You are looking for information, articles, knowledge about the topic nail salons open on sunday near me hydraulic ash handling system on Google, you do not find the information you need! Here are the best content compiled and compiled by the https://chewathai27.com/to team, along with other related topics such as: hydraulic ash handling system write the three advantages of hydraulic ash handling system, types of ash handling system in thermal power plant pdf, what is ash handling system, pneumatic ash handling system, mechanical ash handling system, bottom ash handling system, ash handling system diagram, wet ash handling system

Table of Contents

What are the ash handling system?

Ash handling refers to the method of collection, conveying, interim storage and load out of various types of ash residue left over from solid fuel combustion processes. The most common types of ash resulting from the combustion of coal, wood and other solid fuels.

What is hydraulic pneumatic type ash handling system?

CLASSIFICATION OF ASH HANDLING SYSTEMS:

Hydraulic System: In this system, ash from the furnace grate falls into a system of water traveling at a high-pressure and is carried to the sumps. It is generally used in large power plants. The hydraulic system is generally used for intermittent ash disposal figures.

What is the important feature of hydraulic ash handling system?

3. What is the important feature of hydraulic ash handling system? Explanation: Particularly in hydraulic system the ash is actually quenched in water. So, there is less chance that ash has any possibility of getting in contact with the machineries.

How many types of ash handling systems are there?

2 Ash-Handling Plant. Ash-handling systems consist of the following major systems: Bottom ash (BA) system. Fly ash system (ESP/air heater)

How is ash removed from the boiler?

Most of the ash from a pulverized coal-fired boiler is carried through the boiler and air heater by the flue gas. As much as 50 to 70% of the ash generated by combustion of pulverized coal is removed from the flue gas by a particulate control device, such as a fabric filter or ESP.

What is ash slurry disposal system?

The ash slurry disposal takes placed based on a sloped disposal concept thereby it spreads and solidifies, leaving hardly any residual ash to fly off. The system has unique advantages of less land area requirement, lesser leaches in the disposal area, low velocity system, lesser size pipes and less power consumption.

Why is it important to prepare ash handling system?

Why is it important to prefer ash handling systems? Explanation: Considering the large coal burning capacity plant of modern times, the amount of ash produced when the coal is burnt is in thousands of tones. It could have an effect on other subjects too if the proper ash handling methods are not followed.

What is in fly ash?

Fly ash consists primarily of oxides of silicon, aluminum iron and calcium. Magnesium, potassium, sodium, titanium, and sulfur are also present to a lesser degree. When used as a mineral admixture in concrete, fly ash is classified as either Class C or Class F ash based on its chemical composition.

What is AHP power plant?

Abstract. The Analytic Hierarchy Process (AHP) method is used to prioritize plant assets according to their criticality. The Analytic Hierarchy Process (AHP) method allows the decision makers to model the problem into hierarchical structure with relationship between goal, objectives and alternatives.

What are the principal requirements of a good ash handling plant?

- Instrument air pressure not low.

- Conveying pressure not low.

- Silo level not high.

Which type of ash handling system works on Cyclone principle?

Explanation: cyclone separators use air to swirl around the ash that has been dispensed into them. due to centrifugal action heavier ash settles down, where as lighter dust/ash particles is collected in hopper and dumped out.

Why ash handling is more difficult than coal handling?

A large quantity of ash produced in steam power plants using coal. Ash produced is about 10 to 20% of the total coal burnt in the furnace. . Handling of ash is a problem because ash coming out of the furnace is too hot, it is dusty and irritating to handle and is accompanied by some poisonous gases.

What are the advantages and disadvantages of pneumatic conveyor?

- Lower required maintenance. …

- Increased safety. …

- Less spillage and dust leakage. …

- Better sanitation. …

- Enhanced flexibility. …

- Less energy efficiency. …

- Larger dust collection system is required.

What are the methods used for handling of coal?

- Belt conveyors.

- Screw conveyors.

- Vee bucket elevator.

- Pivoted bucket conveyor.

- Grab bucket conveyor.

- Flight conveyor.

- Skip hoists.

- Mass flow conveyor.

What are the difficulties encountered in ash handling?

Given the fine particle size, frictional nature and high temperature, fly ash can be a difficult material to handle reliably. In this article, we will look at various types of flow problems that can occur in fly ash handling and storage systems, including arching, ratholing, flow rate limitations and flooding.

