You are looking for information, articles, knowledge about the topic nail salons open on sunday near me how to install aluminum cladding on Google, you do not find the information you need! Here are the best content compiled and compiled by the https://chewathai27.com team, along with other related topics such as: how to install aluminum cladding ALUCOBOND, Facade stone cladding, Alucobond Vietnam, vinyl siding overlap direction, can you put new vinyl siding over old vinyl siding, can you bend vinyl siding, curved siding, vinyl siding curved wall

Contents

How do you install ACM?

- Prepare the environment for the ACM installation.

- Create a new OpenShift project and namespace.

- Create an image-pull secret.

- Install ACM and subscribe to the ACM Operator group.

- Create the MultiClusterHub resource.

- Verify the ACM installation.

How do you make a composite aluminum panel?

The composite panel is produced by a continuous lamination process, in which a sheet of the material that will make up the core is extruded and compacted between two aluminium sheets that are unwound at the same time. Finally, the flatness of the material is compacted and perfected and a protective film is applied.

What is cladding on aluminum?

From this trade name the adjective clad and the verb cladding have been derived. An example of clad aluminum is the surface of unpainted aircraft. Not all aircraft sheet aluminum is clad, especially those alloy sheets from which small brackets, gussets, and fittings are made.

What is Aluminium composite panel used for?

ACP sheet or Aluminium Composite Panel is a new-age cladding material that’s used for building front elevation (facades), interiors, signage, modular kitchen and many more. It is available in a wide range of colours and textures like wood, stone, sand, 3D etc.

How much does ACM panel cost?

Fabricated ACM typically ranges anywhere from $15-‐$35 per SF of coverage area in the majority of situations. The vast range in cost can be contributed to the many fabricators and their unique engineered systems, color selections, paint finishes, architectural design, orientation, thickness and type of plank material.

What is ACM metal panel?

Aluminum composite material (ACM) is a three-layer sandwich panel consisting of two pre-painted aluminum sheets bonded to a polyethylene (PE) core. ACM panels are an excellent material for indoor or outdoor applications that require good dimensional stability, low weight, and a sleek, brilliant look.

How ACP cladding is done?

Out of numerous cladding materials in the market, the one which is on the rage for the last couple of decades is ACP cladding. ACP cladding is done from ACP sheets, these sheets are made of thin aluminum sheets fixed with a thermoplastic core, making them look like sandwich panels.

Is Aluminium composite panel flexible?

Malleable Capability of the Aluminum Composite Panel

Aluminum is flexible, meaning that the material is ideal for operations such as cutting, shaping, and drilling. Aluminum composite panels often appear on building facades. They are available in various shapes depending on the type of facade.

What is ACP wall cladding?

Get Latest Price. Aluminum Composite Panel (ACP) or Aluminum Composite Material (ACM) is a widely-used term describing flat panels that consist of a non-aluminum core bonded between two aluminum sheets. Aluminum sheets can be coated with PVDF or Polyester paint.

What is cladding on aluminum?

From this trade name the adjective clad and the verb cladding have been derived. An example of clad aluminum is the surface of unpainted aircraft. Not all aircraft sheet aluminum is clad, especially those alloy sheets from which small brackets, gussets, and fittings are made.

What is Aluminium composite panel used for?

ACP sheet or Aluminium Composite Panel is a new-age cladding material that’s used for building front elevation (facades), interiors, signage, modular kitchen and many more. It is available in a wide range of colours and textures like wood, stone, sand, 3D etc.

What is Alucobond cladding?

Alucobond is a light, versatile and widely used type of composite cladding, made up of two aluminium cover sheets and a core material within (usually polyethylene). The material itself is stable yet flexible, with a smooth surface.

Aluminium Composite Panel Installation Rout and Return Method – YouTube

- Article author: www.youtube.com

- Reviews from users: 8880

Ratings

- Top rated: 3.2

- Lowest rated: 1

- Summary of article content: Articles about Aluminium Composite Panel Installation Rout and Return Method – YouTube Updating …

- Most searched keywords: Whether you are looking for Aluminium Composite Panel Installation Rout and Return Method – YouTube Updating This video tells how Aluminium Composite Panel be installed, following the Rout and Return Wet Seal Method.Visit this link to read guidelines on ACP fabricat…rout and return wet seal method, the tray system of ACP installation, ACP, Aluminium Composite Panel, Aluminium, Quality, Innovation, Premium, Aludecor, Decor, Interior, Exterior, Real Estate, Fire, Retardant, Building, Material, Prevention, Safety, Architect, Aesthetic, Minimalist, Rain, Cladding, Protection, Copper, Signage, Firewall, Lamination, India, Testing Lab, laboratory, Recycle, fabricator, Lifestyle, Design, Assist, Urban, Residential, Office, Reliable, Safe, Project, Home, House, Facades, installation

