You are looking for information, articles, knowledge about the topic nail salons open on sunday near me how much refrigerant can you put in a recovery tank on Google, you do not find the information you need! Here are the best content compiled and compiled by the https://chewathai27.com team, along with other related topics such as: how much refrigerant can you put in a recovery tank how much refrigerant can a 30 lb recovery tank hold, how much refrigerant can i put in a recovery tank, how much refrigerant can a 50 lb recovery tank hold, refrigerant recovery tank sizes, refrigerant recovery tank capacity formula, how to tell what refrigerant is in a recovery tank, 100 lb recovery cylinder capacity, refrigerant cylinder size chart

By law, a tank can only be filled to 80% capacity and must be kept under 122°F. It is recommended to fill to 2 lbs less than the 80%. For example, a 30 lb cylinder can hold 22 lbs of refrigerant and a 50 lb cylinder can hold 38 lbs of refrigerant.Do not overfill the container. Recovery cylinders should not be filled if the present date is more than five years past the test date that is stamped on the shoulder of the cylinder.The water capacity of a recovery cylinder normally is stamped on the outside of the cylinder. For example, if a recovery cylinder has a water capacity of 47.17 pounds, then its internal volume will be 0.75 cubic feet (47.17 pounds ÷ 62.5 pounds/cubic foot = 0.75 cubic feet).

| Item | Refrigerant Recovery Cylinder |

|---|---|

| Recovery Tank Size | 30 lb |

| Weight Empty (Lb.) | 15.6 |

| Height (In.) | 17 15/16 in |

| Width (In.) | 9 1/16 in |

| Cylinder name | Water capacity | Allowable refrigerants(2) |

|---|---|---|

| 30 lb | 26.2 lb 726 in3 | All(1) except R-410A |

| All(1) | ||

| 50 lb | 47.7 lb 1323 in3 | All(1) except R-410A |

| All(1) |

Contents

Can you overfill a recovery tank?

Do not overfill the container. Recovery cylinders should not be filled if the present date is more than five years past the test date that is stamped on the shoulder of the cylinder.

How do you calculate recovery tank capacity?

The water capacity of a recovery cylinder normally is stamped on the outside of the cylinder. For example, if a recovery cylinder has a water capacity of 47.17 pounds, then its internal volume will be 0.75 cubic feet (47.17 pounds ÷ 62.5 pounds/cubic foot = 0.75 cubic feet).

How much does a 30 lb recovery tank weigh full?

| Item | Refrigerant Recovery Cylinder |

|---|---|

| Recovery Tank Size | 30 lb |

| Weight Empty (Lb.) | 15.6 |

| Height (In.) | 17 15/16 in |

| Width (In.) | 9 1/16 in |

How much 410A can a recovery tank hold?

| Cylinder name | Water capacity | Allowable refrigerants(2) |

|---|---|---|

| 30 lb | 26.2 lb 726 in3 | All(1) except R-410A |

| All(1) | ||

| 50 lb | 47.7 lb 1323 in3 | All(1) except R-410A |

| All(1) |

Why do recovery tanks have two valves?

In order to store the recovered freon, there is a cylinder equipped with two access valves. In order to maintain the homogeneity and purity of the substance, it is necessary to collect and store each type of refrigerant in a dedicated and appropriately marked cylinder.

How much does a 30 lb recovery tank weigh empty?

Refrigerant Recovery Cylinder: 30 lb Recovery Tank Size, 15.6 lb Wt Empty (Lb.)

How much should a 50 lb recovery tank weigh when full?

Size (w x h): 12.25″ x 18.78″ Tare Weight: 28.71 lb.

What does WC mean on a recovery cylinder?

Updated: Apr 23, 2020. In order to determine how much refrigerant can be added in a used recovery bottle, first the neck of the recovery bottle must be read. This will show the WC (water column capacity) and the TW (tare weight). The bottle can only be filled with refrigerant to 80% of the WC.

