You are looking for information, articles, knowledge about the topic nail salons open on sunday near me how to remove moisture from plastic on Google, you do not find the information you need! Here are the best content compiled and compiled by the Chewathai27.com team, along with other related topics such as: how to remove moisture from plastic plastic resin drying guide, how to dry wet pvc resin, plastic material drying temperature pdf, material drying equipment, plastic resin dryers, used conair plastic dryers, drying temperature for hdpe, conair plastic processing equipment

Moisture / water absorption is the capacity of a plastic or a polymer to absorb moisture from its environment. Absorbed moisture sometimes acts as a plasticizer, reducing the glass transition temperature and strength of plastic (this is a reversible side effect).Plastic. Plastic is one of the easiest materials to paint on and has an average drying time of 30 minutes.While many food storage, preparation, and serving products are made from plastic, microwaving them can accelerate the release of harmful chemicals like BPA and phthalates. Therefore, unless the plastic product is deemed microwave safe, avoid microwaving it, and replace worn plastic containers with new ones.

…

- 1 Dehumidifying Dryers. Dehumidifying Dryers are designed to eliminate moisture in the plastic material before processing. …

- 2 Rotary Wheel Dryers. …

- 3 Low Pressure Dryers or Vacuum Dryers. …

- 4 Compressed Air Dryers. …

- 5 Hot Air Dryers.

Contents

What does moisture do to plastic?

Moisture / water absorption is the capacity of a plastic or a polymer to absorb moisture from its environment. Absorbed moisture sometimes acts as a plasticizer, reducing the glass transition temperature and strength of plastic (this is a reversible side effect).

How long does it take for plastic to dry?

Plastic. Plastic is one of the easiest materials to paint on and has an average drying time of 30 minutes.

Can you dry plastic in the microwave?

While many food storage, preparation, and serving products are made from plastic, microwaving them can accelerate the release of harmful chemicals like BPA and phthalates. Therefore, unless the plastic product is deemed microwave safe, avoid microwaving it, and replace worn plastic containers with new ones.

Can you dry plastic?

Dehumidifying or drying plastics in the processing phase is a vital part of injection molding. Drying plastic resin is used to minimize or eliminate complications that may be caused by too much moisture in a plastic material.

Can moisture pass through plastic?

Water, as a vapour, can pass through some plastic packaging considerably more easily than expected. It is one of the most damaging contaminants, since in the vast majority of pharmaceutical products the water content has to be accurately maintained.

Can plastic absorb moisture?

Moisture-absorbing plastics

Plastics absorb water to a limited degree. The degree of moisture absorption depends on the type of plastic and the ambient conditions such as temperature, humidity and contact time.

How can I make plastic dry faster?

You can use hot air blower to dry the product, oven heater or vacuum drying can also be used depending on hte type of polymer and its degradation characteristics.

How do you dry plastic containers?

Here’s what the TikTok claims: If you’re washing plastic containers, wait for the cycle to end, then open the door, hang a towel on the door so half of it hangs inside the dishwasher, then shut it. Leave the towel to absorb the excess steam, and you should end up with a fully dry rack.

Why does Tupperware stay wet?

Since your glass, metal, and ceramic dishes absorb and retain more heat during the dishwashing cycle, they can easily evaporate leftover water droplets. Plastic doesn’t get as hot, so the water droplets stay and never fully dries.

What happens if you microwave plastic?

According to the World Health Organization (WHO), microwaving food is generally safe. However, microwaving in plastic containers is associated with increased leaching — the transfer or leaking of chemicals into food. Note that even if a plastic container is labeled “microwave safe,” that simply means it won’t melt.

How long can you microwave plastic?

How long can you microwave plastic? An FDA-approved, BPA-free plastic containers made using Type 5 polypropylene have been tested for up to 240 hours in the microwave before being introduced into the market. So, you don’t need to worry about it getting melted fast.

What happens when plastic is heated?

