You are looking for information, articles, knowledge about the topic nail salons open on sunday near me how to make spline shaft on Google, you do not find the information you need! Here are the best content compiled and compiled by the https://chewathai27.com team, along with other related topics such as: how to make spline shaft spline shaft standard sizes, spline shaft suppliers, how to make female splines, involute spline shaft, spline shaft design, spline shaft design pdf, spline shaft coupling, spline shaft design calculation

Contents

How are splines manufactured?

Spline cutting is the process carried out internally and externally. In internal splines broaching and slotting operations are carried out and at the same time external splines can be manufactured by the process of hobbing, milling and shaping.

What is the base diameter of a spline?

The path that the end of the string would make as the string is unwound is called an involute curve (fig. 3). The unmovable diameter is called the Base Diameter. The base diameter is a relation between the pitch diameter and the pressure angle (base diameter = pitch diameter x the cosine of the pressure angle).

What are the types of splines?

There are numerous types of spline shafts, including, involute splines, which have short, curved, and evenly spaced teeth; parallel splines, which are short, straight sided splines; serrated splines, which are V shaped; and helical splines, which are built for optimal load sharing.

How do you make a shaft?

The most common process used to manufacture shafts is via CNC turning. Using this technique, workers or automated processes affix or clamp bars of materials to chucks and rotate them. While rotating, specialized tools use cutting and other subtractive processes to create and shape the end product.

Which industry widely used splines shafts?

Splined shafts are critical to a broad range of applications, from manufacturing and industrial facilities to public transportation, automobiles, and aerospace equipment. Splined shafts are capable of transmitting torque for high speed applications and heavy-duty load bearing equipment.

What is spline broaching?

Spline broaching involves using a broach to form a series of ridges or teeth around the circumference of a pre-cut hole. It is an efficient way to create serrated, straight or involute splines. The automotive industry relies on spline broaches to create transmission and driveshaft parts, among other items.

How are internal splines cut?

The splines are cut into the shaft by a process called straddle milling. The indexing fixture holds the shaft of the spline steady while a groove is cut by the rotating milling cutters along its length. Depending on the depth of the spline, multiple passes along the same groove may be needed.

How do you read a spline size?

Typical involute SAE/ANSI spline teeth are specifies as two numbers: a numerator that specifies the tooth thickness in diametral pitch (DP) and the second number that specified the tooth height in diametral pitch (DP). Thus an 8/16 spline has the tooth thickness of 8 DP and a tooth height (whole depth) of 16 DP.

What is a helical spline?

A helical spline broach — also known as a spiral broach or continuous engagement broach — is a type of broach that creates an internal spiral in a pre-drilled hole. Several applications use helical spline broaches, including automotive transmission and firearms manufacturing.

How do you create a shaft spline in Solidworks?

- Click 3D Sketch. (Sketch toolbar) or Insert > 3D Sketch.

- Click Spline. …

- Click to place the first spline point, then drag to sketch the spline. …

- Continue to place spline points and change planes if necessary.

- When the spline is complete, double-click to stop sketching.

What is splined shaft?

Definition of spline shaft

: a splined shaft specifically : one having a number of equally spaced grooves cut in the shaft so as to form a series of projecting keys and fitting into an internally grooved cylindrical member.

How do you read a spline size?

Typical involute SAE/ANSI spline teeth are specifies as two numbers: a numerator that specifies the tooth thickness in diametral pitch (DP) and the second number that specified the tooth height in diametral pitch (DP). Thus an 8/16 spline has the tooth thickness of 8 DP and a tooth height (whole depth) of 16 DP.

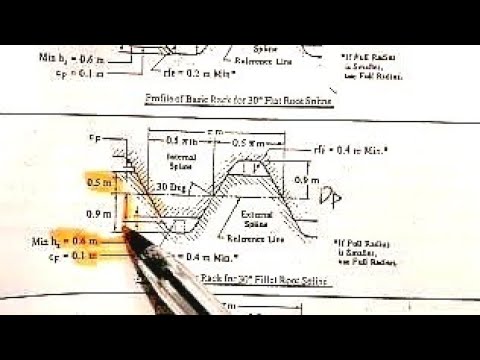

Spline shaft design. – YouTube

- Article author: www.youtube.com

- Reviews from users: 26141

Ratings

- Top rated: 4.2

- Lowest rated: 1

- Summary of article content: Articles about Spline shaft design. – YouTube Updating …