What can I do with recovered refrigerant?

If you send recovered ODS refrigerant for reclamation, the ODS refrigerant shipment must be sent to an EPA-certified refrigerant reclaimer. You can view a list at www.epa.gov/ ozone/title6/608/reclamation/reclist.

How much do recovery tanks weigh empty?

When empty, the Standard 2 lbs recovery tank weighs 31 lbs. When empty, the recovery tank weighs 37 lbs. 55 lbs is the empty weight of the recovery tank.

What does WC mean on a tank?

Most propane grill tanks come with two numbers stamped on the handle – the water capacity (“WC”) and “Tare Weight” (TW – the weight of the tank when it’s empty). Most grilling tanks weigh about 17 pounds when empty and hold about 20 pounds of gas.

Can a refrigerant recovery machine be used as a vacuum pump?

Just wondering if any manufacturer of recovery units can double as a vacuum pump? He11 yes, they all can. You can use the rec machine to get the air out of the system and filter-driers to take care of moisture.

How much refrigerant can you put in a 50 lb recovery cylinder?

NEVER Exceed Refrigerant Recovery Tank Limits

For example, a 30 lb cylinder can hold 22 lbs of refrigerant and a 50 lb cylinder can hold 38 lbs of refrigerant.

What does TW mean on a recovery tank?

In order to determine how much refrigerant can be added in a used recovery bottle, first the neck of the recovery bottle must be read. This will show the WC (water column capacity) and the TW (tare weight). The bottle can only be filled with refrigerant to 80% of the WC.

How often does a reusable container for refrigerant need to be hydrostatically tested?

Reusable refrigerant containers that are normally under any pressure above 15 psig, must be hydrostatically tested and date stamped every 5 years.

Do recovery cylinders need to be labeled?

Recovery cylinders and drums must be painted gray with the shoulder portion painted yellow, per DOT regulations. Label cylinders and drums with a 4- by 4-in. green, nonflammable gas label. Label your cylinders with the type of refrigerant recovered.

Chadwell Supply. 8 Tips on Refrigerant Recovery

- Article author: www.chadwellsupply.com

- Reviews from users: 21969

Ratings

- Top rated: 4.5

- Lowest rated: 1

- Summary of article content: Articles about Chadwell Supply. 8 Tips on Refrigerant Recovery Updating …

- Most searched keywords: Whether you are looking for Chadwell Supply. 8 Tips on Refrigerant Recovery Updating Use these eight tips to help your multifamily property in the process of recovering, recycling and reclaiming refrigerant.

- Table of Contents:

8 Tips on Refrigerant Recovery

Step-by-Step Refrigerant Recovery Process

Other Related Resources

Toll Free

888-341-2423

Hear about deals events & news!

Safe Refrigerant Recovery | ACHR News

- Article author: www.achrnews.com

- Reviews from users: 38795

Ratings

- Top rated: 3.5

- Lowest rated: 1

- Summary of article content: Articles about Safe Refrigerant Recovery | ACHR News Updating …

- Most searched keywords: Whether you are looking for Safe Refrigerant Recovery | ACHR News Updating The authors provide some tips to help you recover refrigerants safely and avoid possible personal injury or damage to your equipment. Many of these recommendations are the same as for handling refrigerants in their original container.achr,hvac,hvacr,the news,hvac news,hvacr news,achrnews,air conditioning heating refrigeration news,air conditioning,heating,refrigeration,superheat,subcooling,troubleshooting,hvacr directory,hvac directory,btu buddy

- Table of Contents:

SAFETY RECOMMENDATIONS

CYLINDER SELECTION AND HANDLING

R-22 COMPARISONS WITH R-410A

BOTTOM LINE

Report Abusive Comment

The Future of HVAC Refrigerants Are You Ready

Installation Techniques for Air Treatment Solutions

Examining Recovery Cylinder Capabilities | ACHR News

- Article author: www.achrnews.com

- Reviews from users: 25566

Ratings

- Top rated: 4.2

- Lowest rated: 1

- Summary of article content: Articles about Examining Recovery Cylinder Capabilities | ACHR News Updating …