Classification of Ash Handling System

- Article author: www.brainkart.com

- Reviews from users: 17516

Ratings

- Top rated: 4.5

- Lowest rated: 1

- Summary of article content: Articles about Classification of Ash Handling System In this system, ash from the furnace grate falls into a system of water possessing high velocity and is carried to the sumps. It is generally … …

- Most searched keywords: Whether you are looking for Classification of Ash Handling System In this system, ash from the furnace grate falls into a system of water possessing high velocity and is carried to the sumps. It is generally … Mechanical and Electrical : Power Plant Engineering : Coal Based Thermal Power Plants | Classification of Ash Handling System | i) Hydraulic system

ii) Pneumatic system

iii) Mechanical systemThe commonly used ash discharge equipment is as follows:

i) Rail road cars

- Table of Contents:

Ash Handling Systems | Nederman National Conveyors

- Article author: nationalconveyors.com

- Reviews from users: 41347

Ratings

- Top rated: 4.3

- Lowest rated: 1

- Summary of article content: Articles about Ash Handling Systems | Nederman National Conveyors Updating …

- Most searched keywords: Whether you are looking for Ash Handling Systems | Nederman National Conveyors Updating A typical ash handling system may employ vacuum pneumatic ash collection with ash conveying from several ash pick up stations and resulting in delivery to an ash storage silo for interim holding prior to load out for disposal or reuse. Pressurized pneumatic ash conveying may also be employed.

- Table of Contents:

What is Ash Handling

Ash Handling Capabilities

More About Ash Handling Systems

hydraulic ash handling system

- Article author: www.mbl.in

- Reviews from users: 33008

Ratings

- Top rated: 3.4

- Lowest rated: 1

- Summary of article content: Articles about hydraulic ash handling system Updating …

- Most searched keywords: Whether you are looking for hydraulic ash handling system Updating

- Table of Contents:

Energy Engineering Interview Questions and Answers – Sanfoundry

- Article author: www.sanfoundry.com

- Reviews from users: 42159

Ratings

- Top rated: 3.4

- Lowest rated: 1

- Summary of article content: Articles about Energy Engineering Interview Questions and Answers – Sanfoundry Updating …

- Most searched keywords: Whether you are looking for Energy Engineering Interview Questions and Answers – Sanfoundry Updating

- Table of Contents:

1000 Energy Engineering MCQs

1000 Energy Engineering MCQs

ScienceDirect

- Article author: www.sciencedirect.com

- Reviews from users: 408

Ratings

- Top rated: 4.9

- Lowest rated: 1

- Summary of article content: Articles about ScienceDirect Updating …

- Most searched keywords: Whether you are looking for ScienceDirect Updating

- Table of Contents:

hydraulic ash handling system

- Article author: www.mbl.in

- Reviews from users: 42378

Ratings

- Top rated: 3.9

- Lowest rated: 1

- Summary of article content: Articles about hydraulic ash handling system The hydraulic system is generally used for intermittent ash disposal figures. In this method water at sufficient pressure is used to take away … …

- Most searched keywords: Whether you are looking for hydraulic ash handling system The hydraulic system is generally used for intermittent ash disposal figures. In this method water at sufficient pressure is used to take away …

- Table of Contents:

Various Ash Handling Systems

- Article author: www.deepakkumaryadav.in

- Reviews from users: 13670

Ratings

- Top rated: 4.2

- Lowest rated: 1

- Summary of article content: Articles about Various Ash Handling Systems Various ash handling systems used are : Hydraulic ash handling system. Pneumatic ash handling system. Mechanical system. …

- Most searched keywords: Whether you are looking for Various Ash Handling Systems Various ash handling systems used are : Hydraulic ash handling system. Pneumatic ash handling system. Mechanical system. ash handling system diagram

ash handling system design

ash handling system define

ash handling system meaning

ash handling system power plant

Deepak - Table of Contents:

IV Characteristics of MOSFET

Sodium Vapour Lamp Construction and Working

ENERGY CONSERVATION ACT 2001 (IMPORTANT FEATURES)

Star Delta Starter Controlling Diagram Working of Star Delta Starter

Ash handling system

- Article author: www.slideshare.net

- Reviews from users: 2019

Ratings

- Top rated: 3.5

- Lowest rated: 1

- Summary of article content: Articles about Ash handling system 7. HYDRAULIC SYSTEM : • Ash from the furnace grate, falls into a system of water possessing high velocity and is carried to the sumps. • It is generally … …

- Most searched keywords: Whether you are looking for Ash handling system 7. HYDRAULIC SYSTEM : • Ash from the furnace grate, falls into a system of water possessing high velocity and is carried to the sumps. • It is generally … Total description on ASH HANDLING SYSTEM

- Table of Contents:

Recommended

Recommended

More Related Content

You have now unlocked unlimited access to 20M+ documents!