Thermal Degradation – Plastic materials subjected to prolonged exposure to high temperatures will lose strength and toughness, becoming more prone to cracking, chipping, and breaking, at a rate in proportion to the temperature and time of exposure.

How do you dry plastic food containers?

Drying with a tea towel will prevent water spots forming on the plastic, but you should leave boxes out to thoroughly air-dry afterwards. Avoid applying the lid, as this can trap unwanted moisture and stale air. Alternatively, you can find out if your plastic boxes are dishwasher-safe.

Does plastic attract humidity?

Hygroscopic. These plastics have the quality of attracting and absorbing moisture from the air and storing that moisture internally within the molecular structure. A few of the well-known types of plastic that are hygroscopic include acrylic, PET, polyurethane, polycarbonate, and nylon.

Why does plastic absorb water?

They are materials that absorb moisture due to their chemical characteristics, such as polyamides, which in the presence of moisture form hydrogen bonds: undesirable before processing but necessary afterwards, since without hydrating the pieces they may become brittle.

Why is it important to consider water absorption when processing plastics?

Importance of Water Absorption – Plastics Processing & Properties. The water absorption data is important to understand the performance of the polymeric materials during processing e.g. injection molding as well as in water or humid environments to avoid premature moisture-related failures.

Why does resin prevent moisture?

As moisture leaves the resin, a desiccant material that is extremely hygroscopic absorbs the moisture and releases the remaining air into the ambient environment.

Drying of Polymer (including Dehumidifying Dryers, Rotary Wheel Dryers, Low Pressure Dryers, Vacuum Dryers)

- Article author: www.bpf.co.uk

- Reviews from users: 33512

Ratings

- Top rated: 3.2

- Lowest rated: 1

- Summary of article content: Articles about

Drying of Polymer (including Dehumidifying Dryers, Rotary Wheel Dryers, Low Pressure Dryers, Vacuum Dryers)

Updating … - Most searched keywords: Whether you are looking for

Drying of Polymer (including Dehumidifying Dryers, Rotary Wheel Dryers, Low Pressure Dryers, Vacuum Dryers)

Updating Most raw plastic material looks dry. However hygroscopic materials such as Polycarbonate, Nylon and PET to name just three, attract moisture from the surrounding air. Drying processes include Dehumidifying Dryers, Rotary Wheel Dryers, Low Pressure Dryers, Vacuum Dryers. - Table of Contents:

Moisture Absorption and the Stability of a Machined Polymer | AIP Precision Machining

- Article author: aipprecision.com

- Reviews from users: 18139

Ratings

- Top rated: 3.8

- Lowest rated: 1

- Summary of article content: Articles about Moisture Absorption and the Stability of a Machined Polymer | AIP Precision Machining Updating …

- Most searched keywords: Whether you are looking for Moisture Absorption and the Stability of a Machined Polymer | AIP Precision Machining Updating An informative blog on how moisture absorption affects the size and dimensions of machined polymers and composites.

- Table of Contents:

Plastics Machining and the Importance of Water Absorption

Plastics Processing and Properties

Tests to Measure Water Absorption of Plastics

Water Absorption Values for Common Polymers

Want to learn more about factors that contribute to effective CNC machining

How Long It Takes Spray Paint to Dry & How to Speed up the Process

- Article author: homelyville.com

- Reviews from users: 31415

Ratings

- Top rated: 3.7

- Lowest rated: 1

- Summary of article content: Articles about How Long It Takes Spray Paint to Dry & How to Speed up the Process Updating …

- Most searched keywords: Whether you are looking for How Long It Takes Spray Paint to Dry & How to Speed up the Process Updating If you touch a fresh coat of spray paint, you could ruin it. So, the question is how long does it take spray paint to dry, and how to speed up the process?

- Table of Contents:

How Long Does It Take Spray Paint to Dry

How to Speed up the Process

Other Factors That Contribute to Drying Time

Final Thoughts

What Causes High Humidity In a House Symptoms to Watch Out For

Best Lubricants for Sliding Glass Doors and Windows

Can You Microwave Plastic?