- Table of Contents:

INSTALLING ALUMINUM COMPOSITE PANELS (ACM)! Without fancy tools! SIMPLE! – YouTube

- Article author: www.youtube.com

- Reviews from users: 2534

Ratings

- Top rated: 3.4

- Lowest rated: 1

- Summary of article content: Articles about INSTALLING ALUMINUM COMPOSITE PANELS (ACM)! Without fancy tools! SIMPLE! – YouTube Updating …

- Most searched keywords: Whether you are looking for INSTALLING ALUMINUM COMPOSITE PANELS (ACM)! Without fancy tools! SIMPLE! – YouTube Updating This video will help anyone who is getting into business working with Aluminum Composite Panels.aluminum composite panel, aluminum composite panels, ACM, aluminum composite material, how to install aluminum composite panels, how to install aluminum composite panel, how to make aluminum composite panel, ACM installation

- Table of Contents:

Installing Red Hat Advanced Cluster Management (ACM) for Kubernetes | Red Hat Developer

- Article author: developers.redhat.com

- Reviews from users: 33991

Ratings

- Top rated: 4.4

- Lowest rated: 1

- Summary of article content: Articles about Installing Red Hat Advanced Cluster Management (ACM) for Kubernetes | Red Hat Developer Updating …

- Most searched keywords: Whether you are looking for Installing Red Hat Advanced Cluster Management (ACM) for Kubernetes | Red Hat Developer Updating Learn how to set up your Red Hat OpenShift 4 environment for a Red Hat Advanced Cluster Management (ACM) for Kubernetes installation, and then install ACM.

- Table of Contents:

ACM installation overview

Step 1 Prepare the environment for the ACM Installation

Step 2 Create a new OpenShift project namespace

Step 3 Create an image-pull secret

Step 4 Install ACM and subscribe to the ACM Operator group

Install and subscribe using the CLI

Step 5 Create the MultiClusterHub resource

Step 6 Verify the ACM installation

Conclusion

Recent Articles

Comments

Aluminium composite panel. Everything you need to know

- Article author: stacbond.com

- Reviews from users: 42559

Ratings

- Top rated: 4.5

- Lowest rated: 1

- Summary of article content: Articles about Aluminium composite panel. Everything you need to know Updating …

- Most searched keywords: Whether you are looking for Aluminium composite panel. Everything you need to know Updating There is one thing we can all agree on within the construction industry, and it is that the popularity of aluminum composite panel

- Table of Contents:

ALUMINIUM COMPOSITE PANEL WHAT IS IT AND WHICH ARE ITS MAIN USES

A versatile recyclable and quick to install product

CUSTOMISED FINISHES

IMPOSSIBLE SHAPES

RESISTENT PANELS

How to Install Aluminum Cladding | HomeSteady

- Article author: homesteady.com

- Reviews from users: 18240

Ratings

- Top rated: 4.0

- Lowest rated: 1

- Summary of article content: Articles about How to Install Aluminum Cladding | HomeSteady Start at the back of the wall, so panels overlap with the front one on top, to prove a more finished look. Add panels, slipping the bottom of … …

- Most searched keywords: Whether you are looking for How to Install Aluminum Cladding | HomeSteady Start at the back of the wall, so panels overlap with the front one on top, to prove a more finished look. Add panels, slipping the bottom of … Aluminum siding has been used to clad or cover building exteriors since World War II. Today’s versions offer options that resemble cedar shingles, traditional wood clapboard or other types of house cladding. Today’s aluminum siding comes with prefinished coatings that defy weather and rot. Aluminum also is more of a …

- Table of Contents:

Cleaning

Interior

HVAC

Electrical

DIY

Exterior

Maintenance

Paint

Laundry

Step 1

Step 2

Step 3

Step 4

how to install aluminum cladding

- Article author: www.alpolic.com

- Reviews from users: 15140

Ratings

- Top rated: 4.7

- Lowest rated: 1

- Summary of article content: Articles about how to install aluminum cladding ALPOLIC/fr 4mm Aluminum extrusion ] . 20 |. Sealing material. Page 9. 8. Internal wall cladding-hanging method. …

- Most searched keywords: Whether you are looking for how to install aluminum cladding ALPOLIC/fr 4mm Aluminum extrusion ] . 20 |. Sealing material. Page 9. 8. Internal wall cladding-hanging method.