- Most searched keywords: Whether you are looking for Examining Recovery Cylinder Capabilities | ACHR News Updating Working with refrigerant recovery cylinders is a basic part of servicing refrigeration systems. Technicians need to work safely when handling these cylinders.

achr,hvac,hvacr,the news,hvac news,hvacr news,achrnews,air conditioning heating refrigeration news,air conditioning,heating,refrigeration,superheat,subcooling,troubleshooting,hvacr directory,hvac directory,btu buddy - Table of Contents:

MAXIMUM WEIGHT

Understanding Vacuum Level Measurements

Refrigerant Leaks in Self-Contained Systems

Determining the Correct Refrigerant Charge

Installing Thermostatic Expansion Valves

Components and Equipment More Expensive Hard to Get

Report Abusive Comment

The Future of HVAC Refrigerants Are You Ready

Installation Techniques for Air Treatment Solutions

Forane® Refrigerant reclaim program – Acceptable cylinder information

- Article author: forane.arkema.com

- Reviews from users: 23334

Ratings

- Top rated: 4.6

- Lowest rated: 1

- Summary of article content: Articles about Forane® Refrigerant reclaim program – Acceptable cylinder information Updating …

- Most searched keywords: Whether you are looking for Forane® Refrigerant reclaim program – Acceptable cylinder information Updating View information about the Forane® Refrigerant reclaim program, including recovery cylinder information, service pressure, and refrigerant match-up.Arkema,Arkema,Inc.,Forane®,Refrigerants,Industrial,refrigeration,Commercial,refrigeration,Refrigeration,Reclaim,program,Cylinder,information,Refrigerant,match-up

- Table of Contents:

Recovery Tank Capacity – HVAC School

- Article author: hvacrschool.com

- Reviews from users: 23526

Ratings

- Top rated: 3.1

- Lowest rated: 1

- Summary of article content: Articles about Recovery Tank Capacity – HVAC School You cannot fill above 80% with liqu, or you risk building up the hydrostatic pressure and exploding the tank. · Refrigerant does not have the … …

- Most searched keywords: Whether you are looking for Recovery Tank Capacity – HVAC School You cannot fill above 80% with liqu, or you risk building up the hydrostatic pressure and exploding the tank. · Refrigerant does not have the …

- Table of Contents:

Recovery Tank Capacity

Related Tech Tips

Interested in a HVAC Career

Error 403 (Forbidden)

- Article author: www.quora.com

- Reviews from users: 47799

Ratings

- Top rated: 3.0

- Lowest rated: 1

- Summary of article content: Articles about Error 403 (Forbidden) Usually 6–9 lbs. of refrigerant, depending on the manufacturer. Many A/C units will typically have 2–3 lbs. per ton (1–1.5 kg per ton … …

- Most searched keywords: Whether you are looking for Error 403 (Forbidden) Usually 6–9 lbs. of refrigerant, depending on the manufacturer. Many A/C units will typically have 2–3 lbs. per ton (1–1.5 kg per ton …

- Table of Contents:

How much refrigerant can a recovery tank hold?

- Article author: hvac-talk.com

- Reviews from users: 21314

Ratings

- Top rated: 3.7

- Lowest rated: 1

- Summary of article content: Articles about How much refrigerant can a recovery tank hold? Typically, the tanks are rated for 50 & 30 pounds, so they can (legally) hold 40 & 24 pounds respectively. rundawg’s Avatar. rundawg sa: 07-30 … …

- Most searched keywords: Whether you are looking for How much refrigerant can a recovery tank hold? Typically, the tanks are rated for 50 & 30 pounds, so they can (legally) hold 40 & 24 pounds respectively. rundawg’s Avatar. rundawg sa: 07-30 … I was recently asked by someone how much refrigerant can a recovery tank hold. I told them up to 80%. Then they said 80% of what. So.. that brings me here. I’ve looked for the answer myself and found some stuff but I wanna hear what everyone has to say. So, How much refrigerant can a recovery tank hold?