- Article author: www.healthline.com

- Reviews from users: 7526

Ratings

- Top rated: 4.0

- Lowest rated: 1

- Summary of article content: Articles about Can You Microwave Plastic? Updating …

- Most searched keywords: Whether you are looking for Can You Microwave Plastic? Updating Plastic is a synthetic or semi-synthetic material that’s durable, lightweight, and flexible. This article explains whether you can safely microwave plastic.can you microwave plastic

- Table of Contents:

Types of plastic

Is it safe to microwave plastic

Other ways to reduce your exposure to BPA and phthalates

The bottom line

The Importance of Drying Plastics: Plastic Part Making – Midstate Mold

- Article author: www.midstatemold.com

- Reviews from users: 13034

Ratings

- Top rated: 4.8

- Lowest rated: 1

- Summary of article content: Articles about The Importance of Drying Plastics: Plastic Part Making – Midstate Mold Updating …

- Most searched keywords: Whether you are looking for The Importance of Drying Plastics: Plastic Part Making – Midstate Mold Updating Drying plastics is one of the most important steps in the processing phase of plastic injection molding. See the advantages of drying plastic resins.

- Table of Contents:

Main navigation

Hygroscopic vs Non-Hygroscopic

Advantages of Drying Plastics

Footer

Midstate Mold & Engineering

The Injection Molding Process

Sign up for our Mail List

Correct drying of plastic granules – how to reduce moisture | Conveying, dosing, drying and storage of plastic materials

- Article author: labotek.com

- Reviews from users: 19229

Ratings

- Top rated: 4.0

- Lowest rated: 1

- Summary of article content: Articles about Correct drying of plastic granules – how to reduce moisture | Conveying, dosing, drying and storage of plastic materials Correct drying of plastic granules – how to reduce moisture … when using type-6 nylon, as this material can absorb up to 9.5% of its weight in moisture. …

- Most searched keywords: Whether you are looking for Correct drying of plastic granules – how to reduce moisture | Conveying, dosing, drying and storage of plastic materials Correct drying of plastic granules – how to reduce moisture … when using type-6 nylon, as this material can absorb up to 9.5% of its weight in moisture.

- Table of Contents:

WO2018158481A1 – Method for removing moisture from polymer pellets for plastic injection and extrusion

– Google Patents

- Article author: patents.google.com

- Reviews from users: 46963

Ratings

- Top rated: 4.1

- Lowest rated: 1

- Summary of article content: Articles about WO2018158481A1 – Method for removing moisture from polymer pellets for plastic injection and extrusion

– Google Patents The invention relates to a solution for reducing and removing moisture from plastic pellets by means of absorption and condensation, in which energy … … - Most searched keywords: Whether you are looking for WO2018158481A1 – Method for removing moisture from polymer pellets for plastic injection and extrusion

– Google Patents The invention relates to a solution for reducing and removing moisture from plastic pellets by means of absorption and condensation, in which energy …

The invention relates to a solution for reducing and removing moisture from plastic pellets by means of absorption and condensation, in which energy consumption is reduced and the process is simplified, making use of infrared wavelength efficiency, and comprising the following steps: 1. a supply phase using a dosing tank; 2. a distribution phase using a pellet levelling and dispensing device, a conveyor belt and a vibrating motor on the conveyor belt; 3. a moisture-removal phase using one or more infrared wave emitters disposed in parallel, a ventilated or cooled motor for a set of emitters, an air-recirculation passage for a set of emitters, an input temperature probe, an output temperature probe, and a moisture control probe; and 4. a discharge phase in which the material from which the moisture has been removed is discharged using a thermally-insulated collector tank. - Table of Contents:

Info

Links

Classifications

Abstract

Description

Claims

Priority Applications (2)

Applications Claiming Priority (3)

Publications (1)

ID=63370600

Family Applications (1)

Country Status (6)