- Table of Contents:

ACM Panel Installation Guide – Wiedehopf® | Building Façade Systems

- Article author: wiedehopf.ca

- Reviews from users: 10105

Ratings

- Top rated: 4.9

- Lowest rated: 1

- Summary of article content: Articles about ACM Panel Installation Guide – Wiedehopf® | Building Façade Systems Aluminum composite panel installation steps: Measurement: The first step or probably the pre-step of installing a panel is to measure the size of it. The … …

- Most searched keywords: Whether you are looking for ACM Panel Installation Guide – Wiedehopf® | Building Façade Systems Aluminum composite panel installation steps: Measurement: The first step or probably the pre-step of installing a panel is to measure the size of it. The … ACM panel installation might initially look challenging, the installation process of aluminum composite material is straightforward.

- Table of Contents:

What are aluminum composite materials

ACM panel installation

ACM panel installation guide for indoor application

ACM panel installation guide for outdoor application

Final words

Pros and Cons of Aluminum Siding

Why Hyundai Keeps Revisiting Their Exterior Designs A Case Study

Vinyl vs Aluminum Siding What’s The Difference

How to Install Aluminum Sidings – Aluminum composite panel in Toronto

- Article author: alumtech.ca

- Reviews from users: 17299

Ratings

- Top rated: 3.1

- Lowest rated: 1

- Summary of article content: Articles about How to Install Aluminum Sidings – Aluminum composite panel in Toronto Aluminum sings are one of the trendiest products in the building industry that architects use to create a more efficient cladding systems. …

- Most searched keywords: Whether you are looking for How to Install Aluminum Sidings – Aluminum composite panel in Toronto Aluminum sings are one of the trendiest products in the building industry that architects use to create a more efficient cladding systems. Aluminum sidings are one of the trendiest products in the building industry that architects use to create a more efficient cladding systems.

- Table of Contents:

Pre-Installation Measurement for Ideal Results

Aluminum Sidings Installation Guideline

Required Tools and Equipment

ALPOLIC ACM panels in Canada

ACM Panels Details for Buildings in Canada

The Horizontal Installation Method of Rainscreens

Aluminum Composite Panels Installation Procedure

- Article author: profelez.ca

- Reviews from users: 5399

Ratings

- Top rated: 4.9

- Lowest rated: 1

- Summary of article content: Articles about Aluminum Composite Panels Installation Procedure Aluminum Composite Panels are modern materials that are very practical for external cladding applications for different types of buildings. …

- Most searched keywords: Whether you are looking for Aluminum Composite Panels Installation Procedure Aluminum Composite Panels are modern materials that are very practical for external cladding applications for different types of buildings. Aluminum Composite Panels are modern materials that are very practical for external cladding applications for different types of buildings

- Table of Contents:

Thermal Conditions of Aluminum Composite Panels

Removing Protective Film from the Aluminum Composite Panels

ACP Installation Direction

Installation Methods

How to Install ACM Aluminium Composite Panel & Planks Cladding?

- Article author: al13.com

- Reviews from users: 25821

Ratings

- Top rated: 3.3

- Lowest rated: 1

- Summary of article content: Articles about How to Install ACM Aluminium Composite Panel & Planks Cladding? Learn here how to install the AL13® ACM Panel and Plank Cladding Systems from the unboxing all the way to the finished product. …

- Most searched keywords: Whether you are looking for How to Install ACM Aluminium Composite Panel & Planks Cladding? Learn here how to install the AL13® ACM Panel and Plank Cladding Systems from the unboxing all the way to the finished product. Learn here how to install the AL13® ACM Panel and Plank Cladding Systems from the unboxing all the way to the finished product.

- Table of Contents:

Here’s a full walkthrough of AL13®

01

UNITED STATES

02

CANADA

See more articles in the same category here: 670+ tips for you.

Installing Red Hat Advanced Cluster Management (ACM) for Kubernetes

Red Hat Advanced Cluster Management (ACM) for Kubernetes offers end-to-end visibility and control for managing your cluster and application lifecycle. Among other features, it ensures security and compliance for your entire Kubernetes domain across multiple data centers and public clouds.

This article guides you through setting up your Red Hat OpenShift 4 environment for an ACM installation and then installing ACM. For reasons that I will explain, we’ll use the command line interface (CLI) to set up the installation environment. Once the environment is set up, I will show you how to complete the installation using either the CLI or the OpenShift web console, with examples for both methods.