Just for you FREE 60-day trial to the world’s largest digital library

Steam Boiler: Hydraulic & Mechanical Ash Handling Equipment

- Article author: steamofboiler.blogspot.com

- Reviews from users: 4720

Ratings

- Top rated: 3.8

- Lowest rated: 1

- Summary of article content: Articles about Steam Boiler: Hydraulic & Mechanical Ash Handling Equipment The hydraulic system applies high pressure water jet to take bottom ash from hopper which was located under steam boiler or under stoker. The … …

- Most searched keywords: Whether you are looking for Steam Boiler: Hydraulic & Mechanical Ash Handling Equipment The hydraulic system applies high pressure water jet to take bottom ash from hopper which was located under steam boiler or under stoker. The …

- Table of Contents:

Related Post

steam boiler update

Clinker Hopper / Hydraulic Conveying System | Kawasaki Heavy Industries

- Article author: global.kawasaki.com

- Reviews from users: 39388

Ratings

- Top rated: 4.6

- Lowest rated: 1

- Summary of article content: Articles about Clinker Hopper / Hydraulic Conveying System | Kawasaki Heavy Industries The Hydraulic Conveying System is a typical bottom ash handling system adopted by many domestic coal-fired power plants. This system has basically two … …

- Most searched keywords: Whether you are looking for Clinker Hopper / Hydraulic Conveying System | Kawasaki Heavy Industries The Hydraulic Conveying System is a typical bottom ash handling system adopted by many domestic coal-fired power plants. This system has basically two … Learn about About Clinker Hopper / Hydraulic Conveying System – Kawasaki Heavy Industries, Ltd. “Powering your potential.”Clinker Hopper / Hydraulic Conveying System,Products,Plant & Infrastructure Company

- Table of Contents:

Mobility

Energy

Industrial Equipment

Leisure

Corporate Info

Feature

Handling System

Our Products

See more articles in the same category here: Chewathai27.com/to/blog.

Classification of Ash Handling System

Classification of Ash Handling System

i) Hydraulic system

ii) Pneumatic system

iii) Mechanical system

The commonly used ash discharge equipment is as follows:

i) Rail road cars ii) Motor truck iii) barge

Hydraulic System

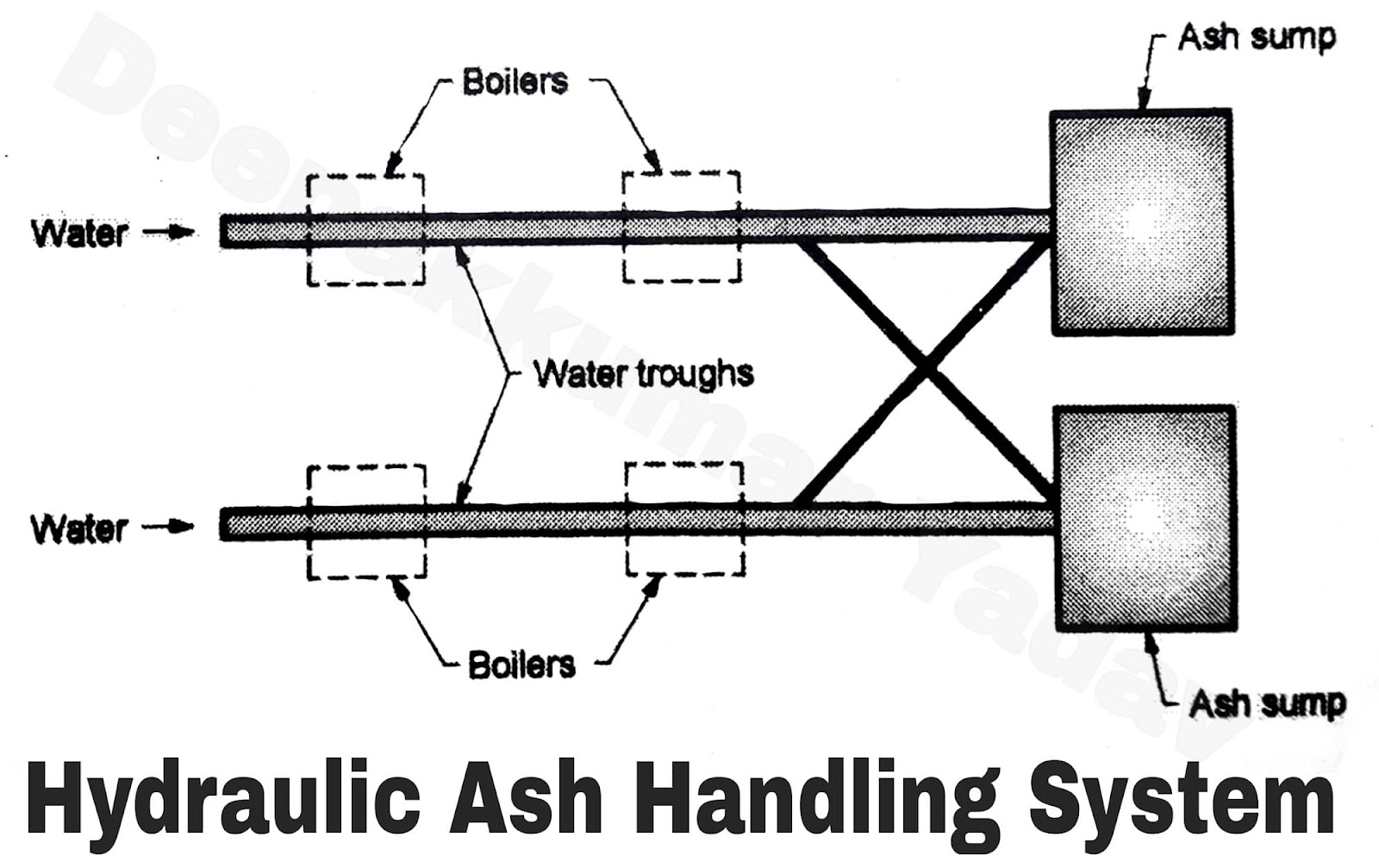

In this system, ash from the furnace grate falls into a system of water possessing high velocity and is carried to the sumps. It is generally used in large power plants. Hydraulic system is of two types, namely, low pressure hydraulic system used for intermittent ash disposal figure. Figure shows hydraulic system.

Figure: Hydraulic system

In this method water at sufficient pressure is used to take away the ash to sump. Where water and ash are separated. The ash is then transferred to the dump site in wagons, rail cars to trucks. The loading of ash may be through a belt conveyor, grab buckets. If there is an ash basement with ash hopper the ash can fall, directly in ash car or conveying system.

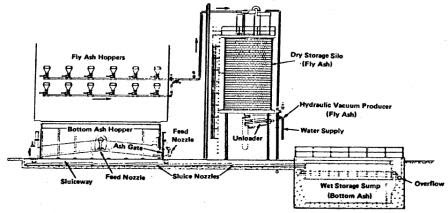

Water jetting of ash is shown in figure. In this method a low pressure jet of water coming out of quenching nozzle is used to cool the ash. The ash falls into trough and is then removed.

Pneumatic System

In this system ash from the boiler furnace outlet falls into a crusher where a lager ash particles are crushed to small sizes. The ash is then carried by a high velocity air or steam to the point of delivery. Air leaving the ash separator is passed through filter to remove dust etc. So that the exhauster handles clean air which will protect the blades of the exhauster.

Figure: Pneumatic system

Mechanical system

Figure: Mechanical system

Figure shows a mechanical ash handling system. In this system ash cooled by water seal falls on the belt conveyor and is carried out continuously to the bunker. The ash is then removed to the dumping site from the ash banker with the help of trucks.

Ash Handling Systems

Ash Handling Systems

What is Ash Handling?

Ash handling refers to the method of collection, conveying, interim storage and load out of various types of ash residue left over from solid fuel combustion processes.

The most common types of ash resulting from the combustion of coal, wood and other solid fuels.

bottom ash

bed ash

fly ash

ash clinkers

Ash handling systems may employ different forms of pneumatic ash conveying or mechanical ash conveyors.