- Most searched keywords: Whether you are looking for Spline shaft design. – YouTube Updating Spline shafts are widely used in the agricultural industry, trucking industry and where large torque requirements is a must. This is one of the many methods …video, chia sẻ, điện thoại có máy ảnh, điện thoại quay video, miễn phí, tải lên

- Table of Contents:

how to make spline shaft

- Article author: www.ijlera.com

- Reviews from users: 34918

Ratings

- Top rated: 4.7

- Lowest rated: 1

- Summary of article content: Articles about how to make spline shaft Updating …

- Most searched keywords: Whether you are looking for how to make spline shaft Updating

- Table of Contents:

CUT PTO SPLINES IN 18 EASY STEPS! – YouTube

- Article author: www.youtube.com

- Reviews from users: 24203

Ratings

- Top rated: 4.0

- Lowest rated: 1

- Summary of article content: Articles about CUT PTO SPLINES IN 18 EASY STEPS! – YouTube Updating …

- Most searched keywords: Whether you are looking for CUT PTO SPLINES IN 18 EASY STEPS! – YouTube Updating Ever cut a PTO spline before? I haven’t. Know what else I’ve never done? Bought the correct cutter to do the job. :(Music: “TipToes” – MyuuPTO, spline, cutting splines, dividing head, parallel splines, mill, lathe, milling machine, home shop machining

- Table of Contents:

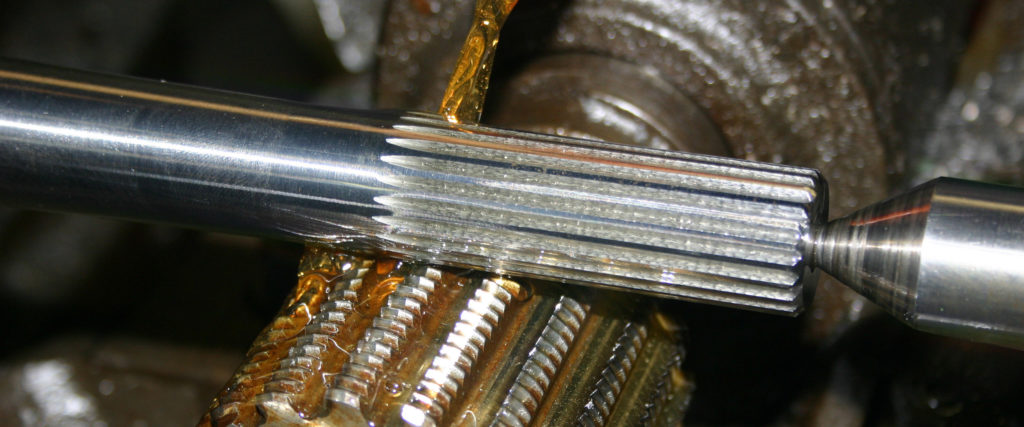

Spline, Worm and Gear Hobbing – How to Make Gears – YouTube

- Article author: www.youtube.com

- Reviews from users: 26437

Ratings

- Top rated: 3.9

- Lowest rated: 1

- Summary of article content: Articles about Spline, Worm and Gear Hobbing – How to Make Gears – YouTube Updating …

- Most searched keywords: Whether you are looking for Spline, Worm and Gear Hobbing – How to Make Gears – YouTube Updating Quick overview about the production methods of gear cutting. This video illustrates the basic generating methods of a hobbing machine.The first spline is a 1…Gear (Product Category), gear manufacturing, gear production, involute spline, gear cutting, Worm Gear, Helical Gear, Serration hobbing, Hobbing, Gear Hobbing, Gear Generation, spline hobbing, Spline, Manufacturing (Industry)

- Table of Contents:

How to Manufacture Splined Shafts?

- Article author: true-gear.com

- Reviews from users: 15227

Ratings

- Top rated: 4.4

- Lowest rated: 1

- Summary of article content: Articles about How to Manufacture Splined Shafts? Another method that can produce internal splines is slotting. The cutting tool moves up and down as it feeds into the workpiece. Upon reaching … …

- Most searched keywords: Whether you are looking for How to Manufacture Splined Shafts? Another method that can produce internal splines is slotting. The cutting tool moves up and down as it feeds into the workpiece. Upon reaching … Internal splines with slots or gaps mesh with similarly spaced teeth on a splined shaft to transmit torque. This video shows you how to mill a splined shaft.

