당신은 주제를 찾고 있습니까 “furnace radiant and convection section – Furnace Tube Inspection System – FTIS™“? 다음 카테고리의 웹사이트 https://chewathai27.com/you 에서 귀하의 모든 질문에 답변해 드립니다: https://chewathai27.com/you/blog. 바로 아래에서 답을 찾을 수 있습니다. 작성자 QuestIntegrityGrp 이(가) 작성한 기사에는 조회수 23,961회 및 좋아요 181개 개의 좋아요가 있습니다.

furnace radiant and convection section 주제에 대한 동영상 보기

여기에서 이 주제에 대한 비디오를 시청하십시오. 주의 깊게 살펴보고 읽고 있는 내용에 대한 피드백을 제공하세요!

d여기에서 Furnace Tube Inspection System – FTIS™ – furnace radiant and convection section 주제에 대한 세부정보를 참조하세요

Quest Integrity Group’s furnace tube inspection system, FTIS™, detects and measures damage mechanisms and deformations in the convection and radiant coils of process fired heaters.

furnace radiant and convection section 주제에 대한 자세한 내용은 여기를 참조하세요.

Industrial furnace – Wikipedia

Convection section. The convection section is located above the radiant section where it is cooler to recover additional heat.

Source: en.wikipedia.org

Date Published: 8/21/2022

View: 2597

API 560 Fired Heater Design – Convection Section – HeaterSIM

The main purpose of the convection section is to absorb energy from the hot flue gas leaving the radiant section. The convection Section usually consists of …

Source: www.heatersim.com

Date Published: 1/27/2021

View: 3817

Furnace – New World Encyclopedia

The convection section is located above the radiant section, where it is cooler to recover additional heat. In this section …

Source: www.newworldencyclopedia.org

Date Published: 10/18/2022

View: 218

Simulation of heat transfer in the convection section of fired …

Heat is transferred in a fired heater by both convection and radiation in both sections of the furnace, where radiation is the dominant type of heat transfer in …

Source: pp.bme.hu

Date Published: 11/26/2022

View: 9503

Fired Heaters – TechEngineering

The heater with radiant and convection section can reach higher power and allow higher efficiency. The convection section, which has horizontal axis, …

Source: www.techengineering.it

Date Published: 4/5/2021

View: 9632

Fired Heaters: Working, Components, Types, Function …

The portion of the heater in which the heat is transferred to tubes primarily by convection. Brge wall: The section separates the radiant & convection section …

Source: whatispiping.com

Date Published: 12/14/2021

View: 5658

FURNACES – Thermopedia

Furnaces employing combustion produce a hot gas which transfers heat to the material by radiation and convection. Sols are heated by direct contact, …

Source: www.thermopedia.com

Date Published: 8/18/2021

View: 3273

Unit 3. Furnaces

In a fired furnace, radiant heat is emitted from the combustion of … convection section because most of the heat it receives is by convection.

Source: portal.tpu.ru:7777

Date Published: 8/13/2021

View: 7007

주제와 관련된 이미지 furnace radiant and convection section

주제와 관련된 더 많은 사진을 참조하십시오 Furnace Tube Inspection System – FTIS™. 댓글에서 더 많은 관련 이미지를 보거나 필요한 경우 더 많은 관련 기사를 볼 수 있습니다.

주제에 대한 기사 평가 furnace radiant and convection section

- Author: QuestIntegrityGrp

- Views: 조회수 23,961회

- Likes: 좋아요 181개

- Date Published: 2015. 7. 22.

- Video Url link: https://www.youtube.com/watch?v=flUKuiD-Uso

What is convection section in furnace?

The convection section is located above the radiant section where it is cooler to recover additional heat. Heat transfer takes place by convection here, and the tubes are finned to increase heat transfer.

Which section of furnace tubes is heated by both radiation and convection?

The flames heat the tubes, which in turn heat the fluid inside in the first part of the furnace known as the radiant section or firebox. In this chamber, where combustion takes place, the heat is transferred mainly by radiation to tubes around the fire in the chamber.

Does a furnace use convection or radiation?

Furnaces employing combustion produce a hot gas which transfers heat to the material by radiation and convection. Solids are heated by direct contact, but fluids are usually heated indirectly, being carried inside pipes within the furnace.

What section of a furnace contains the burners?

The section in a furnace that contains the burners and open flames is called the firebox. The firebox is lined with a refractory layer, a brick lining that reflects heat back into the furnace.

What is the meaning of convection section?

[kən′vek·shən ‚sek·shən] (engineering) That portion of the furnace in which tubes receive heat from the flue gases by convection.

Where are the radiant tubes located in a furnace?

6. Where are the radiant tubes located in a furnace? Radiant tubes, or coils, are located along the walls of the firebox.

What is the principle of furnace?

Whatever fuel a furnace uses, it operates on the principle of forced air heating. The furnace transfers heat to air, which blower fans then send through the ductwork of a house and out vents.

What is furnace and its types?

There are four main types of furnaces: natural gas, oil, electric, and propane. Electric furnaces can heat the air by exposing heated elements, while other types of furnaces typically require a heat exchanger or chamber that warms the surrounding air.

What is heat duty of furnace?

9.1 Overview. Process heat duty is the heat required to be added or be removed from the process fluids to create the required change in temperature. It can be in the form of sensible heat, latent heat, or latent heat of vaporization.

What is radiant and convection?

Radiant heat warms objects and surfaces without heating the air in between. Those objects warm up directly and radiate back. Convection warms the air, which is a triple inefficiency. The air has to: Warm up.

How conduction is important in furnace?

In a fuel-fired heating process, heat enters the charge through its surface (by radiation or by convection) and diffuses throughout the charge by conduction. This heat flow requires a difference in temperature within the charge. Steady heat flows through a flat furnace charge.

How does a radiant heat system work?

Radiant floor heating systems produce heat through thermal radiation. By heating the floor rather than the surrounding air, they provide indirect, diffused heat that radiates from the floor up. This heat is absorbed by surrounding objects, and they in turn help to warm the entire room.

What are the different parts of a furnace?

- Pilot light. …

- Thermocouple. …

- Hot surface ignitor. …

- Flame sensor. …

- Gas valve. …

- Burners. …

- Heat exchanger. …

- Draft inducer motor.

What is the top part of a furnace called?

This photo shows you how the furnace is divided into two cabinets: the burner cabinet (top) and the blower cabinet (bottom).

What is heat exchanger in furnace?

The heat exchanger is the part of your furnace that heats your home’s air. It is made of metal coils that are designed to absorb and transfer heat. Here’s how the heating process works in your furnace: The burners in your furnace heat the coils of the heat exchanger.

Is convection forced air?

Natural and Forced: Two Forms of Convection

When the medium transferring the heat is moving by itself, that is called forced convection. An example would be when air is forced by a fan.

What is conduction in HVAC?

A heat exchanger in an HVAC system uses conduction to transfer heat. This is the traveling of heat energy from one molecule to another using direct contact with the temperature source. HVAC heat exchangers will either heat or cool the air with conduction, but they need the proper medium from which to get the energy.

Which heating equipment uses steam or hot water in providing heat to an interior space through intermediary fluid movement?

Household Furnaces. A household furnace is a major appliance that is permanently installed to provide heat to an interior space through intermediary fluid movement, which may be air, steam, or hot water.

Industrial furnace

Device used for providing heat in industrial applications

An industrial chamber furnace, used to heat steel billets for open-die forging

An industrial furnace, also known as a direct heater or a direct fired heater, is a device used to provide heat for an industrial process, typically higher than 400 degrees Celsius.[1] They are used to provide heat for a process or can serve as reactor which provides heats of reaction. Furnace designs vary as to its function, heating duty, type of fuel and method of introducing combustion air. Heat is generated by an industrial furnace by mixing fuel with air or oxygen, or from electrical energy. The residual heat will exit the furnace as flue gas.[1] These are designed as per international codes and standards the most common of which are ISO 13705 (Petroleum and natural gas industries — Fired heaters for general refinery service) / American Petroleum Institute (API) Standard 560 (Fired Heater for General Refinery Service). Types of industrial furnaces include batch ovens, vacuum furnaces, and solar furnaces. Industrial furnaces are used in applications such as chemical reactions, cremation, oil refining, and glasswork.