Note that I will not demonstrate how to install ACM in a restricted environment. Also, my examples are based on Advanced Cluster Management for Kubernetes 1.0. Tech Preview. You might need to update some of the installation steps for a newer version of ACM.

Note: See Red Hat Advanced Cluster Management for Kubernetes for more about the features and benefits of ACM.

ACM installation overview

You can use either the OpenShift 4 web console’s built-in OperatorHub or the OpenShift CLI to install ACM. The installation breaks down to six steps:

Prepare the environment for the ACM installation. Create a new OpenShift project and namespace. Create an image-pull secret. Install ACM and subscribe to the ACM Operator group. Create the MultiClusterHub resource. Verify the ACM installation.

We will use the OpenShift command line for the first several steps; then, I will show you how to use either the command line or the OpenShift 4 web console.

Step 1: Prepare the environment for the ACM Installation

Before starting with the installation process, make sure that you have the correct version of OpenShift and other resources set up in your development environment. Before you start setting up your development environment for ACM, make sure that you have OpenShift 4.3 or higher installed on Linux x86_64 and Red Hat Enterprise Linux (RHEL) 7.6 or higher.

There are a number of important details to consider before proceeding. One is the number of pods per node. The number of pods you need depends on the application type and how you configure the worker nodes. The maximum pod per node is 500 and the maximum pod per CPU core is 10.

Another is that the cluster size depends on the number of worker nodes. If your cluster has a few worker nodes, consider increasing the number of worker nodes while decreasing the size of each node for adequate headspace, efficiency, mobility, and resiliency.

Note: Learn more about minimum and maximum node configuration and pod resource sizing.

You also need to consider the memory that is required for the specific type of workload you will be running, plus for the other application frameworks in your environment. And, you have to be prepared to accommodate workload mobility.

As an example, if your OpenShift installation is running on Amazon Web Services (AWS), it is recommended that you use a node size of m5.2xlarge or above. Figure 1 shows the configuration options for ACM clusters running on AWS.

Figure 1: Cluster maximums for running ACM on Amazon Web Services.

If you are a cluster admin, you can increase the size of worker nodes using machineset sizing operations. To upgrade to a node size of m5.2xlarge:

List the machinesets:

$ oc get machinesets -n openshift-machine-api

Next, upgrade the instance type of CLUSTER_NAME to m5.2xlarge:

$ oc patch machineset CLUSTER_NAME –type=’merge’ –patch='{“spec”: { “template”: { “spec”: { “providerSpec”: { “value”: { “instanceType”: “m5.2xlarge”}}}}}}’ -n openshift-machine-api

Scale down CLUSTER_NAME to zero:

$ oc scale machineset CLUSTER_NAME –replicas=0 -n openshift-machine-api

Scale back up the CLUSTER_NAME to 1 again:

$ oc scale machineset CLUSTER_NAME –replicas=1 -n openshift-machine-api

In this instance, CLUSTER_NAME is the name of one of your cluster (or worker) nodes. You can repeat the command for all of your worker nodes. Run the first command ( oc get machinesets ) to see a listing of all of your worker nodes, as shown in Figure 2.

Figure 2: View a listing of all of your worker nodes.

Step 2: Create a new OpenShift project namespace

If you install ACM through the OpenShift OperatorHub, a new OpenShift project will be created automatically. However, I recommended creating the new OpenShift project namespace before you install ACM. The images required to deploy ACM to OpenShift are hosted in remote registries, so you can still anticipate the additional authentication issue. By providing the authentication you know for sure it works, you can ensure that the image pull error will be avoided and will work successfully. Also, among other things, creating the OpenShift project first will allow you to create an image-pull secret before you install ACM.

Note: If you are installing ACM in a restricted environment, it is especially important to create a new OpenShift project before installing ACM. Doing so will help you avoid errors in the installation process.

To create a new OpenShift project in the CLI, you need to create a new namespace and then switch to the project. For this example, run the following command to create a new OpenShift namespace named open-cluster-management:

$ oc new-project open-cluster-management

Then, run the following command to switch to the project:

$ oc project open-cluster-management

Step 3: Create an image-pull secret

While the ACM Operator is capable of determining the required credentials to pull images from the Red Hat Registry, I recommend creating the image-pull secret yourself. There are two reasons:

Manually creating the image-pull secret eliminates a potential problem with authenticating the image pull. If you end up working in a restricted environment, you will have to pull the ACM images from a private image registry instead of the Red Hat Registry.