- Table of Contents:

How much refrigerant can a recovery tank hold

how much refrigerant can you put in a recovery tank

- Article author: chadwellsupply.s3.amazonaws.com

- Reviews from users: 4250

Ratings

- Top rated: 3.1

- Lowest rated: 1

- Summary of article content: Articles about how much refrigerant can you put in a recovery tank If using a new recovery cylinder, make sure it is labeled at FIRST use. 2. Label the Tank. 8. Dispose Properly. Cylinders CANNOT be put in the trash. …

- Most searched keywords: Whether you are looking for how much refrigerant can you put in a recovery tank If using a new recovery cylinder, make sure it is labeled at FIRST use. 2. Label the Tank. 8. Dispose Properly. Cylinders CANNOT be put in the trash.

- Table of Contents:

how much refrigerant can you put in a recovery tank

- Article author: content.interlinebrands.com

- Reviews from users: 4508

Ratings

- Top rated: 3.3

- Lowest rated: 1

- Summary of article content: Articles about how much refrigerant can you put in a recovery tank All tare weights and dimensions are approximate. To convert to refrigerant capacity: Maximum allowable gross cylinder fill weight is 0.8 x water capacity x … …

- Most searched keywords: Whether you are looking for how much refrigerant can you put in a recovery tank All tare weights and dimensions are approximate. To convert to refrigerant capacity: Maximum allowable gross cylinder fill weight is 0.8 x water capacity x …

- Table of Contents:

how much refrigerant can you put in a recovery tank

- Article author: icemeister.net

- Reviews from users: 41679

Ratings

- Top rated: 4.8

- Lowest rated: 1

- Summary of article content: Articles about how much refrigerant can you put in a recovery tank •Refrigerant’s density at 130 0F. • * R-410A Temperature for Safe Storage is limited to 125 0F. Page 2. Fill Capacity assuming the 50 lb recovery cylinder … …

- Most searched keywords: Whether you are looking for how much refrigerant can you put in a recovery tank •Refrigerant’s density at 130 0F. • * R-410A Temperature for Safe Storage is limited to 125 0F. Page 2. Fill Capacity assuming the 50 lb recovery cylinder …

- Table of Contents:

Examining Recovery Cylinder Capabilities | ACHR News

- Article author: www.achrnews.com

- Reviews from users: 13996

Ratings

- Top rated: 4.3

- Lowest rated: 1

- Summary of article content: Articles about Examining Recovery Cylinder Capabilities | ACHR News To prevent overfilling, recovery cylinders should not be filled to more than 80 percent of their internal volume. Most technicians accomplish … …

- Most searched keywords: Whether you are looking for Examining Recovery Cylinder Capabilities | ACHR News To prevent overfilling, recovery cylinders should not be filled to more than 80 percent of their internal volume. Most technicians accomplish … Working with refrigerant recovery cylinders is a basic part of servicing refrigeration systems. Technicians need to work safely when handling these cylinders.

achr,hvac,hvacr,the news,hvac news,hvacr news,achrnews,air conditioning heating refrigeration news,air conditioning,heating,refrigeration,superheat,subcooling,troubleshooting,hvacr directory,hvac directory,btu buddy - Table of Contents:

MAXIMUM WEIGHT

Understanding Vacuum Level Measurements

Refrigerant Leaks in Self-Contained Systems

Determining the Correct Refrigerant Charge

Installing Thermostatic Expansion Valves

Components and Equipment More Expensive Hard to Get

Report Abusive Comment

The Future of HVAC Refrigerants Are You Ready

Installation Techniques for Air Treatment Solutions

How Much Refrigerant Can I Put In A Recovery Tank? – Rush Answers

- Article author: rushanswers.com

- Reviews from users: 17972

Ratings

- Top rated: 3.1

- Lowest rated: 1

- Summary of article content: Articles about How Much Refrigerant Can I Put In A Recovery Tank? – Rush Answers Just exactly how much will it price to recuperate refrigerant? Really best refrigerant recovery device? How numerous pounds associated with … …