Citations (6)

Family Cites Families (8)

Patent Citations (6)

Non-Patent Citations (1)

Also Published As

Similar Documents

Legal Events

– Google Patents

EPO – European publication server

- Article author: data.epo.org

- Reviews from users: 36263

Ratings

- Top rated: 3.2

- Lowest rated: 1

- Summary of article content: Articles about EPO – European publication server The invention relates to a solution for reducing and removing moisture from plastic pellets by means of absorption and condensation … …

- Most searched keywords: Whether you are looking for EPO – European publication server The invention relates to a solution for reducing and removing moisture from plastic pellets by means of absorption and condensation … patent documents, patent application, granted patents, patent database, patent publication, patent statistics, patent listings, unpublished patents, european patent office, epoEuropean publication server – the source of information on published patent applications and granted patents.

- Table of Contents:

EP3591323

Quick Navigation

About us

National offices

Service & support

Contact us

The EPO in social media

5 key points on how to dry plastic material –

- Article author: www.myplasticmold.com

- Reviews from users: 35021

Ratings

- Top rated: 3.7

- Lowest rated: 1

- Summary of article content: Articles about 5 key points on how to dry plastic material – 2, maximum moisture content, drying temperature and drying time technical requirements for plastic raw materials. Most plastics can absorb … …

- Most searched keywords: Whether you are looking for 5 key points on how to dry plastic material – 2, maximum moisture content, drying temperature and drying time technical requirements for plastic raw materials. Most plastics can absorb …

- Table of Contents:

how to remove moisture from plastic

- Article author: cdn2.hubspot.net

- Reviews from users: 1260

Ratings

- Top rated: 4.6

- Lowest rated: 1

- Summary of article content: Articles about how to remove moisture from plastic In other words, the materials absorb moisture in hum air condi- tions and release moisture in ar or dry condi- tions.Hygroscopic resins include PA, PC, PET, … …

- Most searched keywords: Whether you are looking for how to remove moisture from plastic In other words, the materials absorb moisture in hum air condi- tions and release moisture in ar or dry condi- tions.Hygroscopic resins include PA, PC, PET, …

- Table of Contents:

how to remove moisture from plastic

- Article author: www.mdpi.com

- Reviews from users: 37487

Ratings

- Top rated: 3.7

- Lowest rated: 1

- Summary of article content: Articles about how to remove moisture from plastic Abstract: Plastic materials can absorb moisture from the atmosphere even after drying. This absorbed moisture can cause many defects in the … …

- Most searched keywords: Whether you are looking for how to remove moisture from plastic Abstract: Plastic materials can absorb moisture from the atmosphere even after drying. This absorbed moisture can cause many defects in the …

- Table of Contents:

See more articles in the same category here: Top 122 tips update new.

Drying of Polymer (including Dehumidifying Dryers, Rotary Wheel Dryers, Low Pressure Dryers, Vacuum Dryers)

It should also be taken into account that over-drying of material, for too long or at too higher temperatures is also potentially disastrous. If colour pigments are being used over drying and too long residence time in the drying process can cause shifts in the colour, potentially causing it to darken.

So what are the options available to plastics processors to ensure that their raw material is in the optimum condition for processing? Contents 1 Dehumidifying Dryers