To create a new OpenShift secret in the CLI, use the following command to create a new OpenShift secret that will authenticate with the Red Hat Tech Preview Registry, where ACM is hosted:

$ oc create secret docker-registry YOUR_SECRET_NAME –docker-server=registry.access.redhat.com/rhacm1-tech-preview –docker-username=YOUR_REDHAT_USERNAME –docker-password=YOUR_REDHAT_PASSWORD

For YOUR_SECRET_NAME , provide the OpenShift secret name that you will use to pull the images from the Red Hat Registry. This name is used when you create the MultiClusterHub later. For YOUR_REDHAT_USERNAME and YOUR_REDHAT_PASSWORD , use the credentials for your Red Hat subscription.

Step 4: Install ACM and subscribe to the ACM Operator group

In this section, I will show you how to install ACM and subscribe to the ACM Operator group using both the CLI and the OpenShift web console.

Install and subscribe using the CLI

If you are using the CLI, you will need to manually create an ACM Operator group before you can subscribe to it. To start, create a YAML file named acm-operator.yaml :

apiVersion: operators.coreos.com/v1 kind: OperatorGroup metadata: name: acm-operator spec: targetNamespaces: – open-cluster-management

In this case, acm-operator is the name of Operator group that you want to call, and open-cluster-management is the name of the OpenShift project that you created in Step 2.

You can now run the following command to apply the OperatorGroup that you have just created:

$ oc apply -f acm-operator.yaml

Next, create another YAML file for an ACM subscription. I am calling the subscription file acm-subscription.yaml :

apiVersion: operators.coreos.com/v1alpha1 kind: Subscription metadata: name: acm-operator-subscription spec: sourceNamespace: openshift-marketplace source: redhat-operators channel: release-1.0 installPlanApproval: Automatic name: advanced-cluster-management

Run the following command to install the subscription:

$ oc apply -f acm-subscription.yaml

Install ACM and subscribe using the OpenShift web console

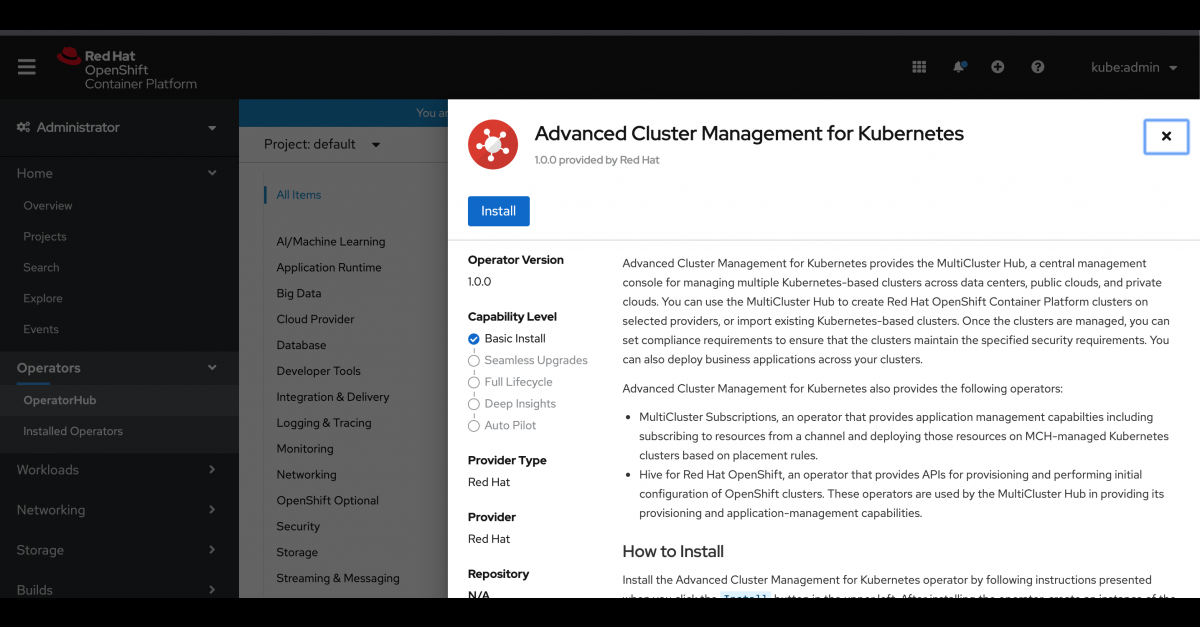

To install and subscribe to the ACM Operator group from the OpenShift web console, the first thing you need to do is open the web console and select the OperatorHub. Search for “advanced cluster,” and Advanced Cluster Management for Kubernetes will pop up. Select it, as shown in Figure 2.