- Most searched keywords: Whether you are looking for How Much Refrigerant Can I Put In A Recovery Tank? – Rush Answers Just exactly how much will it price to recuperate refrigerant? Really best refrigerant recovery device? How numerous pounds associated with … How A Lot Refrigerant May I Location In The Recovery Container? It Is Suggested In Order To Fill In Order To 2 Pounds Lower Compared To T…

- Table of Contents:

How a lot refrigerant may I location in the recovery container

Just exactly how much will it price to recuperate refrigerant

Really best refrigerant recovery device

How numerous pounds associated with Freon really does a few ton device hold

The reason why is refrigerant recovery required

What will be the quickest way in order to restore refrigerant

Exactly how does heat effect refrigerant recovery procedure

Whenever recovery is definitely first began at exactly what phase

Extremely best technique to discover out the chillers regular charge

Exactly what can occur when making use of a big vacuum cleaner pump in order to evacuate the system

When ought to refrigerant end up being removed through the condenser outlet

Each time a program is within deep vacuum cleaner you need to never

What safety measure should become taken earlier to recuperating refrigerant through the refrigerator suspected associated with having pipe leaks

Just how would a person remove dampness from refrigerant inside a program

Exactly what goes upon if dampness is remaining in the particular system

Is the vacuum the particular best technique of eliminating considerable amounts associated with moisture through a program

What will go on in order to a program that leakages while within vacuum stress

Exactly what vapors will a heavy vacuum get out associated with the program

Simply how lengthy does this decide to try draw a strong vacuum

Exactly what is regarded as a great vacuum degree for any heavy vacuum

When the strategy can be in the deep vacuum cleaner

Is this necessary in order to pull vacuum cleaner pressure upon a small split

Are usually you capable to set up a small split program yourself

How several microns need to vacuum stress pump draw down in order to

How Much Refrigerant Can a Recovery Cylinder Hold

How To Tell How Much Refrigerant There is in a Recovery Tank

Don’t Overfill Refrigerant Recovery Cylinders The Easy Way

HVAC 123 Recovery Tanks part 1

Recovery tank

Categories

You Might Also Enjoy

See more articles in the same category here: https://chewathai27.com/toplist.

Chadwell Supply. 8 Tips on Refrigerant Recovery

It’s no secret that refrigerant is expensive and you are busy! Being able to safely recover refrigerant to reuse it on your property is important, but also recovering it as quickly as possible is helpful too. Use these eight tips to help you in the process of recovering, recycling and reclaiming refrigerant.

1. NEVER Exceed Refrigerant Recovery Tank Limits

By law, a tank can only be filled to 80% capacity and must be kept under 122°F.

It is recommended to fill to 2 lbs less than the 80%. For example, a 30 lb cylinder can hold 22 lbs of refrigerant and a 50 lb cylinder can hold 38 lbs of refrigerant.

You must calculate to make sure the recovery tank will safely accept the amount of refrigerant being added:

Find the current amount of refrigerant in tank (A). Weigh the recovery tank on a refrigerant scale. Subtract the tare weight (stamped on tank’s side).

Find the amount of refrigerant in the unit by checking the unit’s faceplate (B)

Add the current refrigerant amount from the tank (A) and the amount of refrigerant in the unit (B).

If the result is less than the 80% requirement, then there is enough space for the refrigerant. If the result is more, then an additional cylinder is needed.

(Note: if the tank is empty, the scale should match the tare weight stamped onto the side of the cylinder.)