Overview [ edit ]

Schematic diagram of an industrial process furnace

Fuel flows into the burner and is burnt with air provided from an air blower. There can be more than one burner in a particular furnace which can be arranged in cells which heat a particular set of tubes. Burners can also be floor mounted, wall mounted or roof mounted depending on design. The flames heat up the tubes, which in turn heat the fluid inside in the first part of the furnace known as the radiant section or firebox. In this chamber where combustion takes place, the heat is transferred mainly by radiation to tubes around the fire in the chamber.

The fluid to be heated passes through the tubes and is thus heated to the desired temperature. The gases from the combustion are known as flue gas. After the flue gas leaves the firebox, most furnace designs include a convection section where more heat is recovered before venting to the atmosphere through the flue gas stack. (HTF=Heat Transfer Fluid. Industries also use their furnaces to heat a secondary fluid with special additives like anti-rust and high heat transfer efficiency. This heated fluid is then circulated round the whole plant to heat exchangers to be used wherever heat is needed instead of directly heating the product line as the product or material may be volatile or prone to cracking at the furnace temperature.)

Components [ edit ]

Radiant section [ edit ]

Middle of radiant section

The radiant section is where the tubes receive almost all its heat by radiation from the flame. In a vertical, cylindrical furnace, the tubes are vertical. Tubes can be vertical or horizontal, placed along the refractory wall, in the middle, etc., or arranged in cells. Studs are used to hold the insulation together and on the wall of the furnace. They are placed about 1 ft (300 mm) apart in this picture of the inside of a furnace.

The tubes, shown below, which are reddish brown from corrosion, are carbon steel tubes and run the height of the radiant section. The tubes are a distance away from the insulation so radiation can be reflected to the back of the tubes to maintain a uniform tube wall temperature. Tube guides at the top, middle and bottom hold the tubes in place.

Convection section [ edit ]

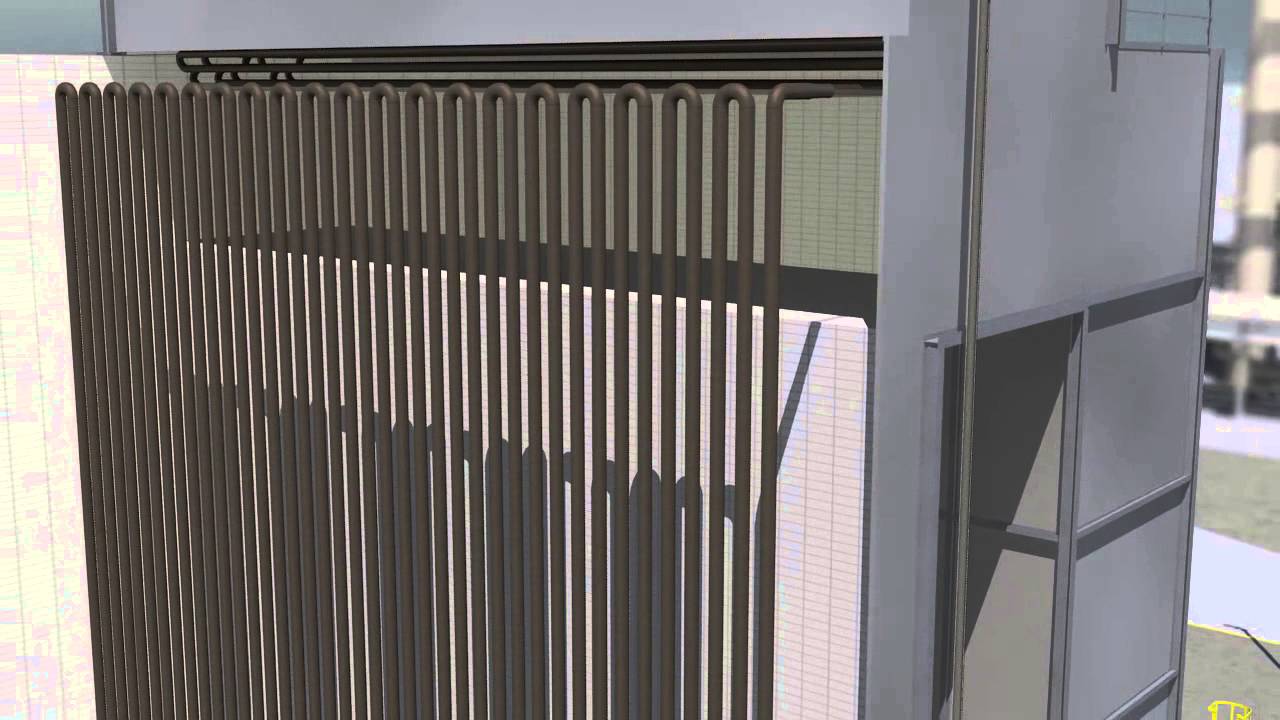

Convection section

The convection section is located above the radiant section where it is cooler to recover additional heat. Heat transfer takes place by convection here, and the tubes are finned to increase heat transfer. The first three tube rows in the bottom of the convection section and at the top of the radiant section is an area of bare tubes (without fins) and are known as the shield section (“shock tubes”), so named because they are still exposed to plenty of radiation from the firebox and they also act to shield the convection section tubes, which are normally of less resistant material from the high temperatures in the firebox.

The area of the radiant section just before flue gas enters the shield section and into the convection section called the bridgezone. A crossover is the tube that connects from the convection section outlet to the radiant section inlet. The crossover piping is normally located outside so that the temperature can be monitored and the efficiency of the convection section can be calculated. The sightglass at the top allows personnel to see the flame shape and pattern from above and visually inspect if flame impingement is occurring. Flame impingement happens when the flame touches the tubes and causes small isolated spots of very high temperature.

Radiant coil [ edit ]

This is a series of tubes horizontal/ vertical hairpin type connected at ends (with 180° bends) or helical in construction. The radiant coil absorbs heat through radiation. They can be single pass or multi pass depending upon the process-side pressure drop allowed. The radiant coils and bends are housed in the radiant box. Radiant coil materials vary from carbon steel for low temperature services to high alloy steels for high temperature services. These are supported from the radiant side walls or hanging from the radiant roof. Material of these supports is generally high alloy steel. While designing the radiant coil, care is taken so that provision for expansion (in hot conditions) is kept.

Burner [ edit ]

Furnace burner

The burner in the vertical, cylindrical furnace as above, is located in the floor and fires upward. Some furnaces have side fired burners, such as in train locomotives. The burner tile is made of high temperature refractory and is where the flame is contained. Air registers located below the burner and at the outlet of the air blower are devices with movable flaps or vanes that control the shape and pattern of the flame, whether it spreads out or even swirls around. Flames should not spread out too much, as this will cause flame impingement. Air registers can be classified as primary, secondary and if applicable, tertiary, depending on when their air is introduced.

The primary air register supplies primary air, which is the first to be introduced in the burner. Secondary air is added to supplement primary air. Burners may include a pre-mixer to mix the air and fuel for better combustion before introducing into the burner. Some burners even use steam as premix to preheat the air and create better mixing of the fuel and heated air. The floor of the furnace is mostly made of a different material from that of the wall, typically hard castable refractory to allow technicians to walk on its floor during maintenance.

A furnace can be lit by a small pilot flame or in some older models, by hand. Most pilot flames nowadays are lit by an ignition transformer (much like a car’s spark plugs). The pilot flame in turn lights up the main flame. The pilot flame uses natural gas while the main flame can use both diesel and natural gas. When using liquid fuels, an atomizer is used, otherwise, the liquid fuel will simply pour onto the furnace floor and become a hazard. Using a pilot flame for lighting the furnace increases safety and ease compared to using a manual ignition method (like a match).

Sootblower [ edit ]

Sootblowers are found in the convection section. As this section is above the radiant section and air movement is slower because of the fins, soot tends to accumulate here. Sootblowing is normally done when the efficiency of the convection section is decreased. This can be calculated by looking at the temperature change from the crossover piping and at the convection section exit.

Sootblowers utilize flowing media such as water, air or steam to remove deposits from the tubes. This is typically done during maintenance with the air blower turned on. There are several different types of sootblowers used. Wall blowers of the rotary type are mounted on furnace walls protruding between the convection tubes. The lances are connected to a steam source with holes drilled into it at intervals along its length. When it is turned on, it rotates and blows the soot off the tubes and out through the stack.