Figure 2: Searching for ‘advanced cluster’ brings up Advanced Cluster Management for Kubernetes.

You will see a brief description of Advanced Cluster Management for Kubernetes. Click the Install button, as shown in Figure 3.

Figure 3: Install Advanced Cluster Management for Kubernetes.

Next, set up the ACM subscription. Choose the open-cluster-management OpenShift namespace that you created earlier. As shown in Figure 4, ACM will try to install this namespace as the default.

Figure 4: Create the Operator subscription with your project namespace as the default.

Once you’ve selected the namespace, scroll down, and click Subscribe, as shown in Figure 5.

Figure 5: Click Subscribe to complete the installation and subscription.

If you are still in the web console, you will see the ACM Operator installation taking place. If everything goes well, you will see the status shown in Figure 6.

Figure 6: The success page shows your installed Operators, including the ACM Operator.

If you click Advanced Cluster Management for Kubernetes in the web console at this point, you will not initially see much of anything. You must proceed with installing the MultiClusterHub to see the running ACM application.

Step 5: Create the MultiClusterHub resource

Again, I will walk you through how to create the MultiClusterHub through both the command line and the web console. Adding the MultiClusterHub Operator—which is defined and managed through a Custom Resource Definition (CRD)—lets you manage the cluster type, policy, monitoring, cluster topology, more.

Create the MultiClusterHub from the CLI

To install the MultiClusterHub using the command line, start by creating a YAML file called multicluster-acm.yaml :

apiVersion: operators.open-cluster-management.io/v1beta1 kind: MultiClusterHub metadata: name: multiclusterhub namespace: open-cluster-management spec: imagePullSecret: YOUR_SECRET_NAME

In this case, open-cluster-management is the OpenShift project name and YOUR_SECRET_NAME is the OpenShift secret that contains the image-pull secret that you created in Step 3.

Run the following command to install the MultiClusterHub:

$ oc apply -f multicluster-acm.yaml

Run this command to get the application URL, which you will use to access the application:

$ oc get route

Create the MultiClusterHub using the web console

Now, let’s follow the same steps using the web console. To start, open the ACM menu, then click the MultiClusterHub tab that is shown in Figure 7.

Figure 7: Open the MultiClusterHub tab.

From the MutiClusterHub section, click Create MultiClusterHub, as shown in Figure 8.

Figure 8: Create the MultiClusterHub.

Next, you’ll be asked to provide a value in the imagePullSecret field. Enter the OpenShift secret name that you created in Step 3, then click Create (as shown in Figure 9).

Figure 9: Enter the OpenShift secret name, then click Create.

Note: Some ACM users report that it is possible to leave the spec field shown in Figure 9 empty (as spec: {} ) and successfully install the MutiClusterHub. I recommend providing the OpenShift secret that you will use to pull the required ACM images, with the correct credentials.

Step 6: Verify the ACM installation

As the final step, let’s make sure that we have successfully installed ACM. First, confirm that the MultiClusterHub events log reports no issues in the web console, as shown in Figure 10.

Figure 10: Check the MultiClusterHub events log.

Next, check the pods to ensure that they are all running successfully, as shown in Figure 11.

Figure 11: Confirm that the pods are all running.

Note: There is a known problem with the mcmapi-server that occurs due to a cert-manager error. Execute oc get helmreleases , and then grep cert-manager to verify the version of cert-manager and correct it.

Finally, you can visit the ACM URL (which is exposed through the application route) to confirm the successful installation, as shown in Figure 12.

Figure 12: The ACM welcome page confirms the successful installation.

Conclusion

You can now install Advanced Cluster Management through Red Hat Openshift. Your next step is learning how to use these tools to manage multiple clusters. Next time, I will cover the ACM features and tricks that will get you there.

Aluminium composite panel. Everything you need to know

There is one thing we can all agree on within the construction industry, and it is that the popularity of aluminum composite panel has not stopped growing over the past few years. Its use has been expanding under the cover of energy efficiency, low price and construction possibilities.

This type of material is specially designed for the construction of ventilated facades, their renovation or rehabilitation. It provides solutions that can be adapted to all fields of architecture.

In this post you will know everything you need to know about the composite panel, how it is produced, its main characteristics, finishes, transformations and its most popular uses.