Safe Refrigerant Recovery

When servicing equipment, refrigerant recovery is a legal requirement. It has been a mandated part of the servicing process since 1993. However, we still receive a number of questions, which raise our concern for the safety of service technicians when performing this essential function. Therefore, we thought it timely to provide some tips that can help you recover refrigerants safely and avoid possible personal injury or damage to your equipment. Many of these recommendations are the same as for handling refrigerants in their original container.

SAFETY RECOMMENDATIONS

• Use personal protective equipment including safety glasses with side shields, gloves, and safety shoes when filling and handling recovery containers. Use a hard hat if required for the work area.

• Avoid skin contact with liquid refrigerant because it can cause frostbite.

• Because refrigerant vapor is heavier than air, it will concentrate in low areas. Avoid these areas unless proper ventilation is provided.

• Avoid inhalation of refrigerant vapor. Be aware that inhalation of high concentrations of refrigerant vapor is harmful and may cause heart irregularities, unconsciousness, or death.

• Recovered refrigerant will typically contain some amount of oil, which can appear as a white cloud or fog. Do not breathe oil mist if it should be emitted during the recovery process.

• Exercise caution when moving filled recovery containers.

• It is recommended that all service technicians periodically review the product MSDS to be reminded of important safety information.

Some additional recommendations apply specifically to the recovery process and recovery cylinders:

• Prior to filling, inspect the recovery container and valve for signs of damage, such as dents or corrosion. Do not fill a damaged recovery container.

• Make sure the cylinder is properly labeled with the type of refrigerant.

• Do not mix refrigerants in the recovery cylinder.

• Ensure that the recovery equipment, recovery cylinder and hoses are rated for the refrigerant you are recovering; check with your equipment supplier.

• Do not overfill the container.

• Recovery cylinders should not be filled if the present date is more than five years past the test date that is stamped on the shoulder of the cylinder.

CYLINDER SELECTION AND HANDLING

Due to their higher pressure, R-410A and R-402A (HP-80) must be recovered in a 4BA400 or 4BW400 high-pressure recovery cylinder. Some refrigerants like R-422A, R-422D, R-407C, R-404A, R-408A, and R-507 can be recovered in a standard 4BA300 or 4BW300 recovery cylinder; however, these same refrigerants must be recovered in a high-pressure 4BW400 half-ton recovery tank since the lower pressure half tons are only rated for 260 psig. For recommended recovery cylinders by refrigerant, please consult the manufacturer/refrigerant supplier.

Do not overfill the cylinder. Liquid refrigerant will expand as its temperature is increased. If the cylinder somehow becomes completely full of liquid, the pressure can increase dramatically with a relatively small increase in temperature.

Refrigerant manufacturers and others who fill cylinders have to know how much refrigerant to put in the cylinders so as not to become liquid full under normal storage/use temperatures, and even at temperatures that far exceed these normal conditions. Now that recovery of used refrigerant is becoming a common practice, contractors and service technicians also need to understand this.

Typically, the cylinder should not be filled to more than 80 percent liquid full at 77°F. Another guideline is to not exceed the gross weight (total weight of the container and its contents). Check with your refrigerant supplier or reclaim provider for specific recommendations.

Most people in the HVACR industry who routinely handle refrigerant cylinders understand the concept of “saturation pressure vs. temperature.”

When there is some amount of liquid refrigerant in a cylinder, the pressure associated with a given temperature will be the saturation pressure. This is the information that is provided in pocket P-T charts that are commonly used in the industry.

If there is only refrigerant vapor in the cylinder, then the vapor is described as a “superheated vapor” and the pressure associated with a given temperature does not follow the standard P-T curves.

If the cylinder somehow becomes completely full of liquid, then other pressure-temperature relationships take over and there is the possibility of an unsafe situation. In a “liquid full condition” the pressure in the cylinder can increase very rapidly with relatively minor increases in the temperature. The design pressure of the cylinder can be exceeded and the cylinder relief valve could begin to vent the high-pressure refrigerant. In a worst-case scenario, the cylinder could burst, causing property damage or personal injury. Table 1 shows pressure-rating data for two commonly used recovery cylinders.