Stack [ edit ]

Stack damper

The flue gas stack is a cylindrical structure at the top of all the heat transfer chambers. The breeching directly below it collects the flue gas and brings it up high into the atmosphere where it will not endanger personnel.

The stack damper contained within works like a butterfly valve and regulates draft (pressure difference between air intake and air exit) in the furnace, which is what pulls the flue gas through the convection section. The stack damper also regulates the heat lost through the stack. As the damper closes, the amount of heat escaping the furnace through the stack decreases, but the pressure or draft in the furnace increases which poses risks to those working around it if there are air leakages in the furnace, the flames can then escape out of the firebox or even explode if the pressure is too great.

Insulation [ edit ]

Insulation is an important part of the furnace because it improves efficiency by minimizing heat escape from the heated chamber. Refractory materials such as firebrick, castable refractories and ceramic fibre, are used for insulation. The floor of the furnace are normally castable type refractories while those on the walls are nailed or glued in place. Ceramic fibre is commonly used for the roof and wall of the furnace and is graded by its density and then its maximum temperature rating. For example, 8# 2,300 °F means 8 lb/ft3 density with a maximum temperature rating of 2,300 °F. The actual service temperature rating for ceramic fiber is a bit lower than the maximum rated temperature. (i.e. 2300 °F is only good to 2145 °F before permanent linear shrinkage).

Foundations [ edit ]

Concrete pillars are foundation on which the heater is mounted. They can be four nos. for smaller heaters and may be up to 24 nos. for large size heaters. Design of pillars and entire foundation is done based on the load bearing capacity of soil and seismic conditions prevailing in the area. Foundation bolts are grouted in foundation after installation of the heater.

Access doors [ edit ]

The heater body is provided with access doors at various locations. Access doors are to be used only during shutdown of heater. The normal size of the access door is 600×400 mm, which is sufficient for movement of people/ material into and out of the heater. During operation the access doors are properly bolted using leak proof high temperature gaskets.

See also [ edit ]

References [ edit ]

New World Encyclopedia

Tiangong Kaiwu Illustrations of Chinese silversmiths smelting silver ore and separating lead from it. Taken from encyclopedia (1637), by Song Yingxing (1587-1666).

A furnace (from the Latin word fornax, meaning “oven”) is an appliance that produces heat. The heat in a furnace is usually produced by combustion of a fuel such as oil, wood, or natural gas. The heat may also be generated by electricity, as in an electric arc furnace, or by induction heating in an induction furnace.

In American English, the term furnace generally refers to the central heater in a home or office, or the heater for an industrial process, and sometimes it is a synonym for kiln, a device used in the production of ceramics. In British English, the term furnace almost exclusively means an industrial furnace, whereas a household heater is called a boiler or heater. Industrial furnaces are used for many applications, such as the extraction of metals from ores (smelting), the running of chemical reactions, or the refining of oil by fractional distillation.

Household Furnaces

A household furnace is a major appliance that is permanently installed to provide heat to an interior space through intermediary fluid movement, which may be air, steam, or hot water. The most common fuel source for modern furnaces in the United States is natural gas; other common fuel sources include LPG (liquefied petroleum gas), fuel oil, coal or wood. In some cases electrical resistance heating is used as the source of heat, especially where the cost of electricity is low.

Combustion furnaces always need to be vented to the outside. Traditionally, this was through a chimney, which tends to expel heat along with the exhaust. Modern high-efficiency furnaces can be 98 percent efficient and operate without a chimney.[1] The small amount of waste gas and heat are mechanically ventilated through a small tube through the side or roof of the house.

Modern household furnaces are classified as condensing or non-condensing, based on their efficiency in extracting heat from exhaust gases. Furnaces with efficiencies greater than approximately 89 percent extract so much heat from the exhaust that water vapor in the exhaust condenses; they are referred to as condensing furnaces. Such furnaces must be designed to avoid the corrosion that this highly acidic condensate might cause and may need to include a condensate pump to remove the accumulated water. Condensing furnaces can typically deliver savings of 20-35 percent in heating costs, if the old furnace was in the 60 percent Annual Fuel Utilization Efficiency (AFUE) range.

Heat Distribution

The furnace transfers heat to the living space of the building through an intermediary distribution system. If the distribution is through hot water (or other fluid) or through steam, then the furnace is more commonly termed a boiler. One advantage of a boiler is that the furnace can provide hot water for bathing and washing dishes, rather than requiring a separate water heater. A disadvantage, however, is that when the boiler breaks down, it results in loss of both heat and hot water.

A condensing furnace

Air convection heating systems have been in use for over a century, but the older systems relied on a passive air circulation system, in which the higher density of cooler air caused it to sink into the furnace, and the lower density of warmer air caused it to rise in the ductwork. The two forces acted together to drive air circulation in a system, known as “gravity-feed.” The layout of the ducts and furnace was optimized for short, large ducts and the furnace was therefore referred to as an “octopus” furnace.

By comparison, most modern “warm air” furnaces typically use a fan to circulate air into the rooms of house and pull cooler air back to the furnace for reheating. This is called forced-air heat. Because the fan easily overcomes the resistance of the ductwork, the arrangement of ducts can be far more flexible than the octopus of old. In American practice, separate ducts collect cool air to be returned to the furnace. At the furnace, cool air passes into the furnace, usually through an air filter, through the blower, then through the heat exchanger of the furnace, from where it is blown throughout the building. One major advantage of this type of system is that it also enables easy installation of central air conditioning by simply adding a cooling coil at the exhaust of the furnace.

Air is circulated through ductwork, which may be made of sheet metal or plastic “flex” duct and insulated or uninsulated. Unless the ducts and plenums have been sealed using mastic or foil duct tape, the ductwork is likely to have a high leakage of conditioned air, possibly into unconditioned spaces. Another cause of wasted energy is the installation of ductwork in unheated areas, such as attics and crawl spaces; or ductwork of air conditioning systems in attics in warm climates.

The following rare but difficult-to-diagnose failure can occur. If the temperature inside the furnace exceeds a maximum threshold, a safety mechanism with a thermostat will shut the furnace down. A symptom of this failure is that the furnace repeatedly shuts down before the house reaches the desired temperature; this is commonly referred to as the furnace “riding the high limit switch.” This condition commonly occurs if the temperature setting of the high limit thermostat is set too close to the normal operating temperature of the furnace. Another situation may occur if a humidifier is incorrectly installed on the furnace and the duct that directs a portion of the humidified air back into the furnace is too large. The solution is to reduce the diameter of the cross-feed tube, or to install a baffle that reduces the volume of re-fed air.

Industrial process furnaces

An industrial furnace, or direct-fired heater, is an equipment that provides heat for a process or chemical reaction. Furnace designs vary as to their function, heating duty, type of fuel, and method of introducing combustion air. However, most process furnaces have some common features.

Fuel flows into the burner and is burnt with air provided from an air blower. A given furnace may have more than one burner, arranged in cells that heat a set of tubes. Burners can be floor-mounted, wall-mounted, or roof-mounted, depending on design. The flames heat the tubes, which in turn heat the fluid inside in the first part of the furnace known as the radiant section or firebox. In this chamber, where combustion takes place, the heat is transferred mainly by radiation to tubes around the fire in the chamber. The heating fluid passes through the tubes and is thus heated to the desired temperature.

The gases from the combustion are known as flue gas. After the flue gas leaves the firebox, most furnace designs include a convection section where more heat is recovered before venting to the atmosphere through the flue gas stack.

In industrial furnaces, a common approach is to heat a secondary fluid called a heat transfer fluid (HTF) that has high heat-transfer efficiency and may contain special additives (such as an anti-rust agent). This heated fluid is then circulated around the whole plant to heat exchangers to be used wherever heat is needed, instead of directly heating the product line, as the product or material may be volatile or prone to cracking at the furnace temperature.

Radiant section

The radiant section is where the tubes receive almost all their heat by radiation from the flame. In a vertical, cylindrical furnace, the tubes are vertical. Tubes can be vertical or horizontal, placed along the refractory wall or around the middle, or arranged in cells. Studs are used to hold the insulation together and on the wall of the furnace. They are placed about one foot (300 mm) apart in the following picture of the inside of a furnace. The tubes, which are reddish brown from corrosion, are carbon steel tubes and run the height of the radiant section. The tubes are a distance away from the insulation so that radiation can be reflected to the back of the tubes to maintain a uniform tube wall temperature. Tube guides at the top, middle, and bottom hold the tubes in place.

