow fresh air and more fuel to enter through the intake as the inertia of the escaping exhaust creates a partial vacuum for a fraction of a second after each detonation. This draws in additional air and fuel between pulses.

The valved pulsejet comprises an intake with a one-way valve arrangement. The valves prevent the explosive gas of the ignited fuel mixture in the combustion chamber from exiting and disrupting the intake airflow, although with all practical valved pulsejets there is some ‘blowback’ while running statically or at low speed, as the valves cannot close fast enough to prevent some gas from exiting through the intake. The superheated exhaust gases exit through an acoustically resonant exhaust pipe.

The intake valve is typically a reed valve. The two most common configurations are the daisy valve, and the rectangular valve grid. A daisy valve consists of a thin sheet of material to act as the reed, cut into the shape of a stylized daisy with “petals” that widen towards their ends. Each “petal” covers a circular intake hole at its tip. The daisy valve is bolted to the manifold through its centre. Although easier to construct on a small scale, it is less effective than a valve grid.

The cycle frequency is primarily dependent on the length of the engine. For a small model-type engine the frequency may be around 250 pulses per second, whereas for a larger engine such as the one used on the German V-1 flying bomb, the frequency was closer to 45 pulses per second. The low-frequency sound produced resulted in the missiles being nicknamed “buzz bombs.”

Valveless designs [ edit ]

Valveless pulsejet engines have no moving parts and use only their geometry to control the flow of exhaust out of the engine. Valveless pulsejets expel exhaust out of both the intakes and the exhaust, but the majority of the force produced leaves through the wider cross section of the exhaust. The larger amount of mass leaving the wider exhaust has more inertia than the backwards flow out of the intake, allowing it to produce a partial vacuum for a fraction of a second after each detonation, reversing the flow of the intake to its proper direction, and therefore ingesting more air and fuel. This happens dozens of times per second.

The valveless pulsejet operates on the same principle as the valved pulsejet, but the ‘valve’ is the engine’s geometry. Fuel, as a gas or atomized liquid spray, is either mixed with the air in the intake or directly injected into the combustion chamber. Starting the engine usually requires forced air and an ignition source, such as a spark plug, for the fuel-air mix. With modern manufactured engine designs, almost any design can be made to be self-starting by providing the engine with fuel and an ignition spark, starting the engine with no compressed air. Once running, the engine only requires input of fuel to maintain a self-sustaining combustion cycle.

The combustion cycle comprises five or six phases depending on the engine: Induction, Compression, (optional) Fuel Injection, Ignition, Combustion, and Exhaust.

Starting with ignition within the combustion chamber, a high pressure is raised by the combustion of the fuel-air mixture. The pressurized gas from combustion cannot exit forward through the one-way intake valve and so exits only to the rear through the exhaust tube.

The inertial reaction of this gas flow causes the engine to provide thrust, this force being used to propel an airframe or a rotor blade. The inertia of the traveling exhaust gas causes a low pressure in the combustion chamber. This pressure is less than the inlet pressure (upstream of the one-way valve), and so the induction phase of the cycle begins.

In the simplest of pulsejet engines this intake is through a venturi, which causes fuel to be drawn from a fuel supply. In more complex engines the fuel may be injected directly into the combustion chamber. When the induction phase is under way, fuel in atomized form is injected into the combustion chamber to fill the vacuum formed by the departing of the previous fireball; the atomized fuel tries to fill up the entire tube including the tailpipe. This causes atomized fuel at the rear of the combustion chamber to “flash” as it comes in contact with the hot gases of the preceding column of gas—this resulting flash “slams” the reed-valves shut or in the case of valveless designs, stops the flow of fuel until a vacuum is formed and the cycle repeats.

Valveless pulsejets come in a number of shapes and sizes, with different designs being suited for different functions. A typical valveless engine will have one or more intake tubes, a combustion chamber section, and one or more exhaust tube sections.

The intake tube takes in air and mixes it with fuel to combust, and also controls the expulsion of exhaust gas, like a valve, limiting the flow but not stopping it altogether. While the fuel-air mixture burns, most of the expanding gas is forced out of the exhaust pipe of the engine. Because the intake tube(s) also expel gas during the exhaust cycle of the engine, most valveless engines have the intakes facing backwards so that the thrust created adds to the overall thrust, rather than reducing it.