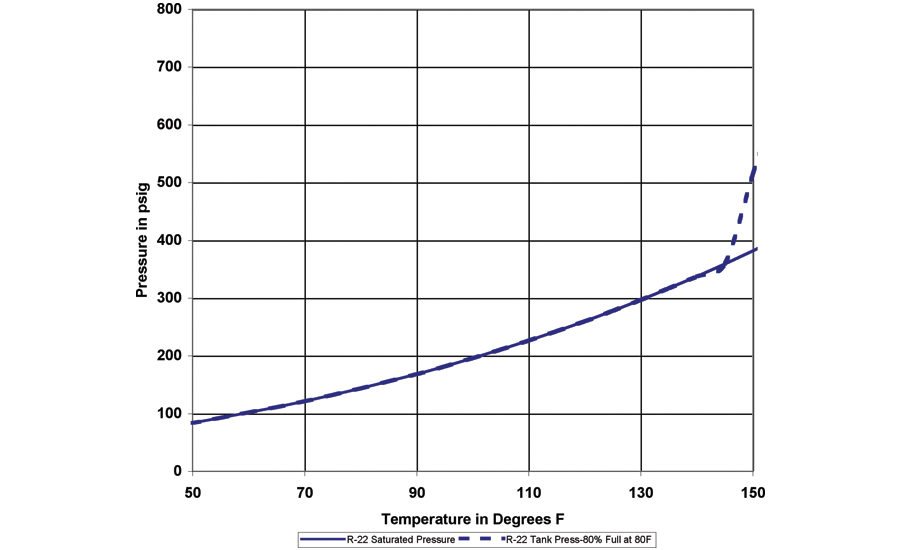

R-22 COMPARISONS WITH R-410A

To demonstrate the effect of temperature and pressure, a series of calculations were conducted on R-22 and R-410A. Fig. 1 assumes that a recovery cylinder, filled with R-22, was properly filled to a safe liquid level of 80 percent at 80°. As the temperature increases, the liquid refrigerant expands inside the cylinder, but the pressure will still follow the saturated P-T curve until it becomes liquid full at 145°.

At this point the pressure begins to increase rapidly with increasing temperature. In most normal situations, a cylinder would not reach this temperature unless it is in a fire or stored in a location subject to very high heat loads. The minimum relief valve setting for a DOT-4BA300 cylinder will be exceeded if the cylinder reaches 145°.

Fig. 2 shows the same information as Fig. 1, but with additional information on R-410A. It is interesting to note that R-410A starts out at a higher pressure, but does not increase as rapidly in pressure as R-22 when the cylinder becomes liquid full at 145°.

Fig. 3 shows R-22 with two additional curves. These two curves assume the cylinders are improperly overfilled to 90 percent and 95 percent liquid level at 80°.

As indicated in the graph, these two cylinders would become liquid full at a much lower temperature (about 130° and 105° respectively). In these two situations, it is much more likely that the relief valve would be activated, especially for the cylinder that was improperly overfilled to 95 percent liquid full. It is also possible the cylinder burst pressure could be exceeded.

The relief valve is designed to prevent this from happening. But in an extreme case, such as a fire, the capacity of the relief valve could be exceeded.

Note: R-22 was used as an example because it is broadly used and familiar to most in the HVACR industry. Most other commonly used refrigerants would exhibit very similar behavior under similar conditions.

BOTTOM LINE

When recovering used refrigerant, follow the recommended practices summarized above. Thoroughly inspect the cylinder you will use and ensure it is designed to handle the pressure of the refrigerant being recovered. EPA has also established under Section 608 that refrigerant recovered and/or recycled can be returned to the same system or other systems owned by the same person without restriction.