Convection section

The convection section is located above the radiant section, where it is cooler to recover additional heat. In this section, heat transfer takes place by convection, and the tubes are finned to increase heat transfer. The first two tube rows at the bottom of the convection section and the top of the radiant section form an area of bare tubes (without fins) and are known as the “shield section,” because they are exposed to plenty of radiation from the firebox and they also shield the convection section tubes, which are normally of less resistant material from the high temperatures in the firebox.

The area of the radiant section just before the flue gas enters the shield section and then the convection section is called the “bridge zone.” The term “crossover” is used to describe the tube that connects from the convection section outlet to the radiant section inlet. The crossover piping is normally located outside, so that the temperature can be monitored and the efficiency of the convection section can be calculated. The sightglass at the top allows personnel to observe the flame shape and pattern from above and to check for “flame impingement”—that is, whether the flame is touching the tubes, causing small, isolated spots of very high temperature.

Burner

The burner in a vertical, cylindrical furnace is generally located in the floor and fires upward. Some furnaces have side-fired burners, as in train locomotives. The burner tile is made of high-temperature refractory material that contains the flame. Air registers located below the burner and at the outlet of the air blower are devices with movable flaps or vanes that control the shape and pattern of the flame, whether it spreads out or swirls around. Flames should not spread out too much, as this will cause flame impingement.

Air registers can be classified as primary, secondary, and (if applicable) tertiary, depending on when the air is introduced. The primary air register supplies primary air, which is the first batch of air to be introduced in the burner. Secondary air is added to supplement primary air. Burners may include a premixer to mix the air and fuel for better combustion before introducing it into the burner. Some burners even use steam in the premix, to preheat the air and create better mixing of the fuel and heated air. The furnace floor is mostly made of a different material from that of the wall, typically hard castable refractory that allows technicians to walk on its floor during maintenance.

A furnace can be lit by a small pilot flame or (in some older models) matches. Most pilot flames nowadays are lit by an ignition transformer (much like a car’s spark plugs). The pilot flame in turn lights up the main flame. The pilot flame uses natural gas, while the main flame may use both diesel and natural gas. For liquid fuels, the fuel is passed through an atomizer, to prevent the liquid fuel from pouring onto the furnace floor and becoming a hazard. Using a pilot flame for lighting the furnace increases safety and ease (compared to using a match).

Sootblower

Sootblowers are found in the convection section. As this section is above the radiant section and air movement is slowed by the fins, soot tends to accumulate here. Sootblowing is normally done when the efficiency of the convection section is decreased. This can be calculated by looking at the temperature change from the crossover piping and at the convection section exit.

Sootblowers utilize flowing media such as water, air, or steam to remove deposits from the tubes. This is typically done during maintenance, with the air blower turned on. Several different types of sootblowers are available. Wall blowers of the rotary type are mounted on furnace walls protruding between the convection tubes. The lances are connected to a steam source with holes drilled into it at intervals along its length. When it is turned on, it rotates and blows the soot off the tubes and out through the stack.

Stack

The flue gas stack is a cylindrical structure at the top of the heat transfer chamber. The breeching directly below it collects the flue gas and releases it high in the atmosphere where it will not endanger personnel.

The stack contains a damper that works like a butterfly valve and regulates the draft (pressure difference between air intake and air outflow) in the furnace. The draft pulls the flue gas through the convection section. The stack damper also regulates the heat lost through the stack. As the damper closes, the amount of heat escaping the furnace through the stack decreases, but the pressure or draft in the furnace increases. This pressure increase poses risks to those working around the furnace if there are air leakages in the furnace, because the flames may then escape out of the firebox or even explode if the pressure is too high.

Insulation

Insulation is an important part of the furnace because it prevents excessive heat loss. Refractory materials such as firebrick, castable refractories, and ceramic fiber are used for insulation. The floors of the furnace are normally castable type refractories, while the refractories on the walls are nailed or glued in place. Ceramic fiber is commonly used for the roof and wall of the furnace and is graded by its density and then its maximum temperature rating. For example, a grade of “8# 2,300°F” means the material has a density of eight lb/ft3 and a maximum temperature rating of 2,300°F. An example of a material with castable composition is kastolite.

Metallurgical furnaces

In metallurgy, several specialized furnaces are used, a number of which are listed below.

Furnaces used in smelters: The blast furnace, used to reduce iron ore to pig iron Steelmaking furnaces, including: Puddling furnace Reverberatory furnace Bessemer converter Open hearth furnace Basic oxygen furnace Electric arc furnace Electric induction furnace

Furnaces used to remelt metal in foundries.

Furnaces used to reheat and heat treat metal for use in: Rolling mills, including tinplate works and slitting mills. Forges.

Vacuum furnaces to heat metals and other materials to very high temperatures, in the presence of a vacuum that reduces potential sources of contamination.

Outdoor wood-fired boilers

Description

An outdoor wood-fired boiler (OWB), also known as a waterstove, wood boiler, or outdoor wood furnace, is a heating technology that has grown in popularity in the northern United States. In most cases, an OWB looks like a small shack with metal siding. It is self-contained, connected to the building it heats through underground insulated water pipes. It contains a metal combustion chamber for a wood fire, surrounded by a water tank or water jacket. The fire heats the water, which is then circulated through the insulated water pipes into the building that is being heated. Once the hot water from the boiler reaches the building, the heat can be transferred to most existing heating systems and the building’s hot water supply.

A damper and fan on the boiler interacts with a thermostat in the building. If the building’s temperature falls, the thermostat triggers the damper to open, allowing more oxygen to enter the combustion chamber. As a result, the fire burns more intensely and raises the water temperature, thereby increasing the heat supplied to the building.

Benefits

OWBs offer several benefits that have increased their popularity. Their large combustion chamber accommodates more fuel than many other forms of wood heat, decreasing the number of times an owner has to add fuel to the fire. Home insurance may cost more for people who heat with an indoor form of wood heat than with an OWB.[2] Moreover, for people with a large supply of free wood and willing to invest the time to prepare the wood and stock the OWB, an OWB can be less expensive than heating with gas, oil, or electricity.

Controversy

OWBs are not without controversy, as their emissions sometimes bother neighbors. Some states and municipalities have banned the devices.[3] They are not currently regulated by the United States Environmental Protection Agency (EPA), unlike other forms of wood heat.[4] Recently, however, the EPA has worked with manufacturers to develop a method for them to identify OWBs that meet a voluntary emissions standard.[5] Some studies conducted on OWBs suggest that they may produce more emissions, most notably particulate matter under 2.5 micrometers (PM 2.5), compared with other heating technologies, but manufacturers dispute these assessments.[6] Exposure to elevated levels of PM 2.5 has been associated with cardiopulmonary health effects and premature death.[7]

As of July 2006, the Hearth, Patio and Barbecue Association (HPBA) and many of the major OWB manufacturers have requested users of their products to follow the “Outdoor Wood Furnace Best Burn Practices.”[8] These guidelines have been set up by the HPBA to help cut down on problems associated with OWBs.

Early in January 2007, the United States Environmental Protection Agency (EPA) initiated a voluntary program for manufacturers of outdoor wood furnaces.[5] The EPA’s primary intent is to encourage manufacturers to produce cleaner models known as Outdoor Wood-fired Hydronic Heaters (OWHH). The EPA also wants those who buy an OWHH/OWB to buy the cleanest models available, which are those that meet EPA performance verified levels. To participate in this program, manufacturers are developing cleaner models, with the goal of distributing these units starting in April 2007.[9]

The EPA now publishes a list of all OWHH/OWB units that pass the new voluntary program.[10] These furnaces come with the ‘orange EPA OWHH tag’ to notify the customer of the unit’s particular emission level output.