The combustion creates two pressure wave fronts, one traveling down the longer exhaust tube and one down the short intake tube. By properly ‘tuning’ the system (by designing the engine dimensions properly), a resonating combustion process can be achieved.

While some valveless engines are known for being extremely fuel-hungry, other designs use significantly less fuel than a valved pulsejet, and a properly designed system with advanced components and techniques can rival or exceed the fuel efficiency of small turbojet engines.

A properly designed valveless engine will excel in flight as it does not have valves, and ram air pressure from traveling at high speed does not cause the engine to stop running like a valved engine. They can achieve higher top speeds, with some advanced designs being capable of operating at Mach .7 or possibly higher.

The advantage of the acoustic-type pulsejet is simplicity. Since there are no moving parts to wear out, they are easier to maintain and simpler to construct.

Future uses [ edit ]

Pulsejets are used today in target drone aircraft, flying control line model aircraft (as well as radio-controlled aircraft), fog generators, and industrial drying and home heating equipment. Because pulsejets are an efficient and simple way to convert fuel into heat, experimenters are using them for new industrial applications such as biomass fuel conversion, and boiler and heater systems.[citation needed]

Some experimenters continue to work on improved designs. The engines are difficult to integrate into commercial manned aircraft designs because of noise and vibration, though they excel on the smaller-scale unmanned vehicles.

The pulse detonation engine (PDE) marks a new approach towards non-continuous jet engines and promises higher fuel efficiency compared to turbofan jet engines, at least at very high speeds. Pratt & Whitney and General Electric now have active PDE research programs. Most PDE research programs use pulsejet engines for testing ideas early in the design phase.

Boeing has a proprietary pulsejet engine technology called Pulse Ejector Thrust Augmentor (PETA), which proposes to use pulsejet engines for vertical lift in military and commercial VTOL aircraft.[10]

See also [ edit ]

References [ edit ]

Further reading [ edit ]

throttle control?

gutboy17 Registered User

I think I’m going to have to disagree with the throttling of the fuel flow. In my experience trying to meter the fuel flow rate to these touchy creatures is too complicated. I’ve witnessed a few pulse-jetters try this with a modified turbine fuel control module in a controlled wind tunnel and the results were less than satisfactory. The jet usually flamed out due to a too lean of a fuel-air mixture. This test wasn’t just a hip shot by some tinkerers either. The guys conducting the test spent many many months mapping the thrust-specific fuel consumption for the jet’s operating envolpe.

The next step of trying to throttle the pulse jet was to intermittantly interrupt the fuel flow to the jet via an electronic controlled solenoid fuel shutoff valve. The principle was to control the combustion pulses much like a ESC cycles power to an electric motor to control its speed. Less setup did have its limitations. At static conditions it was not possible to control thrust in this fashion due to any interruption in fuel flow would usually result in a flame out. At low ram air speeds this method was still unstable and difficult to control thrust. On the high end of ram air speeds this method did work and was managable. However, it did sound kind of cheesy having the jet pulse shut off and on periodically. Sound like the jet was sick.

The last setup was to control the ram air flow into the venturi of the Dyna jet. The first setup consisted of a iris style air flow valve in front of the inlet. At static conditions it was possible to throttle the thrust levels down just a little bit from a full open inlet conditions. If I remember correctly the static thrust is some where around 4lbs. and we were able to throttle the static thrust down to 2.75 to 3lbs. From the static condition we were able to control thrust at any air speed in the wind tunnel from the jets full open inlet ram air thrust levels down to ~3lbs of thrust. The second part of this step was to hone the ram air control by replacing the iris valve with an axial adjustable pintle. The concept was to fabricate a pintle that its axial position in the pulse jet’s inlet could be adjusted to control the air flow mass into the jet. I left the project before this was completed, but I did hear that they were almost done with the setup and were going to be starting testing fairly soon.

Another test that will soon be conducted is the control of the pulse jet’s thrust by controlling exhaust gas temperatures. This was left to last because the designing and building of the heat exchanger was a little over our heads at the time.

So you have finished reading the how does a pulse jet work topic article, if you find this article useful, please share it. Thank you very much. See more: how to make a pulse jet, what is pulse jet engine, Pulse jet engine, Pulse detonation engine, pulse jet kit, pulse jet engine for sale, pulse jet engine pdf, pulse jet engine diagram