If refrigerant changes ownership, however, that refrigerant must be reclaimed (i.e., cleaned to the ARI 700-1993 standard of purity and chemically analyzed to verify that it meets this standard) at an EPA-certified reclamation facility. Remember that R-410A re- quires a DOT-4BA400 or 4BW400 recovery cylinder. Never overfill the recovery cylinder.

DuPont offers reclaim services to its distributors for all of its refrigerants and is available to assist with questions regarding your recovery needs. Further information can be obtained at www.refrigerants.dupont.com or 800-235-7882.

Publication date: 01/29/2007

Examining Recovery Cylinder Capabilities

Working with refrigerant recovery cylinders is a basic part of servicing refrigeration systems. Technicians need to work safely when handling these cylinders.

Overfilling these cylinders can create a potential hazard. To prevent overfilling, recovery cylinders should not be filled to more than 80 percent of their internal volume. Most technicians accomplish this by placing the recovery cylinders on an electronic scale and monitoring the weight of the cylinder during the recovery process. When the cylinder reaches a weight equal to 80 percent of its total capacity, the technician stops the recovery process and changes cylinders if needed.

In order to use this method effectively, a technician must know the cylinder’s weight equal to 80 percent of its maximum capacity. This maximum weight will vary slightly as different refrigerants are used in recovery cylinders and different refrigerants have different liquid densities.

MAXIMUM WEIGHT

There are two basic ways to accurately determine the maximum weight of a recovery cylinder:

1. Find the recovery cylinder manufacturer’s published data for various refrigerants.

2. Calculate this value.

To determine this value, use the following procedure:

1. Calculate the internal volume of the recovery cylinder being used. This can be accomplished by dividing the water capacity of the cylinder by the density of water, which is 62.5 pounds/cubic foot. The water capacity of a recovery cylinder normally is stamped on the outside of the cylinder. For example, if a recovery cylinder has a water capacity of 47.17 pounds, then its internal volume will be 0.75 cubic feet (47.17 pounds ÷ 62.5 pounds/cubic foot = 0.75 cubic feet).

2. For the refrigerant to be recovered, determine its liquid density at a saturation temperature of 130°F. Refrigerant manufacturers publish the various saturation properties of their refrigerants, including liquid density at various saturation temperatures. For example, if R-134a were to be recovered, its liquid density at a 130° saturation temperature is 67.46 pounds/cubic foot.

3. Determine the tare weight of the recovery cylinder, which is the weight of the cylinder if it were empty. This is also stamped on the outside of the cylinder. For example, for a nominal 50-pound recovery cylinder, the tare weight would be 24 pounds.

4. Use the following formula to determine the maximum cylinder weight:

Maximum cylinder weight = (cylinder volume x liquid density of the refrigerant at 130°F x 0.80) + tare weight

For example, if the cylinder is holding R-134a, (with its liquid density of 67.46 pounds/cubic foot at 130° saturation temperature) had a water capacity of 47.17 pounds and a tare weight of 24 pounds, the maximum cylinder weight would be:

Cylinder volume = water capacity ÷ density of water (62.5 pounds/cubic foot)

Cylinder volume = 47.17 pounds ÷ 62.5 pounds/cubic foot = 0.75cubic feet

Maximum cylinder weight = (0.75 cubic feet x 67. pounds/cubic foot x 0.80) + 24 pounds = 64.48 pounds.

A technician should not continue to fill this recovery cylinder once its weight has exceeded 64.48 pounds. Again, overfilling a recovering cylinder can lead to very serious injury.

Publication Date: 12/03/2007

So you have finished reading the how much refrigerant can you put in a recovery tank topic article, if you find this article useful, please share it. Thank you very much. See more: how much refrigerant can a 30 lb recovery tank hold, how much refrigerant can i put in a recovery tank, how much refrigerant can a 50 lb recovery tank hold, refrigerant recovery tank sizes, refrigerant recovery tank capacity formula, how to tell what refrigerant is in a recovery tank, 100 lb recovery cylinder capacity, refrigerant cylinder size chart