See also

Boiler

Cremation

Geothermal system

Humidifier

HVAC

Oven

Solar power

Thermodynamics

Notes

References ISBN links support NWE through referral fees

Davies, Clive. 1970. Calculations in Furnace Technology , 1st ed. Oxford, UK: Pergamon Press. ISBN 0080133665

, 1st ed. Oxford, UK: Pergamon Press. ISBN 0080133665 Dukelow, Samuel G. 1985. Improving Boiler Efficiency , 2nd ed. Research Triangle Park, NC: Instrument Society of America. ISBN 0876648529

, 2nd ed. Research Triangle Park, NC: Instrument Society of America. ISBN 0876648529 Fiveland, W.A., A.L. Crosbie, A.M. Smith, and T.F. Smith (eds.). 1991. Fundamentals of Radiation Heat Transfer . New York: American Society of Mechanical Engineers. ISBN 0791807290

. New York: American Society of Mechanical Engineers. ISBN 0791807290 Goldstick, R., and A. Thumann. 1986. Principles of Waste Heat Recovery . Atlanta, GA: Fairmont Press. ISBN 0881730157

. Atlanta, GA: Fairmont Press. ISBN 0881730157 Gray, W.A., and R. Muller. 1974. Engineering Calculations in Radiative Heat Transfer , 1st ed. Oxford, UK: Pergamon Press Ltd. ISBN 0080177875

, 1st ed. Oxford, UK: Pergamon Press Ltd. ISBN 0080177875 Lieberman, P., and E.T. Lieberman. 2003. Working Guide to Process Equipment , 2nd ed. New York: McGraw-Hill. ISBN 0071390871

, 2nd ed. New York: McGraw-Hill. ISBN 0071390871 Perry, R.H., and D.W. Green (eds.). 1997. Perry’s Chemical Engineers’ Handbook , 7th ed. New York: McGraw-Hill. ISBN 0070498415

, 7th ed. New York: McGraw-Hill. ISBN 0070498415 Warring, R.H. 1982. Handbook of Valves, Piping and Pipelines . Houston, TX: Gulf Publishing Company. ISBN 0872018857

. Houston, TX: Gulf Publishing Company. ISBN 0872018857 Whitehouse, R.C. (ed.). 1993. The Valve and Actuator User’s Manual. London, UK: Mechanical Engineering Publications. ISBN 0852988052

FURNACES

Introduction A furnace is a device in which heat is generated and transferred to materials with the object of bringing about physical and chemical changes. The source of heat is usually combustion of solid, liquid or gaseous fuel, or electrical energy applied through resistance heating (Joule heating) or inductive heating. However, solar energy can provide a clean source of high temperature if focused onto a small area. This was recognized over two hundred years ago by Lavoisier who built a large mobile “magnifying glass” system, Figure 1, to bring about the combustion of metals in a sealed glass container and subsequently the demise of the phlogiston theory. Figure 1. Lavoisier’s solar powered furnace c 1774. Furnaces employing combustion produce a hot gas which transfers heat to the material by radiation and convection. Solids are heated by direct contact, but fluids are usually heated indirectly, being carried inside pipes within the furnace. Alternatively, a Regenerative Heat Exchanger may be used to transfer heat from the combustion gases. Indirect heating has the advantage of avoiding contamination by combustion products. There are two principle categories of indirect heating furnace. The first is that of Boilers, where the heat is used to generate steam for power generation or process plant use. The second is that of furnaces designed to heat process fluids other than water. Some of the latter category are conventional heaters used simply to increase the fluid temperature, others are process heaters used to bring about physical and chemical changes in the products, for example distillation, and pyrolysis of hydrocarbons or catalytic steam-gas reforming of synthetic natural gas.

Process Heaters In the petrochemical industry process furnaces, or process heaters, are usually fired by oil or gas. They are designed to ensure that the fluid receives the right amount of heat and has the required residence time within specified temperature limits. This is achieved by appropriate disposition of tubes and careful control of firing rate and fluid flow. The following Figure 2 shows three typical geometries. Figure 2. Process heaters. (From the Heat Exchanger Design Handbook, Hemisphere Publications. With permission.)

Furnace Fuels The following tables give the properties of gaseous, liquid and solid fuels used in furnaces. Gross calorific value includes the heat released by the condensation and cooling of combustion products, and the combustion air/fuel ratio is the stoichiometric value based on theoretically perfect combustion (see Combustion). In practice, excess air is required to ensure complete combustion. The excess is usually about 10% of the stoichiometric value for premixed gaseous fuels, 20% for distillate oil and pulverized coal, and 30% for residual oil, although lower values may be achieved with efficient burners. Table 1. Properties of selected gaseous fuelsa (aFrom the Heat Exchanger Design Handbook , Hemisphere Publications. With permission.)

Furnace Heat Balance The rate of heat released in a fuel fired furnace is given by the product of the mass rate of feed of fuel, , and the calorific value Δh f , i.e., (1) The heat generated by combustion appears initially as sensible heat in the gaseous products of combustion, generated at the rate . If this were an adiabatic process (i.e., no heat transfer), the gas would attain the adiabatic flame temperature, T f , given by (2) where T 0 is the inlet air/fuel temperature and c pg an appropriate averaged specific heat capacity of the gases for the range T 0 to T f . However, as illustrated in Figure 3, part of the heat generated passes to the tubes containing the process fluid at rate and part is lost through the furnace walls at rate . The remainder escapes at rate as waste heat of the combustion products leaving the furnace. The overall heat balance therefore is (3) Because of this the actual gas temperature, T g , reached in the furnace is less than the adiabatic flame temperature, T f . Neglecting wall losses an approximate value of T g can be obtained from (4) For example, in a typical oil fired furnace the value of T f is 2,200 K and the value of T g is 1,300 K [Shires, Hewitt and Bott (1994)]. Table 2. Properties of selected liquid and solid fuelsa (aFrom the Heat Exchanger Design Handbook , Hemisphere Publications. With permission.) Figure 3. Furnace heat balances. The rate of heat transfer, , from the hot gases to the tubes is a function of the gas temperature as well as the radiation properties of the gases, the geometry of the furnace and tubes, and the emissivity of the tube surface. In applying simple furnace models iteration is therefore necessary.

Furnace Radiation In most process heaters, the major part of the heat transfer from the hot gases to the tubes is by radiation. To calculate the radiative component it is necessary to know the effective emissivity, ε g , of the combustion gases (typical value 0.25). This is dependent on the ratio of the partial pressures of CO 2 and H 2 , the temperatures of the gas and the radiation source and the effective size of the radiating gas cloud. The latter is represented by the term pLo, the product of partial pressure and effective length of the furnace—a term first introduced by H. C. Hottel. For details of the procedure see Hottel and Sarofim (1967) and Hewitt, Shires and Bott (1994). The rate of heat transfer to the furnace product is also a function of the geometry of the tube banks and the fraction of the furnace surface area covered by them. If the effective area of the tubes, A 1 , is only a small fraction of the total area. A t , (Figure 4a), the surface receives blackbody radiation (see Radiative Heat Transfer) and the rate of heat transfer is independent of gas emissivity, ε g , i.e., (5) where ε 1 is the effective emissivity of the receiving surface and T 1 its temperature and σ is the Stefan-Boltzmann constant, 5.670 × 10−8 W/m2K4. On the other hand, if A 1 is almost equal to the total surface area, A t , then (6) Intermediate ratios are covered by the speckled surface equation [Hottel and Sarofim (1967)]. (7) where C = A 1 /A t . Figure 4. Effect of heat sink area on effective emissivity. (a) Small heat sink area; (b) large heat sink area; (e) example based on Eq. (7) with ε g = 0.3 and ε 1 = 0.85.

Effects of Tube Bank Geometry In practice the area, A 1 , receiving radiation is a tube bank, Figure 5, which intercepts only a fraction of the incident radiation; some passes through to the refractory wall and is re-irradiated. For a detailed analysis see Hottel and Sarofim (1967). Figure 5. Plane surface equivalent of tube bank heat sink; B = p/d. The fraction of radiation intercepted by a single row of tubes having a pitch to diameter ratio B (equals p/d) is given by (8) Figure 6 shows F as a function of B for one and two rows of tubes. Figure 6. Fraction of incident radiation intercepted by tubes. (From the Heat Exchanger Design Handbook, Hemisphere Publications. With permission.) The effective emissivity based on the projected area using Eq. (7) and allowing for re-irradiation from the refractory backing is (9) This is illustrated in Figure 7 for a typical tube surface emissivity of 0.85. Figure 7. Effective emissivity of equivalent plane surface. The relationship between the rate of heat transfer, , from the gas to the tubes and the gas temperature, T g , is obtained by combining Eqs. (6), (7) and (8). This in turn can be combined with Eq. (3) to determine the furnace thermal characteristics. An example of this procedure is described in Hewitt, Shires and Bolt (1994).