- Table of Contents:

General | Making a spline shaft | Practical Machinist – Largest Manufacturing Technology Forum on the Web

- Article author: www.practicalmachinist.com

- Reviews from users: 24978

Ratings

- Top rated: 4.2

- Lowest rated: 1

- Summary of article content: Articles about General | Making a spline shaft | Practical Machinist – Largest Manufacturing Technology Forum on the Web The process I used is as follows: Center the cutter on the se of shaft. Lower the cutter so that the top of the cutter cuts the bottom of the … …

- Most searched keywords: Whether you are looking for General | Making a spline shaft | Practical Machinist – Largest Manufacturing Technology Forum on the Web The process I used is as follows: Center the cutter on the se of shaft. Lower the cutter so that the top of the cutter cuts the bottom of the … I have a shaft that is 16-spline fitting straight 2in Dia and I am looking for the tool. I have never speced tooling for a shaft like this so I was…

- Table of Contents:

The Beginner Guide To Splined Shaft – DEK Manufacturing

- Article author: www.dekmake.com

- Reviews from users: 9889

Ratings

- Top rated: 4.2

- Lowest rated: 1

- Summary of article content: Articles about The Beginner Guide To Splined Shaft – DEK Manufacturing Splined shafts can easily handle high rotation speeds and deliver torque. It is easy for splined shafts to deliver more torque than other shafts … …

- Most searched keywords: Whether you are looking for The Beginner Guide To Splined Shaft – DEK Manufacturing Splined shafts can easily handle high rotation speeds and deliver torque. It is easy for splined shafts to deliver more torque than other shafts … Are you looking for an ultimate and complete guide that can help you know all the minor and major details of the splined shaft? You have landed at the right

- Table of Contents:

What is a splined shaft

What is the function of the splined shaft

What are the applications of the splined shaft

What is the construction of a splined shaft

What materials can be made of the splined shaft

How to use a splined shaft

How to clean the splined shaft

Can you offer a custom splined shaft

Summary

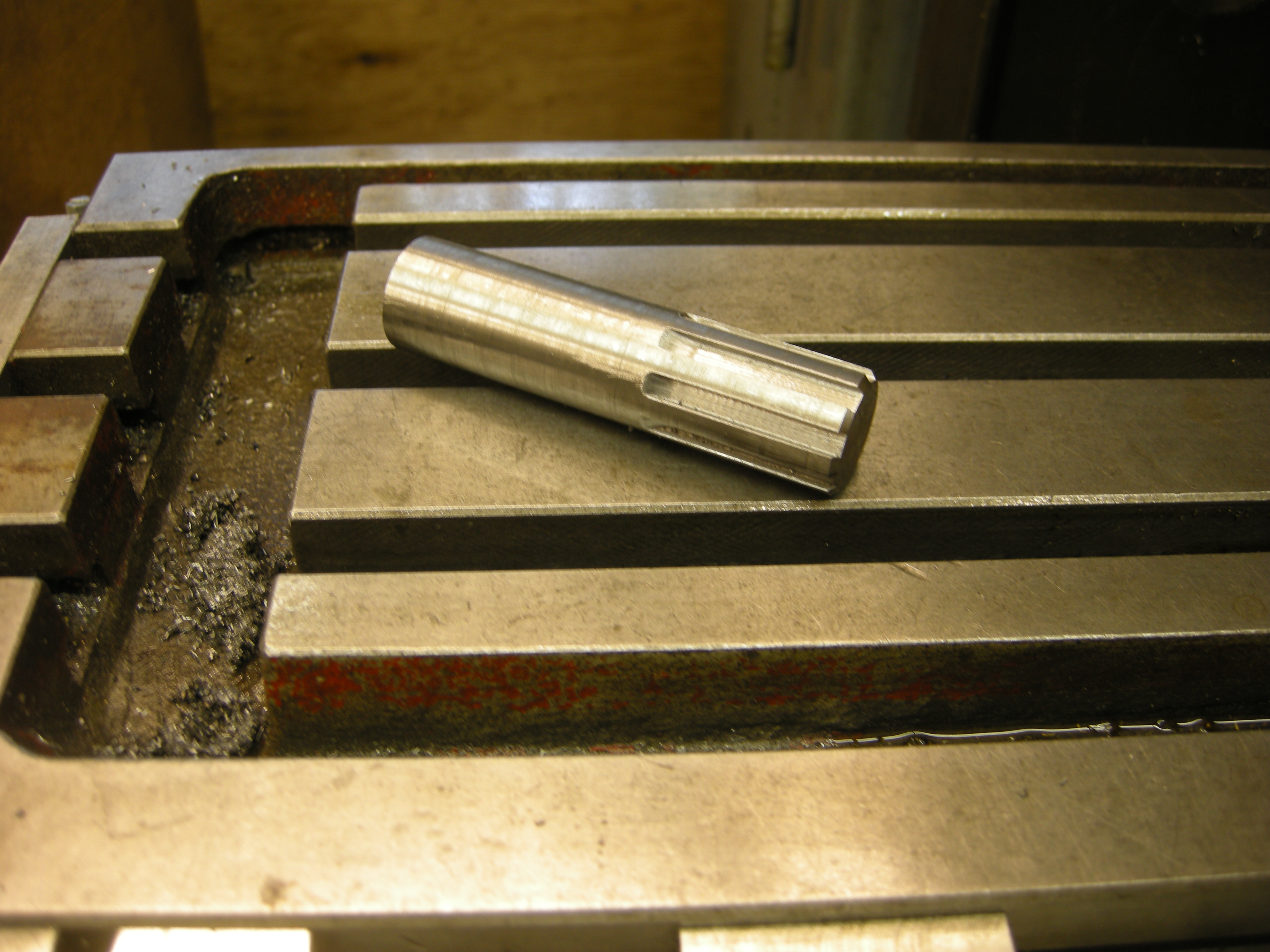

Milling machine – how to make – splines | john f’s workshop

- Article author: johnfsworkshop.org

- Reviews from users: 5458

Ratings

- Top rated: 4.0

- Lowest rated: 1

- Summary of article content: Articles about Milling machine – how to make – splines | john f’s workshop A spline is commonly taken to mean a series of grooves cut in a shaft equally spaced around its circumference. A male spline is designed to fit into a female … …

- Most searched keywords: Whether you are looking for Milling machine – how to make – splines | john f’s workshop A spline is commonly taken to mean a series of grooves cut in a shaft equally spaced around its circumference. A male spline is designed to fit into a female … go to the home page go to the page above this one Milling machine – making – splines A spline is commonly taken to mean a series of grooves cut in a shaft equally spaced around its circumference. A male spline is designed to fit into a female spline. This has several advantages. There can…

- Table of Contents:

model engineering

Milling machine – making – splines

US6336351B1 – Method of manufacturing spline shaft

– Google Patents

- Article author: patents.google.com

- Reviews from users: 32909

Ratings

- Top rated: 3.8

- Lowest rated: 1

- Summary of article content: Articles about US6336351B1 – Method of manufacturing spline shaft

– Google Patents A method of manufacturing a spline shaft, comprising ironing a hollow stock by cold forging and forming splines in a desired portion of sa hollow stock by … … - Most searched keywords: Whether you are looking for US6336351B1 – Method of manufacturing spline shaft

– Google Patents A method of manufacturing a spline shaft, comprising ironing a hollow stock by cold forging and forming splines in a desired portion of sa hollow stock by …

A method of manufacturing a spline shaft, comprising ironing a hollow stock by cold forging and forming splines in a desired portion of said hollow stock by cold forging by using its work harden state. This method makes it possible to reduce the weight of a product by using a hollow stock, and to prevent buckling of the material of the hollow stock during the formation of splines owing to work-hardening caused by the ironing. Further, a predetermined root strength can be ensured without requiring induction hardening. Accordingly, a reduction in weight is achieved, and the production speed and yield are improved. - Table of Contents:

Info

Links

Images

Classifications

Abstract

Description

Claims (4)

Priority Applications (2)

Publications (1)

ID=14017814

Family Applications (1)

Country Status (2)

Cited By (2)

Families Citing this family (3)

Citations (7)

Family Cites Families (4)

Patent Citations (7)

Non-Patent Citations (1)

Cited By (4)

Also Published As

Similar Documents

Legal Events

– Google Patents

Inside Splines | Gear Solutions Magazine Your Resource to the Gear Industry

- Article author: gearsolutions.com

- Reviews from users: 8139

Ratings

- Top rated: 4.2

- Lowest rated: 1

- Summary of article content: Articles about Inside Splines | Gear Solutions Magazine Your Resource to the Gear Industry The externally splined shaft mates with an internal spline that … Broaching: This method is used to produce female splines of all types. …

- Most searched keywords: Whether you are looking for Inside Splines | Gear Solutions Magazine Your Resource to the Gear Industry The externally splined shaft mates with an internal spline that … Broaching: This method is used to produce female splines of all types.