2 Rotary Wheel Dryers

3 Low Pressure Dryers or Vacuum Dryers

4 Compressed Air Dryers

5 Hot Air Dryers 1 Dehumidifying Dryers Dehumidifying Dryers are designed to eliminate moisture in the plastic material before processing. Air is forced through a desiccant bed to make it extremely dry. This air is then heated to a specified temperature and fed into a Drying Hopper containing the material to be dried. This hot dry air draws the moisture out of the material; the saturated air is then fed out of the Drying Hopper and back through the desiccant bed again to remove the moisture before the cycle begins again. This desiccant has a limited ability to hold moisture before it needs to be regenerated (dried out). Typically, plastics processors use regenerative or twin tower dryers and in this case, when the desiccant bed has reached its moisture retaining capacity the airflow is automatically switched to the second desiccant bed to allow the drying process to continue. At the same time, the first desiccant bed is regenerated by heating to remove moisture, allowed to cool and it is then ready to absorb moisture again. PMR0124 2 Rotary Wheel Dryers Rotary Wheel Dryers have been designed to address energy and other revenue draining issues presented by other types of drying. Rotor Dryers have a constant dew point whereas in twin desiccant dryers the dew point starts very low but increases as the desiccant bed saturates. When the airflow is switched to the second desiccant bed the dew point starts low again. Dew point control is a design feature of Rotor Dryers which allows the user to select a dew point suitable for the material to be processed and maintain this. This is a particularly beneficial feature as it virtually eliminates over drying. Some models of Rotor Dryers can save up to 40% in energy consumption when compared with the most efficient twin desiccant dryers, due to a lower regeneration temperature. This figure depends on the manufacturer of the dryer and can be less when only a 3-stage circuit technology is part of the design. 4 stage technology is available. Rotor Dryers utilise a rotating wheel which continuously puts dry desiccant into service due to its ability to regenerate moisture saturated desiccant in the same rotational cycle. Whereas the desiccant bed used in traditional Dehumidifying Dryers comprises desiccant beads and clay binder which degrades, Rotary Wheel Dryers employ in the region of 3 times the amount of pure desiccant. Desiccant beds on twin tower Dehumidifying Dryers regenerate at 320c, however in the Rotor Dryer it is an energy saving 140c. They do not use chilled water and they do not require compressed air.

Central Drying System 3 Low Pressure Dryers or Vacuum Dryers Low Pressure Dryers or Vacuum Dryers accelerate the plastic material drying process by using a vacuum to lower the boiling point of water from 100 °C to 56 °C. The moisture is rapidly extracted from the heated material. Leaving it in a condition to be moulded or extruded. Typically, these Low Pressure Dryers will dry materials in one-sixth of the time required by a desiccant dryer and the use of vacuum provides many process and revenue benefits when compared with conventional drying methods. This method of drying does not use desiccant at all and as such not only saves the expense but also saves the time required to maintain and replace desiccant. The low drying times offered by these machines reduces the risk of material degradation from exposing material to prolonged elevated drying times.

LPDs – Cleanroom Application 4 Compressed Air Dryers Compressed Air Dryers, compact and light in weight these Dryers are designed to fit to the throat of the processing machine, although a free standing frame can be employed. Generally a method of drying employed for smaller throughput machines, the Compressed Air Dryer is similarly equipped with twin desiccant beds as the Dehumidifying Dryer. The main difference between the two is that air flow is generated by compressed air instead of electrically driven mechanical blowers. 5 Hot Air Dryers Hot Air Dryers are designed to remove surface moisture from no-hygroscopic material and to pre-heat material prior to processing. This pre heating is particularly useful in circumstances where material has been stored outside in the cold and is brought into more warm and humid conditions for processing. They usually comprise a well insulated hopper with an attached blower and heater. Hot air is blown through the material granules and the wet air is dispelled into the atmosphere.

How Moisture Absorption Relates to the Stability of a Machined Polymer

Most polymers have a natural tendency to absorb water. In fact, some superabsorbent polymers are highly sought after in advanced applications for medical, construction and more. Yet, moisture absorption of thermoplastics leads to changes with regard to processing and properties.

It is crucial for machinists and designers to understand the moisture absorption of thermoplastics for CNC machining. During the design phase, this not only helps with initial material selection, but plays a role in predicting the life span of a part. At AIP, we take great care in providing unrivaled results to ensure the optimal dimensions and properties for machined polymers and composites. Join us in this technical brief as we give an in-depth explanation of the effects of moisture absorption for machined polymers.