Furnace Models The complete mathematical description of a practical furnace is complex, combining aerodynamics, chemical reactions and heat transfer, and computer programs are normally used for detailed solutions. There are two basic types of approach; zone methods and flux methods. Zone methods are employed when the heat release pattern from the flame is known or can be calculated independently. Conceptually, the furnace and its walls are divided into discrete zones, the effective exchange areas between zones are determined, and radiative heat transfer corresponding to the prescribed heat release pattern is calculated. In flux methods, instead of dividing the space into zones the radiation arriving at a point in the system is itself divided into a number of characteristic directions, representing averages over a specified solid angle. Flux methods are well suited for use in combination with modern methods of prediction of fluid flow and mixing. Simultaneous solutions of the radiative heat transfer equations using flux methods and turbulent flow models are feasible. For further information on these two methods see Beer (1974), and Afgan and Beer (1974), where examples of their application can be found.

Industrial furnace

Device used for providing heat in industrial applications

An industrial chamber furnace, used to heat steel billets for open-die forging

An industrial furnace, also known as a direct heater or a direct fired heater, is a device used to provide heat for an industrial process, typically higher than 400 degrees Celsius.[1] They are used to provide heat for a process or can serve as reactor which provides heats of reaction. Furnace designs vary as to its function, heating duty, type of fuel and method of introducing combustion air. Heat is generated by an industrial furnace by mixing fuel with air or oxygen, or from electrical energy. The residual heat will exit the furnace as flue gas.[1] These are designed as per international codes and standards the most common of which are ISO 13705 (Petroleum and natural gas industries — Fired heaters for general refinery service) / American Petroleum Institute (API) Standard 560 (Fired Heater for General Refinery Service). Types of industrial furnaces include batch ovens, vacuum furnaces, and solar furnaces. Industrial furnaces are used in applications such as chemical reactions, cremation, oil refining, and glasswork.

Overview [ edit ]

Schematic diagram of an industrial process furnace

Fuel flows into the burner and is burnt with air provided from an air blower. There can be more than one burner in a particular furnace which can be arranged in cells which heat a particular set of tubes. Burners can also be floor mounted, wall mounted or roof mounted depending on design. The flames heat up the tubes, which in turn heat the fluid inside in the first part of the furnace known as the radiant section or firebox. In this chamber where combustion takes place, the heat is transferred mainly by radiation to tubes around the fire in the chamber.

The fluid to be heated passes through the tubes and is thus heated to the desired temperature. The gases from the combustion are known as flue gas. After the flue gas leaves the firebox, most furnace designs include a convection section where more heat is recovered before venting to the atmosphere through the flue gas stack. (HTF=Heat Transfer Fluid. Industries also use their furnaces to heat a secondary fluid with special additives like anti-rust and high heat transfer efficiency. This heated fluid is then circulated round the whole plant to heat exchangers to be used wherever heat is needed instead of directly heating the product line as the product or material may be volatile or prone to cracking at the furnace temperature.)

Components [ edit ]

Radiant section [ edit ]

Middle of radiant section

The radiant section is where the tubes receive almost all its heat by radiation from the flame. In a vertical, cylindrical furnace, the tubes are vertical. Tubes can be vertical or horizontal, placed along the refractory wall, in the middle, etc., or arranged in cells. Studs are used to hold the insulation together and on the wall of the furnace. They are placed about 1 ft (300 mm) apart in this picture of the inside of a furnace.

The tubes, shown below, which are reddish brown from corrosion, are carbon steel tubes and run the height of the radiant section. The tubes are a distance away from the insulation so radiation can be reflected to the back of the tubes to maintain a uniform tube wall temperature. Tube guides at the top, middle and bottom hold the tubes in place.

Convection section [ edit ]

Convection section

The convection section is located above the radiant section where it is cooler to recover additional heat. Heat transfer takes place by convection here, and the tubes are finned to increase heat transfer. The first three tube rows in the bottom of the convection section and at the top of the radiant section is an area of bare tubes (without fins) and are known as the shield section (“shock tubes”), so named because they are still exposed to plenty of radiation from the firebox and they also act to shield the convection section tubes, which are normally of less resistant material from the high temperatures in the firebox.

The area of the radiant section just before flue gas enters the shield section and into the convection section called the bridgezone. A crossover is the tube that connects from the convection section outlet to the radiant section inlet. The crossover piping is normally located outside so that the temperature can be monitored and the efficiency of the convection section can be calculated. The sightglass at the top allows personnel to see the flame shape and pattern from above and visually inspect if flame impingement is occurring. Flame impingement happens when the flame touches the tubes and causes small isolated spots of very high temperature.

Radiant coil [ edit ]

This is a series of tubes horizontal/ vertical hairpin type connected at ends (with 180° bends) or helical in construction. The radiant coil absorbs heat through radiation. They can be single pass or multi pass depending upon the process-side pressure drop allowed. The radiant coils and bends are housed in the radiant box. Radiant coil materials vary from carbon steel for low temperature services to high alloy steels for high temperature services. These are supported from the radiant side walls or hanging from the radiant roof. Material of these supports is generally high alloy steel. While designing the radiant coil, care is taken so that provision for expansion (in hot conditions) is kept.

Burner [ edit ]

Furnace burner

The burner in the vertical, cylindrical furnace as above, is located in the floor and fires upward. Some furnaces have side fired burners, such as in train locomotives. The burner tile is made of high temperature refractory and is where the flame is contained. Air registers located below the burner and at the outlet of the air blower are devices with movable flaps or vanes that control the shape and pattern of the flame, whether it spreads out or even swirls around. Flames should not spread out too much, as this will cause flame impingement. Air registers can be classified as primary, secondary and if applicable, tertiary, depending on when their air is introduced.

The primary air register supplies primary air, which is the first to be introduced in the burner. Secondary air is added to supplement primary air. Burners may include a pre-mixer to mix the air and fuel for better combustion before introducing into the burner. Some burners even use steam as premix to preheat the air and create better mixing of the fuel and heated air. The floor of the furnace is mostly made of a different material from that of the wall, typically hard castable refractory to allow technicians to walk on its floor during maintenance.

A furnace can be lit by a small pilot flame or in some older models, by hand. Most pilot flames nowadays are lit by an ignition transformer (much like a car’s spark plugs). The pilot flame in turn lights up the main flame. The pilot flame uses natural gas while the main flame can use both diesel and natural gas. When using liquid fuels, an atomizer is used, otherwise, the liquid fuel will simply pour onto the furnace floor and become a hazard. Using a pilot flame for lighting the furnace increases safety and ease compared to using a manual ignition method (like a match).

Sootblower [ edit ]

Sootblowers are found in the convection section. As this section is above the radiant section and air movement is slower because of the fins, soot tends to accumulate here. Sootblowing is normally done when the efficiency of the convection section is decreased. This can be calculated by looking at the temperature change from the crossover piping and at the convection section exit.

Sootblowers utilize flowing media such as water, air or steam to remove deposits from the tubes. This is typically done during maintenance with the air blower turned on. There are several different types of sootblowers used. Wall blowers of the rotary type are mounted on furnace walls protruding between the convection tubes. The lances are connected to a steam source with holes drilled into it at intervals along its length. When it is turned on, it rotates and blows the soot off the tubes and out through the stack.

Stack [ edit ]

Stack damper

The flue gas stack is a cylindrical structure at the top of all the heat transfer chambers. The breeching directly below it collects the flue gas and brings it up high into the atmosphere where it will not endanger personnel.

The stack damper contained within works like a butterfly valve and regulates draft (pressure difference between air intake and air exit) in the furnace, which is what pulls the flue gas through the convection section. The stack damper also regulates the heat lost through the stack. As the damper closes, the amount of heat escaping the furnace through the stack decreases, but the pressure or draft in the furnace increases which poses risks to those working around it if there are air leakages in the furnace, the flames can then escape out of the firebox or even explode if the pressure is too great.