- Table of Contents:

See more articles in the same category here: 670+ tips for you.

Making a spline shaft

HuFlung’s method works but I think too much trouble for one part.

First thing is, what does the mating part look like ? is it as butchered as the photo ? You need a good mating part to use as a go-nogo.

I use a slitting saw or horizontal milling cutter to knock out most of the material. Then grind a short piece of hss to fit the space – there’s enough of an unworn area on your part to do that. Braze it onto the end of a 6″ long piece of 3/4″ round steel. Cutting edge of the hss through a line radial through the center of your 3/4″ shank. You can do this by eye pretty easy.

Stick ‘er in the bridgeport and whale away. If you’ve got oversize collets for the bridgeport go to a 1″ shank. Rigidity counts.

Flange mics are easiest to use for measuring. Sides of the splines should be parallel and straight and centered but it’s not that hard to do. Dividing head.

Your part is o.d. fit. 95% of straight-sided splines are. The ones that are minor diameter fit you can tell because the roots are ground. Side fit is generally for involutes and doesn’t matter much anyhow, when you get the part to slide nice in your mating gage-part, the side fit / major dia fit question will take care of itself.

If you are going to make parts for a 747 things are more complicated but for this repair stuff, just make it fit and it’ll be fine.

The Beginner Guide To Splined Shaft

Are you looking for an ultimate and complete guide that can help you know all the minor and major details of the splined shaft? You have landed at the right place. This guide will tell you everything you need to know about the splined shafts. From the function to applications and production, every detail is given here.

What is a splined shaft?

A spline is a ridge or teeth that mesh with the groove and transfer the torque. It maintains the angular correspondence between the tracks and the shaft. A splined shaft can be defined as a shaft with several grooves cut in the shaft. All these grooves are equally spaced around the circumference, and they form a series of projecting keys. They give the shaft a shape that helps it fit into an internally grooved cylindrical member.

A spline shaft is a mechanical component that can perform various functions. It can work as an anti-rotational device, and at the same time, you can use it to transmit torque to any other device. It is used in various industries. There are many types of alternative shafts like the key shafts, but the splined shafts are the most convenient way to transfer the torque.

What is the function of the splined shaft?

The most common function of the spline shaft is to act as an anti-rotatory device. This function appears to be happening when working in the linear guide positions. If it is not working as a linear guard, the spline shaft works to transmit torque to another device. The function of the splined post is varied depending upon certain factors.

The spline shaft functions to mate with the female version and interlock to transfer the rotatory movement. The splined shaft works as a linear guide when coupled with a bearing with an internal spline gear mechanism. The function of a spline shaft depends upon the construction and type of spline applied to the shaft.

The functions of a typical spline shaft are often undertaken. It is because the splines of the gear are processed into the length of the post. There are different spline designs and shapes, and they have different roles and functions when mesh with the shaft.

What are the applications of the splined shaft?

Splined shafts are needed in several applications. They include manufacturing, locomotives, industrial facilities, automobiles, and many others.

Its most common application is in the automobile industry, aviation, and earth-moving machinery. The splined shafts are used at several places.

Splined shafts can easily handle high rotation speeds and deliver torque. It is easy for splined shafts to deliver more torque than other shafts because of their structure. The splined shafts have an equal distribution of load across every teeth or groove.

Spline shafts are very crucial for the production of many items as well as machinery in many industries. A splined shaft helps provide a uniform and controlled torque. It can also reduce the chances of misalignment with the parts.

What is the construction of a splined shaft?

The materials used in the splined shafts is very sturdy because it has to reduce deflection. The deflection and bending tooth profile start to distort with time. The materials for splined shafts are different metals, non-metals, and other materials. These materials include bronze, brass, stainless steel, titanium, Delrin, nylon, and steel alloys.

A spline is defined as a strip of wood, plywood, or some other materials. This strip is inserted into the grooves along the edges of the boards. Moreover, the ends of the splines are set to avoid stress as much as they can. Splined shafts are occupied in a massive variety of lengths and diameters, materials and types of grooves.