A typical ash handling system may employ vacuum pneumatic ash collection with ash conveying from several ash pick up stations and resulting in delivery to an ash storage silo for interim holding prior to load out for disposal or reuse. Pressurized pneumatic ash conveying may also be employed.

Coarse ash material such as bottom ash is most often crushed in clinker grinders (crushers) prior to being transported in the ash conveyor system.

Very finely sized fly ash often accounts for the major portion of the material conveyed in an ash handling system. It is collected from baghouse type dust collectors, electrostatic precipitators and other apparatus in the flue gas processing stream.

Ash mixers (conditioners) and dry dustless telescopic devices are used to prepare ash for transfer from the ash storage silo to transport vehicles.

Pipe & Fittings

Ash Receivers

Double Dump Gate Airlock Valves

Rotary Airlock Feeders

Disc Type Ash Intake Valve

Exhausters (Vacuum Pneumatic System)

Blowers (Pressure Pneumatic System)

Dust Collectors

Ash Conditioners

Dry Unloaders

Clinker Grinders

Storage Silos

Bottom Ash Hoppers

Computerized Controls

Ash Handling Capabilities

Energy Engineering Interview Questions and Answers

This set of Energy Engineering Interview Questions and Answers focuses on “Coal and Ash Handling System – 2”.

1. _________ is used in high pressure hydraulic ash handling system, to quench the ash.

a) Turbines

b) Lubricants

c) Water troughs

d) Nozzle sprays

View Answer

Answer: d

Explanation: As we know Nozzles are used to increase pressure. Also, they are also used to quench the ash. The ash falling from the conveyor belt is quenched to make it flow down through the sump. Water trough is used in order to avoid dust creating from falling ash from the furnace.

advertisement

2. Which of the following ash handling system is more suitable for large thermal plants?

a) Steam jet ash handling system

b) Mechanical ash handling system

c) Pneumatic ash handling system

d) Hydraulic ash handling system

View Answer

Answer: d

Explanation: Hydraulic ash handling system is more suitable large thermal plants since its ash carrying capacity is considerably large. And also it has ability to dissolve the ash in the water which makes its capacity large. It also has lots of advantages it is clean, dust free and no noise is produced. The water used can be recycled only for limited amount of times.

3. What is the important feature of hydraulic ash handling system?

a) It is clean and dustless

b) It can discharge ash for long distances

c) The unhealthy aspect of ordinary ash basement work is eliminated

d) Absence of working parts in contact with ash

View Answer

Answer: d

Explanation: Particularly in hydraulic system the ash is actually quenched in water. So, there is less chance that ash has any possibility of getting in contact with the machineries. There is less chances of machine falling into a repair and maintenance is less as compared to any other type of ash handling system.

advertisement

advertisement

4. In hydraulic ash handling system, large quantities of leachate under a positive pressure head in pond pose a constant threat to ________

a) cause pungent smell

b) the livelihood

c) ground water quality

d) the nearby flora

View Answer

Answer: b

Explanation: Since there is constant gravity pressure that is exerting on the surface of the ponds or other water bodies where hydraulic ash is dumped. When the same water is absorbed into the ground, it affects the quality of ground water. This effect indirectly affects growth of plants and degrades the land around water body making it unusable.

5. Which of the following ash handling system is not flexible to re-locate/re-place its discharging site?

a) Steam jet ash handling system

b) Mechanical ash handling system

c) Hydraulic ash handling system

d) Pneumatic ash handling system

View Answer

Answer: c

Explanation: Since the hydraulic ash handling system involves the usage of liquids, the discharging sites cannot be re-located/re-placed. Else constructing/developing a new discharging site is possible but the old one cannot be replaced since it is a wet system. In case of all other forms of ash handling system it is easy since they are dry system and they won’t have much of an impact on the following discharging site/land.

advertisement

6. ___________ and __________ are the common problems on pipeline inner walls when the slurry contains calcium, magnesium and sulphate ashes.

a) Clogs and Corrosion

b) Scaling and Cracks

c) Pores and Contamination

d) Scaling and Cementation

View Answer

Answer: d

Explanation: Scaling and Cementation are the two main problems caused on the inner walls of pipeline, when there is contamination of calcium, magnesium and sulphate in the discharge. Calcium or magnesium contained mixtures have limited solubility. So, they intend get deposited on the materials.