Insulation [ edit ]

Insulation is an important part of the furnace because it improves efficiency by minimizing heat escape from the heated chamber. Refractory materials such as firebrick, castable refractories and ceramic fibre, are used for insulation. The floor of the furnace are normally castable type refractories while those on the walls are nailed or glued in place. Ceramic fibre is commonly used for the roof and wall of the furnace and is graded by its density and then its maximum temperature rating. For example, 8# 2,300 °F means 8 lb/ft3 density with a maximum temperature rating of 2,300 °F. The actual service temperature rating for ceramic fiber is a bit lower than the maximum rated temperature. (i.e. 2300 °F is only good to 2145 °F before permanent linear shrinkage).

Foundations [ edit ]

Concrete pillars are foundation on which the heater is mounted. They can be four nos. for smaller heaters and may be up to 24 nos. for large size heaters. Design of pillars and entire foundation is done based on the load bearing capacity of soil and seismic conditions prevailing in the area. Foundation bolts are grouted in foundation after installation of the heater.

Access doors [ edit ]

The heater body is provided with access doors at various locations. Access doors are to be used only during shutdown of heater. The normal size of the access door is 600×400 mm, which is sufficient for movement of people/ material into and out of the heater. During operation the access doors are properly bolted using leak proof high temperature gaskets.

See also [ edit ]

References [ edit ]

API 560 Fired Heater Design

Convection Section This article is a general introduction into some of the main considerations necessary when designing the Convection Section of a Fired Heater. The detailed heat transfer calculations and correlations are not detailed within this article (for more details on such procedures, please feel free to contact us).

The main purpose of the convection section is to absorb energy from the hot flue gas leaving the radiant section. The convection Section usually consists of bare and finned tube bundles and plays a crucial role in maximising the efficiency of the heater. As the name suggests, the primary mode of heat transfer within this area is ‘Convective’.

Often the lowest 2 or 3 rows are bare tube, whilst the remaining rows are typically finned tubes. The purpose of the fins is to increase the surface area for heat transfer. The heater designer will use a combination of no. of tube rows, the length of the tubes and the extent of finning, in order to adjust the surface area for heat transfer.

There are 3 main type of extended surfaces that are most commonly used in Convection Sections tubes, as shown below:

Convection Section Tube Types

Studs are most commonly used with heaters firing Fuel Oil, since deposits from the flue gas can more easily be cleaned from studded tubes than Serrated or Solid Finned tubes, which are more commonly used for heaters firing gaseous fuels. Sootblower lanes are usually incorporated into the design to allow for tube cleaning (either by manual steam lances or automated retractable systems).

Note: API 560 defines the acceptable dimensions of each of these extended surface types.

Flue Gas Pressure Drop

One of the important areas of consideration is the pressure drop of the flue gas as it flows over the tube bundles. The size of the stack is directly influenced by this factor, since a larger stack will be required to create sufficient draft to overcome these flue losses and maintain -2.5 mm(H2O)g at the arch (as per API 560 requirements).

One way of mitigating the impact on the stack size is to utilise an Induced Draft Fan (ID Fan), which will be designed to pull the flue gas through the tube bundle and any associated ducting.

Appropriate Size for Radiant Section The Convection Section is usually mounted on top of the Radiant Section (although some designs may have ‘off-set’ convection sections). This means that designer will have to carefully select the ‘Number of Rubes Per Row’ AND the ‘Tube Length’ appropriately in order to fit inside the radiant section footprint.

In addition, the heater designer needs to ensure that the No. of Tubes Per Row is suitable for the overall number of process flow passes within the heater.

Additional Process Streams

Flue Gas Pressure Drop The convection section also offers a convenient location for heating additional process streams, such as Steam Generation or Boiler Feed Water (BFW). The tubes with these streams may have a different tube size and ‘No. of Tubes Per Row’ to the main process coils. The additional of such secondary process streams can help to improve the overall efficiency and energy management of the site in general, not just the heater.

Insulation The convection section is usually lined with Castable Refractory, with the hot face usually having the robust/dense layer material. However, in recent years, convection sections are commonly being designed with Ceramic Fibre lining in order to minimise weight and ramp up times during start up (which must be steadily carried out when using Castable refractory).

New World Encyclopedia

Tiangong Kaiwu Illustrations of Chinese silversmiths smelting silver ore and separating lead from it. Taken from encyclopedia (1637), by Song Yingxing (1587-1666).

A furnace (from the Latin word fornax, meaning “oven”) is an appliance that produces heat. The heat in a furnace is usually produced by combustion of a fuel such as oil, wood, or natural gas. The heat may also be generated by electricity, as in an electric arc furnace, or by induction heating in an induction furnace.

In American English, the term furnace generally refers to the central heater in a home or office, or the heater for an industrial process, and sometimes it is a synonym for kiln, a device used in the production of ceramics. In British English, the term furnace almost exclusively means an industrial furnace, whereas a household heater is called a boiler or heater. Industrial furnaces are used for many applications, such as the extraction of metals from ores (smelting), the running of chemical reactions, or the refining of oil by fractional distillation.

Household Furnaces

A household furnace is a major appliance that is permanently installed to provide heat to an interior space through intermediary fluid movement, which may be air, steam, or hot water. The most common fuel source for modern furnaces in the United States is natural gas; other common fuel sources include LPG (liquefied petroleum gas), fuel oil, coal or wood. In some cases electrical resistance heating is used as the source of heat, especially where the cost of electricity is low.

Combustion furnaces always need to be vented to the outside. Traditionally, this was through a chimney, which tends to expel heat along with the exhaust. Modern high-efficiency furnaces can be 98 percent efficient and operate without a chimney.[1] The small amount of waste gas and heat are mechanically ventilated through a small tube through the side or roof of the house.

Modern household furnaces are classified as condensing or non-condensing, based on their efficiency in extracting heat from exhaust gases. Furnaces with efficiencies greater than approximately 89 percent extract so much heat from the exhaust that water vapor in the exhaust condenses; they are referred to as condensing furnaces. Such furnaces must be designed to avoid the corrosion that this highly acidic condensate might cause and may need to include a condensate pump to remove the accumulated water. Condensing furnaces can typically deliver savings of 20-35 percent in heating costs, if the old furnace was in the 60 percent Annual Fuel Utilization Efficiency (AFUE) range.

Heat Distribution

The furnace transfers heat to the living space of the building through an intermediary distribution system. If the distribution is through hot water (or other fluid) or through steam, then the furnace is more commonly termed a boiler. One advantage of a boiler is that the furnace can provide hot water for bathing and washing dishes, rather than requiring a separate water heater. A disadvantage, however, is that when the boiler breaks down, it results in loss of both heat and hot water.

A condensing furnace

Air convection heating systems have been in use for over a century, but the older systems relied on a passive air circulation system, in which the higher density of cooler air caused it to sink into the furnace, and the lower density of warmer air caused it to rise in the ductwork. The two forces acted together to drive air circulation in a system, known as “gravity-feed.” The layout of the ducts and furnace was optimized for short, large ducts and the furnace was therefore referred to as an “octopus” furnace.

By comparison, most modern “warm air” furnaces typically use a fan to circulate air into the rooms of house and pull cooler air back to the furnace for reheating. This is called forced-air heat. Because the fan easily overcomes the resistance of the ductwork, the arrangement of ducts can be far more flexible than the octopus of old. In American practice, separate ducts collect cool air to be returned to the furnace. At the furnace, cool air passes into the furnace, usually through an air filter, through the blower, then through the heat exchanger of the furnace, from where it is blown throughout the building. One major advantage of this type of system is that it also enables easy installation of central air conditioning by simply adding a cooling coil at the exhaust of the furnace.

Air is circulated through ductwork, which may be made of sheet metal or plastic “flex” duct and insulated or uninsulated. Unless the ducts and plenums have been sealed using mastic or foil duct tape, the ductwork is likely to have a high leakage of conditioned air, possibly into unconditioned spaces. Another cause of wasted energy is the installation of ductwork in unheated areas, such as attics and crawl spaces; or ductwork of air conditioning systems in attics in warm climates.

The following rare but difficult-to-diagnose failure can occur. If the temperature inside the furnace exceeds a maximum threshold, a safety mechanism with a thermostat will shut the furnace down. A symptom of this failure is that the furnace repeatedly shuts down before the house reaches the desired temperature; this is commonly referred to as the furnace “riding the high limit switch.” This condition commonly occurs if the temperature setting of the high limit thermostat is set too close to the normal operating temperature of the furnace. Another situation may occur if a humidifier is incorrectly installed on the furnace and the duct that directs a portion of the humidified air back into the furnace is too large. The solution is to reduce the diameter of the cross-feed tube, or to install a baffle that reduces the volume of re-fed air.