Plastics Machining and the Importance of Water Absorption

Moisture / water absorption is the capacity of a plastic or a polymer to absorb moisture from its environment. Absorbed moisture sometimes acts as a plasticizer, reducing the glass transition temperature and strength of plastic (this is a reversible side effect). However, absorbed water also can lead to irreversible degradation of the polymer structure.

Some effects include:

Dimensional and mass changes (swelling) caused by water absorption

Extraction of water-soluble components

Changes in mechanical (elasticity, tensile strength, impact strength) and electrical performance

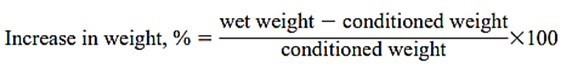

Water absorption is expressed as increase in weight percent or % weight gain of a plastic specimen under the following testing procedures:

Water Absorption 24 hrs at 23°C – Immersion of a plastic specimen in distilled water during 24 hours at 23°C

– Immersion of a plastic specimen in distilled water during 24 hours at 23°C Water Absorption 24 hrs at 100°C – Immersion of a plastic specimen in distilled boiling water during 24 hours Water Absorption at saturation – Immersion of a plastic specimen in distilled water at 23°C. Measurement occurs when the polymer does not absorb water anymore

– Immersion of a plastic specimen in distilled boiling water during 24 hours Water Absorption at saturation – Immersion of a plastic specimen in distilled water at 23°C. Measurement occurs when the polymer does not absorb water anymore Water Absorption at Equilibrium– Plastic specimen is exposed to a humid environment — generally at 50% relative humidity — at a specified temperature — 23°C or 73.4°F — for 24 hours

(Source: Omnexus)

Exposure to humidity, immersion and boiling water can result in different material responses. The equilibrium moisture content can be used to compare the amount of water absorbed by different types of plastics when they are exposed to moisture.

Plastics Processing and Properties

Polymers are affected by moisture from their environment or from simply sitting on a shelf waiting to be used. This is not a huge concern, but when the moisture absorption reaches more than 1% or 2%+, this can result in enough dimensional movement to create concerns.

Moisture Absorption Affects:

Mechanical properties

Wear properties

Dimensions

For example, parts made from TORLON (PAI) require special attention due to a 1.7% moisture at saturation value. While this number may not sound like much, it is enough to cause a precision machined TORLON part to exceed tolerance; in this scenario, the part cannot be used.

Therefore, it is important to properly package these mission critical polymers for lasting shelf-life and function. This can be achieved in two ways: 1) Vacuum-sealing them in a moisture-impermeable layer or 2) packaging them with bags of desiccant. This prevents moisture uptake in humid environments.

Tests to Measure Water Absorption of Plastics

ASTM D570 – Standard Test Method for Water Absorption of Plastics

This test method for rate of water absorption has two main functions:

A guide to the proportion of water absorbed by a material and consequently, in those cases where the relationships between moisture and electrical or mechanical properties, dimensions, or appearance have been determined, as a guide to the effects of exposure to water or humid conditions on such properties. A control test on the uniformity of a product. It is particularly applicable to sheet, rod, and tube arms when the test is made on the finished product.

Procedure: Parts are dried in an oven for a specified time and temperature and then placed in a desiccator to cool. Upon cooling, the specimens are weighed to establish a point of reference. The material is then submerged in water at standardized conditions (usually 23°C for 24 hours or until equilibrium). Specimens are removed from the liquid, dried and weighed.

What affects water absorption?

Type of plastic

Morphology (crystalline, amorphous…)

Type and proportion of additives, fillers and reinforcements used

Fiber fraction and orientation (in composites)

Relative humidity and temperature

Length of exposure

Water Absorption Values for Common Polymers

As the chart notes, some polymers such as Nylon (PA) have a higher rate of % gain from moisture absorption. However, polymers like PVDF and PTFE have a very low % gain in weight after the ASTM D570 test – which makes them excellent candidates for applications where moisture is a factor.