7. Which of the following ash is suitable for selling?

a) Bed ash

b) Synthetic gypsum

c) Fly ash

d) Clinkers

View Answer

Answer: c

Explanation: Fly ash is sold in the market, which is used in concrete bricks, cement clinkers, road subbase and as mineral filler in asphaltic concrete. Fly ash is very fine in its structure, composed mostly of silica made from burning of coal in the furnace or boiler. And ‘Bed ash’ refers to the ash that’s struck on the walls of boiler which is very coarse in nature.

advertisement

8. Which ash handling system can be built up in limited space?

a) Mechanical ash handling system

b) Pneumatic ash handling system

c) Hydraulic ash handling system

d) Steam jet ash handling system

View Answer

Answer: d

Explanation: Steam jet ash handling system can be constructed particularly when there is a limited amount of space is available because not much amount of space is required for its setup and operation. Pneumatic and hydraulic ash handling system require huge amount of space for their construction and operation. Steam jet ash handling system is used in small capacity plants.

9. In what form does the total ash produced in the furnace escapes through the chimney?

a) Fines

b) Aerosols

c) Gas

d) Cinder

View Answer

Answer: a

Explanation: Fines are the particles which vary in the size of 1 to 80 microns. These could easily get escaped into air via chimneys. About 80% of ash produce is in this range of microns and everything gets easily escaped into air and the rest is made use for other possible purposes.

advertisement

10. What is the capacity of the steam jet ash handling system?

a) 45tonnes/hour

b) 15tonnes/hour

c) 30tonnes/hour

d) 150tonnes/hour

View Answer

Answer: b

Explanation: The capacity of the steam jet ash handling system is limited 15tonnes/hour since the plant built up is in less space. And it has ability to remove ash through a horizontal distance of 200m. the operation of this system is noisy since steam jet of high velocity is produced in such a limited place.

11. What material is used in pipe linings for linking of steam jet system?

a) Nickel alloy

b) Graphite

c) Titanium

d) Copper alloy

View Answer

Answer: a

Explanation: The abrasive particles present in ash cause wear and tear in pipes due to high speed movement in pipes of steam jet system. Even chilled iron also can be used to line the pipes to overcome the following problem. And also avoiding bends and turns in pipes would reduce the damage of pipes.

12. What is the distance up to which steam jet ash handling system is capable of removing ashes?

a) 200m

b) 50m

c) 75m

d) 350m

View Answer

Answer: a

Explanation: Even though the size of the steam jet ash handling capacity is compact, the high velocity steam jet can easily remove the ashes up to 200m. Since it is small sized plant its capability to remove ashes is limited. The moisture of steam also makes the ash wet and it would gain a light amount of weight which becomes a bit difficult to move ash at a longer distances.

13. What measure to be taken to avoid the noise produced in the pneumatic ash handling system?

a) Passing ash at slower pace

b) Reducing swift turns and sharp bends

c) Broadening of pipe width

d) Reducing and crushing the size of the ash

View Answer

Answer: b

Explanation: The air and ash mixture moving through the pipe at high pressure tends to hit the walls at inner side of pipe when there are number of swift turns and sharp bends made. Avoiding them can reduce the noise up to 50%.

14. Is there any requirement of auxiliary steam producer in the steam jet ash handling system.

a) True

b) False

View Answer

Answer: b

Explanation: There is no requirement for any auxiliary steam producing unit since the steam required is drawn from the boiler present in the system. The steam drawn from the boiler is pressurized and then utilized. Non-requirement of auxiliary unit is advantageous as it would cut slack in the expenses of setting up the plant.

15. How much amount of steam is required to remove 1 ton of ash from the steam jet ash handling system?

a) 100kg

b) 450kg

c) 65kg

d) 200kg

View Answer

Answer: a

Explanation: 100 kg of steam is required to remove 1 ton of ash. Since the steam let out is at very high velocity, 1 ton of ash can be easily moved to compare and balancing to its weight ratio. And this wholesome amount of steam is generated by the boiler present in the plant.

Sanfoundry Global Education & Learning Series – Energy Engineering.

So you have finished reading the hydraulic ash handling system topic article, if you find this article useful, please share it. Thank you very much. See more: write the three advantages of hydraulic ash handling system, types of ash handling system in thermal power plant pdf, what is ash handling system, pneumatic ash handling system, mechanical ash handling system, bottom ash handling system, ash handling system diagram, wet ash handling system