Industrial process furnaces

An industrial furnace, or direct-fired heater, is an equipment that provides heat for a process or chemical reaction. Furnace designs vary as to their function, heating duty, type of fuel, and method of introducing combustion air. However, most process furnaces have some common features.

Fuel flows into the burner and is burnt with air provided from an air blower. A given furnace may have more than one burner, arranged in cells that heat a set of tubes. Burners can be floor-mounted, wall-mounted, or roof-mounted, depending on design. The flames heat the tubes, which in turn heat the fluid inside in the first part of the furnace known as the radiant section or firebox. In this chamber, where combustion takes place, the heat is transferred mainly by radiation to tubes around the fire in the chamber. The heating fluid passes through the tubes and is thus heated to the desired temperature.

The gases from the combustion are known as flue gas. After the flue gas leaves the firebox, most furnace designs include a convection section where more heat is recovered before venting to the atmosphere through the flue gas stack.

In industrial furnaces, a common approach is to heat a secondary fluid called a heat transfer fluid (HTF) that has high heat-transfer efficiency and may contain special additives (such as an anti-rust agent). This heated fluid is then circulated around the whole plant to heat exchangers to be used wherever heat is needed, instead of directly heating the product line, as the product or material may be volatile or prone to cracking at the furnace temperature.

Radiant section

The radiant section is where the tubes receive almost all their heat by radiation from the flame. In a vertical, cylindrical furnace, the tubes are vertical. Tubes can be vertical or horizontal, placed along the refractory wall or around the middle, or arranged in cells. Studs are used to hold the insulation together and on the wall of the furnace. They are placed about one foot (300 mm) apart in the following picture of the inside of a furnace. The tubes, which are reddish brown from corrosion, are carbon steel tubes and run the height of the radiant section. The tubes are a distance away from the insulation so that radiation can be reflected to the back of the tubes to maintain a uniform tube wall temperature. Tube guides at the top, middle, and bottom hold the tubes in place.

Convection section

The convection section is located above the radiant section, where it is cooler to recover additional heat. In this section, heat transfer takes place by convection, and the tubes are finned to increase heat transfer. The first two tube rows at the bottom of the convection section and the top of the radiant section form an area of bare tubes (without fins) and are known as the “shield section,” because they are exposed to plenty of radiation from the firebox and they also shield the convection section tubes, which are normally of less resistant material from the high temperatures in the firebox.

The area of the radiant section just before the flue gas enters the shield section and then the convection section is called the “bridge zone.” The term “crossover” is used to describe the tube that connects from the convection section outlet to the radiant section inlet. The crossover piping is normally located outside, so that the temperature can be monitored and the efficiency of the convection section can be calculated. The sightglass at the top allows personnel to observe the flame shape and pattern from above and to check for “flame impingement”—that is, whether the flame is touching the tubes, causing small, isolated spots of very high temperature.

Burner

The burner in a vertical, cylindrical furnace is generally located in the floor and fires upward. Some furnaces have side-fired burners, as in train locomotives. The burner tile is made of high-temperature refractory material that contains the flame. Air registers located below the burner and at the outlet of the air blower are devices with movable flaps or vanes that control the shape and pattern of the flame, whether it spreads out or swirls around. Flames should not spread out too much, as this will cause flame impingement.

Air registers can be classified as primary, secondary, and (if applicable) tertiary, depending on when the air is introduced. The primary air register supplies primary air, which is the first batch of air to be introduced in the burner. Secondary air is added to supplement primary air. Burners may include a premixer to mix the air and fuel for better combustion before introducing it into the burner. Some burners even use steam in the premix, to preheat the air and create better mixing of the fuel and heated air. The furnace floor is mostly made of a different material from that of the wall, typically hard castable refractory that allows technicians to walk on its floor during maintenance.

A furnace can be lit by a small pilot flame or (in some older models) matches. Most pilot flames nowadays are lit by an ignition transformer (much like a car’s spark plugs). The pilot flame in turn lights up the main flame. The pilot flame uses natural gas, while the main flame may use both diesel and natural gas. For liquid fuels, the fuel is passed through an atomizer, to prevent the liquid fuel from pouring onto the furnace floor and becoming a hazard. Using a pilot flame for lighting the furnace increases safety and ease (compared to using a match).

Sootblower

Sootblowers are found in the convection section. As this section is above the radiant section and air movement is slowed by the fins, soot tends to accumulate here. Sootblowing is normally done when the efficiency of the convection section is decreased. This can be calculated by looking at the temperature change from the crossover piping and at the convection section exit.

Sootblowers utilize flowing media such as water, air, or steam to remove deposits from the tubes. This is typically done during maintenance, with the air blower turned on. Several different types of sootblowers are available. Wall blowers of the rotary type are mounted on furnace walls protruding between the convection tubes. The lances are connected to a steam source with holes drilled into it at intervals along its length. When it is turned on, it rotates and blows the soot off the tubes and out through the stack.

Stack

The flue gas stack is a cylindrical structure at the top of the heat transfer chamber. The breeching directly below it collects the flue gas and releases it high in the atmosphere where it will not endanger personnel.

The stack contains a damper that works like a butterfly valve and regulates the draft (pressure difference between air intake and air outflow) in the furnace. The draft pulls the flue gas through the convection section. The stack damper also regulates the heat lost through the stack. As the damper closes, the amount of heat escaping the furnace through the stack decreases, but the pressure or draft in the furnace increases. This pressure increase poses risks to those working around the furnace if there are air leakages in the furnace, because the flames may then escape out of the firebox or even explode if the pressure is too high.

Insulation

Insulation is an important part of the furnace because it prevents excessive heat loss. Refractory materials such as firebrick, castable refractories, and ceramic fiber are used for insulation. The floors of the furnace are normally castable type refractories, while the refractories on the walls are nailed or glued in place. Ceramic fiber is commonly used for the roof and wall of the furnace and is graded by its density and then its maximum temperature rating. For example, a grade of “8# 2,300°F” means the material has a density of eight lb/ft3 and a maximum temperature rating of 2,300°F. An example of a material with castable composition is kastolite.

Metallurgical furnaces

In metallurgy, several specialized furnaces are used, a number of which are listed below.

Furnaces used in smelters: The blast furnace, used to reduce iron ore to pig iron Steelmaking furnaces, including: Puddling furnace Reverberatory furnace Bessemer converter Open hearth furnace Basic oxygen furnace Electric arc furnace Electric induction furnace

Furnaces used to remelt metal in foundries.

Furnaces used to reheat and heat treat metal for use in: Rolling mills, including tinplate works and slitting mills. Forges.

Vacuum furnaces to heat metals and other materials to very high temperatures, in the presence of a vacuum that reduces potential sources of contamination.

Outdoor wood-fired boilers

Description

An outdoor wood-fired boiler (OWB), also known as a waterstove, wood boiler, or outdoor wood furnace, is a heating technology that has grown in popularity in the northern United States. In most cases, an OWB looks like a small shack with metal siding. It is self-contained, connected to the building it heats through underground insulated water pipes. It contains a metal combustion chamber for a wood fire, surrounded by a water tank or water jacket. The fire heats the water, which is then circulated through the insulated water pipes into the building that is being heated. Once the hot water from the boiler reaches the building, the heat can be transferred to most existing heating systems and the building’s hot water supply.

A damper and fan on the boiler interacts with a thermostat in the building. If the building’s temperature falls, the thermostat triggers the damper to open, allowing more oxygen to enter the combustion chamber. As a result, the fire burns more intensely and raises the water temperature, thereby increasing the heat supplied to the building.

Benefits

OWBs offer several benefits that have increased their popularity. Their large combustion chamber accommodates more fuel than many other forms of wood heat, decreasing the number of times an owner has to add fuel to the fire. Home insurance may cost more for people who heat with an indoor form of wood heat than with an OWB.[2] Moreover, for people with a large supply of free wood and willing to invest the time to prepare the wood and stock the OWB, an OWB can be less expensive than heating with gas, oil, or electricity.

Controversy