Performance thermoplastics are often exposed to high temperature applications (aircraft engines) which also absorb high levels of moisture. This is common in materials such as PBI (Celazole) and PAI (Torlon), since these polymers absorb moisture at high rates but are also specified in high temperature applications.

Basically, what can happen is that these materials absorb the moisture if not properly stored and packaged. Then if subject to high levels of heat without time for the moisture to dissipate, the internal moisture boils and turns to steam causing the parts to crack and blister.

Managing Moisture Absorption

For predictable machined part fit and performance, stock shapes and finished parts should be stored in a dry environment. Both finished parts and stock shapes should be packed in moisture barrier packaging. Only open packaging just prior to use. In the event that a part may have adsorbed so much moisture as to risk shocking it when placing it in high temperature or vacuum service, consider drying the material prior to use or re-use.

Your machining facility will have specifications on temperature and storage procedures for all polymers, stock shapes and components. When it comes to critical applications, work with a machine shop that has high standards for storing products. After all, machining a polymer is only part of the entire process; wasted machining, revenue and parts is not worth risking poor storage conditions. The table below shows some common packaging for polymers to increase and preserve shelf-life.

Generally, you can find a polymer’s 24 Hour and Saturation Moisture Absorption Values on a data chart. A chart can give a general idea of the moisture absorption, but an entire data set with the curve of a material is the best way to determine the right material for your project. Be sure to work with a plastics machining company that can provide you a wide range of data on the moisture absorption of polymers and composites. Your machinist will be able to identify how moisture and humidity will affect your project’s design and functionality. Talk to one our engineers at AIP about your project design, and we will work with you to provide unrivaled expertise from your project’s initial concept to completion.

Supporting Materials

Certifications and Regulatory Resources

Want to learn more about factors that contribute to effective CNC machining?

How Long It Takes Spray Paint to Dry & How to Speed up the Process

Some people think of spray paint as the weapon of choice for rebellious teenagers, but it can serve many purposes in your everyday life. It’s commonly used to restore the appearance of old machines, appliances, or furniture that have lost their shine.

The reason why it’s great is because it’s a cost-effective way to fix something rather than replacing it entirely. Instead of refurbishing your home, or purchasing new windows once yours have gone out of style — simply paint over them.

However, if you touch a fresh coat of spray paint, you could ruin everything and have to start over. So, the question is how long does it take spray paint to dry, and how to speed up the process?

How Long Does It Take Spray Paint to Dry?

The drying time depends on the material you’re applying it on, as well as on the number of coats, colors, etc. Also, if you want to add more than one coat, you have to let the first one dry before applying another one. You should also give the paint more time to dry if you’re using more than one color, to avoid making streaks.

Drying Stages

If you don’t want to ruin the job you have already done (and have to start over), you must wait for the paint to dry . There are 4 stages that paint goes through before the drying process is completed.

Surface Dry — You’ll see a thin layer on the surface of the paint and it will be quite sticky to the touch.

Touch Dry — During the touch dry stage, the paint can come off when you apply light pressure, even though it doesn’t stick to your fingers.

Hard Dry — The coat of paint can still be damaged during this phase, but it won’t completely come off.

Thorough Dry — You’ve given the paint about 24 hours to dry, and the painted object is ready to use.

Drying Time Based on Material

Different materials may be more porous or prone to damage from the paint, and you need to treat them accordingly. The time it takes to dry off a fresh coat of paint can also depend on what you’re painting on. The most common ones, that I’ll talk more about, are cardboard, metal, glass, plastic, and rubber.

Cardboard

Cardboard has a soft texture that makes it prone to accidental damage and you will likely ruin it if you don’t know what you’re doing. However, the material has one of the fastest drying times. If you’re painting cardboard in a well-ventilated area, it shouldn’t take more than 15 minutes for a coat to dry.

Metal

Spray paint is commonly used to restore a variety of metal objects, such as doorknobs, refrigerators, cars, etc. If you’re in a warm room with no humidity, spray paint can dry in as little as 10 minutes.