One thing that is focused on in the construction of a splined shaft is the load capacity. The capacity must be enough to carry the force across the axis so it can transfer the torque. The load capacity should be perfectly balanced; it should be neither too much nor too light. The use of high-quality material in the splined shaft, so the machines work properly.

What materials can be made of the splined shaft?

Splined shafts are made from different materials. The metals used in the manufacturing of the splined shaft are selected by checking for localized stress between the grooves of the shaft. Some of the materials are common in every splined shaft. These are as follows:

Stainless steel

Stainless steel is the alloy that contains chromium or nickel additions in the steel. It is highly wear-resistant and exceptionally durable. In splined shafts, stainless steel is the best option to provide tensile strength and prevents corrosion.

Carbon steel

Carbon steel is best known for its malleability, the property that lets the material be used and hammered into sheets. The carbon content of the carbon steel is shallow, nearly 1.7%.

In splined shaft engineering, carbon steel is used because of its valuable properties. The spline shaft having high-quality carbon steel helps to provide a reliable and smooth motion.

Alloy steels

The ferrous alloys of steel contain iron, carbon, nickel, chromium, and molybdenum. The alloys are used in splined shafts, and each one of them plays its part with its properties. The alloys include high-strength low-alloy steels, managing steels, harden-able high-alloy steels, and many other special alloy sheets of steel.

Aluminum alloys

Aluminum alloys are very useful in splined shafts. Aluminum alloys have less density than steel alloys, almost half of them. They provide more toughness at even moderate strengths. Aluminum alloys are very much resistant to corrosion.

How to use a splined shaft?

Splined shafts are used in various vehicles. Different designs of the post are responsible for different kinds of use. Following are some kinds and their services.

Crowded

This type of splined shaft has modified splines that become narrow as we move towards the end face. This splined shaft produces angular misalignment on the surface.

Parallel key

The parallel key in the splined shafts has separate profiles and ridges. They can be cut or cold roll-formed. This kind of splined shaft finds its uses in places where accuracy, high strength, and smooth finish in needed.

Involute

This type of splined shaft has been designed with tapered ridges. Its uses are found in the functions where stress concentrations need to be reduced. They help in preventing any movement between the internal and external parts. It is specifically helpful in the transmission of torque.

Helical

This type of splined shaft design is made with an involute spline. It can also be made from the parallel spline. The teeth or ridges in this spline make a spiral pattern. The most crucial use of helical pattern is that it allows both linear and rotatory motion.

Serrations

Serrations are designed at such an angle that they allow many teeth on the shaft with a relatively more minor diameter shaft. Serrations have straight flanks, but their grades are adjusted. The most significant advantage of serrations is the hub resulting in the splines that are self-centered. In the serrated splines, there are linear contacts and wears. The angles are set to provide maximum advantages.

How to clean the splined shaft?

The life expectancy of the splined shafts depends upon the cleaning and lubrication of the shaft. Good lubrication is easily achieved by submerging the spline into the oil. The cleaning of the shafts is also necessary to improve their function.

The dirt on the splined shaft is removed easily with a damp cloth. The grim of the shaft should be adequately cleaned and dried with a towel. Although the material used in the manufacture of the splined shaft is rust-free, if there happens to be any rust on the surface of the shaft, you can remove it with vinegar. The teeth or grooves in the shaft and the holes should be thoroughly cleaned and checked. Any residue should not be left in the shaft. Make sure to be careful while cleaning the shaft. Any scratch or harsh cleansing can be damaging.

How to produce a splined shaft?

There are two types of spline shafts; internal and external. There are different methods of manufacturing these types of spline shafts. With some bit amendments, these methods are used by experts for both types. These methods include broaching, shaping, milling, threading, hobbing, grinding, and extrusion.

Broaching

Broaching is a process that uses a toothed tool to remove the material from any surface. The toothed tool is called a broach. Broaching is used despite being an expensive process because it can give precise machining for odd shapes. In the manufacture of spline shafts, external broaches are used. These are also called blind broaches. They are used to cut furrows on the surface of the material along the length of the shaft.

Shaping

Shaping is the traditional method used for gear cutting. The blank gear is rotated alongside a piece of incomplete equipment. A shaper is a tool used for cutting internal and external teeth. It is a simple, reliable, and general method for gear cutting.