ALUMINIUM COMPOSITE PANEL, WHAT IS IT AND WHICH ARE ITS MAIN USES

How aluminium is obtained

Aluminum is the third most common element found in the earth’s crust. In its natural state it is found in many silicates, and is extracted from the mineral known as bauxite, a sedentary rock with a high aluminium content. As a metal, its low density and resistance to corrosion, in addition to being a good conductor, make it an extremely useful element for many industrial processes. Currently, with China leading the way as a producer, it is estimated that around 60,000 metric tons are produced annually, 20% of which are recycled

Main characteristics of aluminium

Among its usual uses, and it could looks incredible, is the manufacture of mirrors (thanks to its optical properties), containers and cans or, of course, as aluminum foil for domestic use. It has multiple standards of alloys that fit to sectors as diverse as the automotive industry, telephony or construction.

Aluminium can be easily combined with other materials to produce new materials such as those used in briks or in the composite panel.

Composition and elaboration of the aluminium composite panel

STACBOND composite panel is composed of two aluminium sheets and an inner thermoplastic base core that can hold mineral charge.It is specially designed for new construction ventilated facades as well as for renovation or rehabilitation. Its manufacturing standard is composed of an outer sheet of 5005 aluminium alloy and an inner sheet of 3105. It is divided into two groups depending on the mineral load of its core and can be incombustible or fireproof and (according to UNE 13501-1:2007) classified as A2-s1, d0 and B-s1, d0. The composite panel is produced by a continuous lamination process, in which a sheet of the material that will make up the core is extruded and compacted between two aluminium sheets that are unwound at the same time. Finally, the flatness of the material is compacted and perfected and a protective film is applied.

Uses of the aluminium composite panel

As I told you before, its most common use is in ventilated facades, a type of coating system in several layers that stands out for its effectiveness in solving the buildings insulation, thanks to the thermal behavior that the facade achieves. The most curious thing about the ventilated facade is that it allows the creation of a chimney effect between its layers. This chimmey generates a continuous ventilation in the chamber, maintaining a stable temperature that results in greater energy efficiency compared to more conventional systems. Thus, during the summer, the heat is evacuated and the circulating air is renewed. In winter, air circulation is slowed down, preserving the heat.

A versatile, recyclable and quick to install product

Since the aluminium composite panel began its journey in the construction sector, its characteristics have been improving until it has become a highly modifiable product, which admits different forms of assembly, colours, transformations and uses.

As an example of its great versatility, we can find it in both minor works and interiors, combined with other materials to cover certain areas of a facade or as the main element in complicated transformations.

Among its properties we find:

High dimensional stability As a material, the composite panel does not present deformations in its dimensioning, whic means that the material remains stable whatever its size without losing its properties A multitude of finishes The wide range of finishes that the composite panel allows gives it a great aesthetic versatility. From solid to textured, mirror or wood type finishes, the composite panel can be adapted to almost any type of project Impact resistant Recent studies confirm the durability of aluminium in building facades due to its long life and resistance to wear and corrosion Fully recyclable The core material and cover sheets of aluminum composite panel can be recycled and reused. Due to its characteristics, aluminium can be recycled indefinitely Quick and easy assembly The hanging systems for the assembly of aluminium composite panels are designed to facilitate their assembly on facades in a quick and easy way. In the same way, in case that a cassette is damaged, it is easily replaceable Light as a feather The low density of aluminium makes it the ideal material for substructure systems on ventilated facades

CUSTOMISED FINISHES

How to paint the composite panel

Depending on the finish that is sought, the panel can receive multiple types of treatments and coats. Among the most common finishing paints there are:

PVDF (Fluorinated polyvinyl) It is the most popular finish for architectural applications. In a 70/30 proportion of resin it has a higher folding capacity, as well as a better resistance to ageing and protection against UV rays. FEVE (Lumiflon) FEVE is a type of coating with a very similar structure to PVDF, but with greater hardness and less flexibility. It allows to achieving a greater gloss range. HDPE (High Durability Polyester) HDPE paint, on the other hand, allows a high range of gloss and some special finishes such as textured surfaces.

Solid, metallic and special finishes

The aluminium composite panel allows a large number of different finishes. In addition, it can be adapted to any colour from the RAL colour chart. Over time, special finishes have been added with texture effects, imitating wood or concrete, or iridescent with special lighting effects.

Solid and metallic colors The solid finishes are homogeneous and hardly suffer the variation of their tonality with the incidence of light. They provide a sensation of solidity to the facade and are easily combined with other finishes. Metallic colours, very similar to those used in the automotive sector, vary their shade with respect to the incidence of sunlight and are very popular for large facades and outstanding projects. Other special finishes Textured effects, matte or high-gloss surfaces, iridescent and wood finishes are some of the special finishes. To them we are constantly adding the new technology advances.