Glass

Painting on glass can be tricky, and not giving the paint enough time to dry can lead to drip marks. You should try to apply each coat as gently as possible, and wait for at least 15 minutes before adding a new one. However, it typically takes a minimum of 24 hours for the paint to dry fully.

Plastic

Plastic is one of the easiest materials to paint on and has an average drying time of 30 minutes. But, the paint coats likely won’t reach the thorough dry stage until you’ve let them sit for at least 3 hours.

Rubber

Because rubber is so porous, you should wait for at least 30 minutes before applying a new coat. Also, keep in mind that it won’t get to the thorough dry stage in less than 24 hours. If you want to paint an object made out of rubber, you have to plan ahead.

How to Speed up the Process

If you’re in a rush and need to use the chair you’ve just spray painted ASAP, there are a couple of things you can do to get it to dry. Next, I’ll cover a few tips and tricks to help things move along quicker.

Work Outside

Besides being able to breathe in the fresh air, working outside will help your paint dry quicker. However, you should plan ahead a bit and paint on a warm day, when the humidity is low. You should also try starting early in the morning to take advantage of the weather and give yourself enough time to finish.

Turn on a Fan

If you can’t avoid working indoors, at least turn on a fan to ensure better airflow in the room. This way, you will help the individual coats dry quicker, and won’t give yourself a headache from the fumes.

Run a Hairdryer

A hairdryer will help your paint dry quickly by decreasing humidity levels and increasing the temperature. However, if you’re working with a thinner material, don’t stand too close to it because you could cause damage. You could also use the cooling mode If your hairdryer has one, but don’t expect the results as quickly.

Apply Thin Coats

Although it seems a bit arduous, applying thin coats of spray paint can help you speed up the drying process. Thinner layers will also ensure you get a more even finish, without any streaks and patches.

Use Furniture Polish

Using furniture polish (especially a wax-based one) will let the paint dry quicker and not leave any drip marks. Spray the polish a few inches away from the object after applying spray paint, and give it a couple of minutes to dry before applying the next coat.

Other Factors That Contribute to Drying Time

How Thick the Layer of Paint Is

If the layer of coating is too thick it will take more time for it to dry. So, applying the correct amount of paint is crucial if you want it to dry quickly. Luckily, Spray paint gives you enough control when applying it, especially compared to a brush. Always add a thin layer of paint to ensure better results and quicker dry time. You can also mix a paint thinner or solvent to get a thinner level of paint before you start adding it.

Environmental factors

High levels of humidity can increase the drying time, no matter the material you’re painting on. On the other hand, cold temperatures can cause issues with the consistency of the paint. Always make sure you’re in a warm room with low humidity to ensure your paint takes less time to dry.

The Type of Spray Paint

The ingredients and formulas play a major role in shortening the time it takes coats of paint to dry. Currently, the best option on the market is polyurethane (epoxy) spray paint. The reason why is that it can dry a surface within 5 minutes, and give a hard dry in 1 hour. Lacquer paints are the second-best with a hard drying time of only 3 hours, and latex paints will take up to 8 hours to dry completely.

Final Thoughts

Spray paint is a portable, affordable, versatile, and quite effective at getting rid of any accidental scratches and signs of use. When it comes to how long it takes the spray paint to dry, there are certain factors you should consider. For example, temperature, weather conditions, and humidity levels are crucial when applying it. However, the kind of material and paint you’re using also needs to be taken into consideration.

You also need to track the drying stages to ensure you’re not just piling on new coats when the base layer hasn’t dried yet. Lastly, apply thin layers to ensure a quick dry time and an even result. Working with spray paint is incredibly simple, and I hope this article helps you get the results you want.

So you have finished reading the how to remove moisture from plastic topic article, if you find this article useful, please share it. Thank you very much. See more: plastic resin drying guide, how to dry wet pvc resin, plastic material drying temperature pdf, material drying equipment, plastic resin dryers, used conair plastic dryers, drying temperature for hdpe, conair plastic processing equipment