Milling

Milling is the process that uses a milling cutter to remove material from the surface of a workpiece. A milling cutter is used in splines because it has multiple cutting points on its rotatory cutting tool. The milling cutter can move perpendicularly on a surface which helps in the cutting to occur on the circumference of the edge. Spline milling can be used for the transfer of power throughout a mechanical system.

Hobbing

Hobbing is a machining process used to cut splines. Hobbing is a relatively inexpensive process as compared to the other cutting splines. The surprising fact is that it is an accurate method, and hence it is used on a wide range. Hobbing is helpful for the manufacture of external spline shafts only. This method is not accessible for the internal spline shaft.

Rolling

In the process of rolling, some synchronized shapes are formed on different parts of the shaft. These shapes are mostly threaded and splined, which shorten the manufacturing cycle. As a result, the relative phase between the spline and thread remains stable during mass production.

Grinding

It is an abrasive machining process. It uses a grinding wheel as a cutting tool.

Grinding is a metal cutting process. It is commonly used to cut out the minor details on the surface. Grinding is used on various types of steel, so it is helpful in the manufacture of a splined shaft. Surface grinding helps in the grinding of materials of the post with a unique technique.

Extrusion

Extrusion helps in the creation of objects with a fixed cross-sectional profile. Extrusion can help tackle particular simple things more efficiently with a spline shaft rather than extruding them by hand. It is pretty helpful as it allows various options in a simple operation.

However, there are some accessibility restrictions due to which the methods of manufacture of internal splines are significantly less. Mostly the methods used for external shafting are applicable. Hobbing is not accessible, and hence you cannot use it to manufacture the internal shaft.

Can you offer a custom splined shaft?

Yes, the splined shafts can be customized at DEK. If you want the machines to work efficiently, you should select the right size and type of the splined post. We can customize the splined shafts for you.

We use the material with uncompromised quality. We have great expertise in our field. The grooves, as well as the spacing between them, are also altered according to your need. Welcome to contact our sales team to get more information.

Summary

The splined shafts have found uses in several industries. They are the machines that make the work easy. The manufacturing of these splined shafts does not even require some fancy materials. We can easily customize the shafts and their designs according to your need and taste. You can contact various websites that have high ratings and experience in this field. We would recommend you to go to the sites that use high-quality material and advanced technologies for precision. Their customer service and expertise should have their name.

Milling machine – how to make – splines

Milling machine – making – splines

A spline is commonly taken to mean a series of grooves cut in a shaft equally spaced around its circumference. A male spline is designed to fit into a female spline.

This has several advantages. There can be negligible play rotationally between the two shafts. This is probably the best method of joining two shafts so as to maximise the power that can be carried from one to the other. The use of splines also allows for one shaft to slide longitudinally against the other.

Examples

Splines are used in transmission systems of cars where, due to the up/down movement of the wheels the distance between two points in the transmission will vary.

fig a spline on a prop shaft

Splines are used to hold handles on leadscrews

fig spline on a leadscrew

Splines are used in gear boxes because the gears can be slid along a spline in order to change gear.

fig splines in a gear box

Making splines

As can be seen in the examples above splines can have grooves of many different forms and sizes.

For any spline there are two parts.. There is the external spline and the internal spline. External spline can often be cut using a milling machine. Internal splines usually need some sort of slottting mechanism.

Two easy examples are where the groove is a rectangular channel and where the groove is a V-shaped cut.

Fig. Spline 367

This spline has parallel sides to each groove. In industry a cutter would be used that gave the groove a round bottom. This would be to make the best use of the material in the shaft.

In the home workshop this is not so important and it is easier to use an ordinary side and face cutter. This gives the groove a flat bottom.

In order to get the best fit between the male and female parts the groove is not cut with an endmill because, with the sizes of grooves involved, a side and face cutter will give a more accurate groove in terms of size and straightness.

Fig. Spline for stub axle fitted with splined gear 411

A cutter like this can be used on a horizontal arbor or a stub arbor in the vertical socket. Another problem is that there is a limit as to how close to the chuck the cutter can get.

Fig. Cutting a spline on a horizontal milling machine 455

It is also possible to cut the groove using a T-slot or Woodruff cutter held in the vertical socket.

fig cutting a spline on a vertical milling machine

So you have finished reading the how to make spline shaft topic article, if you find this article useful, please share it. Thank you very much. See more: spline shaft standard sizes, spline shaft suppliers, how to make female splines, involute spline shaft, spline shaft design, spline shaft design pdf, spline shaft coupling, spline shaft design calculation