IMPOSSIBLE SHAPES

Currently, aluminum composite panel can be transformed in many ways. Among them are punching, which allows the creation of pointy-type shapes on the surface of the panel, creating drawings or forms; roller bending, to achieve curved shapes; CNC stamping and engraving to create reliefs; 3D shaping to project volumes on a flat surface, etc. This transformation capacity of the aluminium composite panel gives it a plus of versatility in order to being used for constructing risky and creative designs. It also makes it an ideal material to combine and make the areas of the facade which would be impossible with other kind of materials. Beyond the usual picture of a ventilated flat facade, we see how the panel can be used for other more striking projects and risky designs that contribute to give a special character to the buildings.

Let’s see it in a little more detail:

Punching and die-cutting The composite panel can be punched and die-cut with CNC. The result ranges from the creation of pointillist or artistic style patterns to complicated and detailed drawings on the facade Edging There are three types of edging: Simple, which hides the edging Double interior, hides the edge and part of the back Double outside, hides the edge and extends a flange that hides the joints with other panel sheets.

Roller bending The panel can be easily bent following the minimum necessary bending radii. To do it, it is best to use bending machines with 3/4 rolls. By bending the product, columns can be covered, concealing the corners with a rounded appearance, etc. Stamping and engraving With more limitations than the previous transformations, we find that in the panel, through modifications in its depth, it is possible to make engravings creating forms without having to get to cut-die the panel

3D Forming The 3D forming process, besides of being used to manufacturing aluminium composite panel for hanging systems, can also be used to create projected three-dimensional surfaces Milling The milling of the panel gives results that differ from other types of processing such as punching and, of course, from the usual conception of the composite panel as a cassette-type tray. It can be made with CNC, with a wall saw or a portable one. The partial milling of the panel allows the subsequent folding of the pieces to give them creative shapes

RESISTENT PANELS

Depending on the composition of the interior mineral core of the composite panel, it will have some proper characteristics. For example, it will have a greater resistance in case of fire or a special malleability, a very useful aspect when making creative transformations of the facade.

As has happened with the types of finish, as technology is moving forward, the composite panel has also developed new mineral cores that give it special resistance and make it more adaptable to what conditions.

Composite panel types

FR The FR (Fire Retardant) type panel, on the other hand, contains an interior fire retardant core made of thermoplastic resins with mineral charge. Its reaction to fire classification B-s1, d0 (according to UNE EN 13501-1:2007), makes it a coating material that fulfils most of the architectural applications

How to Install Aluminum Cladding

Step 1

Snap a chalk line level at least 8 inches above the ground and fasten a metal starter strip with aluminum nails with large heads every 6 inches. Place nails in the center of the nailing slots and do not drive completely in; aluminum expands and contracts and needs space to move slightly. Nail J-channel posts at the corners for the panels to fit into. Nail every 12 inches making sure they are plumb.

Step 2

Push the first panel firmly up into the starter strip and nail to wall studs through slots on the top. Slide it into the J channel at the corner, leaving 1/8 inch for expansion. Start at the back of the wall, so panels overlap with the front one on top, to provide a more finished look. Add panels, slipping the bottom of each new panel into the slot at the top of the previous panel to lock it, then nailing the top in the nail slots. Nail in the center of the slots and don’t drive nails in fully. Stagger seams, cutting panels with tin snips or a metal saw if necessary to avoid having seams match.

Step 3

Install door and window trim at those openings, first caulking around openings to make sure they are water and air tight. Nail on top trim first, then the sides and then, for windows, the bottom. Nail the trim every 12 inches; on sides, nail at the top of the first vertical nailing slot, then in the center of others down the strip. Slip siding panels into these trim pieces as you reach them. Trim panels with tin snips or metal saw to fit the door and window trims, leaving 1/8-inch for expansion. Put gutter seal adhesive on panels under window sills.

Step 4

Install F channel trim at the top of the wall. This is similar to J channel but is designed to secure the tops of the wall panels. The panels will slip into the F channel to secure them. Measure and cut the panels to fit, leaving 1/8 inch for expansion, before putting them into place.

So you have finished reading the how to install aluminum cladding topic article, if you find this article useful, please share it. Thank you very much. See more: ALUCOBOND, Facade stone cladding, Alucobond Vietnam, vinyl siding overlap direction, can you put new vinyl siding over old vinyl siding, can you bend vinyl siding, curved siding, vinyl siding curved wall